Custom Electrical Enclosure Added Panel Manufacturer in China

Electrical Enclosure Added Panel is designed to expand the capacity and functionality of your control cabinets, electrical cabinets, and telecom signal enclosures. At Linkwellelectrics, we manufacture these panels with strict quality standards and provide engineering support, fast delivery, and reliable after-sales service to meet your project needs.

Electrical Enclosure Added Panel Step-by-Step

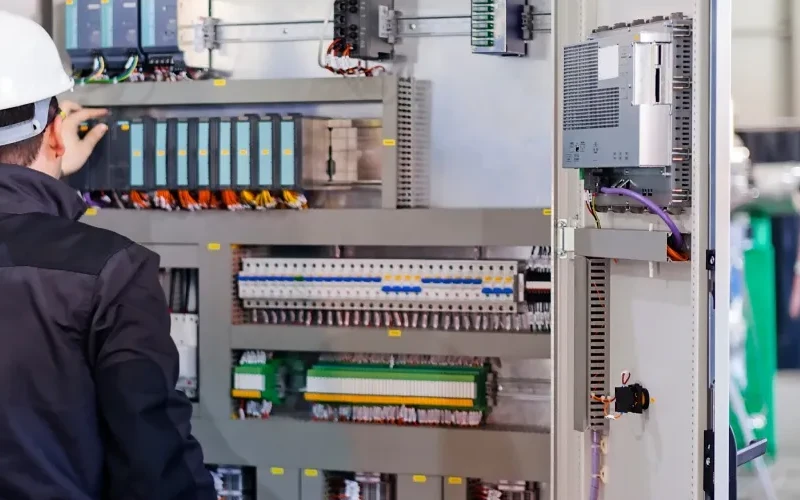

Planning and Designing

Create detailed electrical schematics and layouts based on production needs and safety standards (NFPA 70, UL508A). Ensure design includes power requirements, equipment specs, and safety measures for reliable, compliant operation.

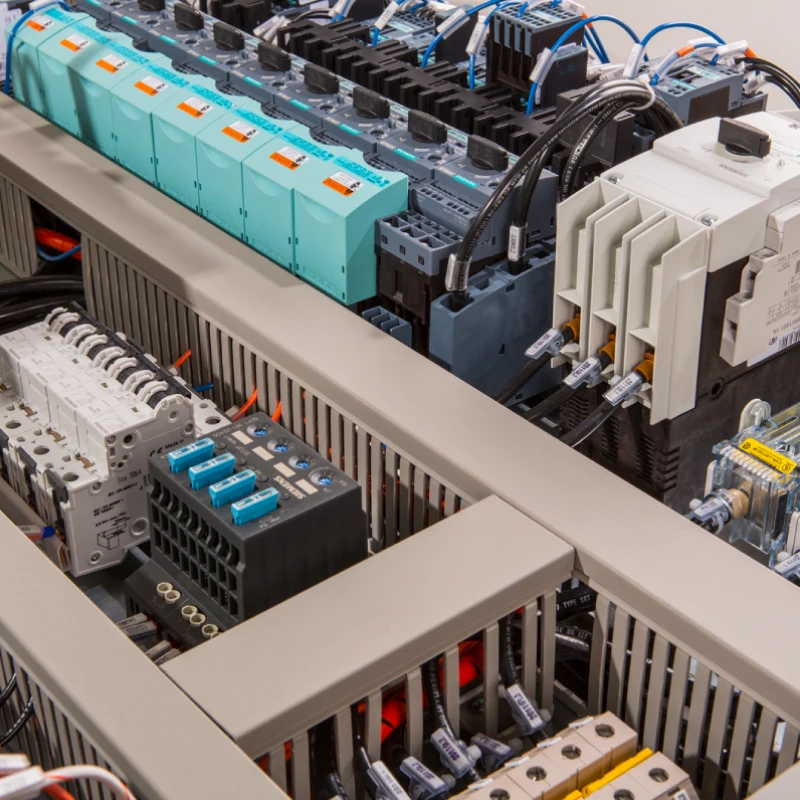

Component Layout And Design

Arrange components by function, thermal flow, and safety. Ensure proper spacing, ventilation, and grouping for AC/DC separation. Include schematics, internal space planning, and enclosure design for easy maintenance and expansion.

Assembling the Components

Mount components on a subpanel with DIN rails and wire ducts for organized wiring. Follow spacing requirements, include cooling elements, disconnects, and external interfaces to prepare for safe installation.

Installation and Wiring

Wire components according to schematics with proper gauge, color coding, and labeling. Ensure compliance with voltage standards (24VDC, 120VAC, 480VAC). Proper labeling supports easy troubleshooting and long-term maintenance.

Linkwell Electrics - Your Trusted Electrical Enclosure Added Panel Manufacturer from China

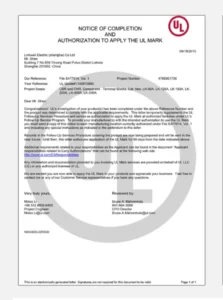

1. ISO 9001 and CE, UL certified, ensuring compliance with global safety standards.

2. IP65 and IP66 rated for superior dust and water resistance.

3. Corrosion-resistant materials extend service life in harsh conditions.

4. Large-scale production ensures stable supply and short lead times.

Working with us means you get a certified custom Electrical Enclosure and Electrical Enclosure Added Panel manufacturer delivering consistent quality and market-oriented solutions. We offer flexible production schedules to meet tight deadlines while controlling costs.

Global Partnership

Electrical Enclosure Added Panel Key Parts

Thermostat and Hygrostat

Types: Controls temperature/humidity, mechanical or electronic versions.

Performance: Maintains stable internal climate for sensitive equipment.

Durability: Built for continuous operation in industrial environments.

Integration: Works with heaters, fans, and cooling systems.

Fan and Filter

Types: Axial or centrifugal fans with replaceable filters.

Performance: Improves airflow, reduces overheating risk.

Durability: Corrosion-resistant housing for long service life.

Integration: Connects easily to thermostat control circuits.

Air Conditioner

Types: Top-mount, side-mount, or door-mount cooling units.

Performance: Maintains precise enclosure temperature in extreme climates.

Durability: IP-rated for dust and moisture protection.

Integration: Interfaces with enclosure monitoring systems.

Enclosure Lamp

Types: LED or fluorescent lighting fixtures.

Performance: Provides clear interior visibility during maintenance.

Durability: Shock-resistant and long-lasting light source.

Integration: Switch or door-contact controlled.

Enclosure Heater

Types: PTC or fan-assisted heaters.

Performance: Prevents condensation and freezing inside enclosures.

Durability: Designed for continuous safe heating.

Integration: Controlled by thermostats or hygrostats.

Terminal Blocks

Types: Screw, spring, or push-in connection models.

Performance: Ensures secure and organized wiring connections.

Durability: Flame-retardant housing, vibration-resistant.

Integration: Fits DIN rail mounting systems.

Control Transformer

Types: Step-down or isolation transformers.

Performance: Provides stable low-voltage control power.

Durability: High-quality windings for long-term reliability.

Integration: Supports various control circuit voltages.

CMS Cable Management

Types: Cable ducts, ties, and routing accessories.

Performance: Keeps wiring organized and protected.

Durability: Made from UV and impact-resistant materials.

Integration: Works with all standard enclosure layouts.

Push Button

Types: Momentary, maintained, or emergency stop switches.

Performance: Allows reliable manual control of equipment.

Durability: IP-rated for dust and water resistance.

Integration: Connects easily to control circuits.

Certificate

Key Features & Benefits

Discover how added panels enhance electrical enclosures with improved functionality and organization

Space Optimization

Maximize usable space within your enclosures for additional components and wiring, allowing for more compact designs.

Improved Organization

Create logical sections for different systems and maintain clean, professional layouts that simplify troubleshooting.

Easy Maintenance

Access components quickly with well-organized panels that simplify inspection, repair, and component replacement.

Enhanced Safety

Proper segregation of components reduces risks and improves overall system safety by preventing accidental contact.

Better Thermal Management

Strategic panel placement improves airflow and heat dissipation, preventing overheating of sensitive components.

Modular Design

Easily adapt and expand your enclosure system as needs change with modular added panel solutions.

Customize Your Electrical Enclosure Added Panel

Performance & Reliability

We ensure our panels provide precise electrical protection, maintaining stable performance and preventing costly equipment failures in industrial environments.

We use durable, high-quality materials that resist corrosion and wear, ensuring long-term reliability for every customized panel.

We design for uniform heat and load distribution, protecting all internal components and ensuring consistent operational efficiency.

Safety & Compliance

We manufacture panels meeting international safety standards, reducing risks and providing regulatory compliance confidence for buyers.

We integrate protective features like overcurrent and overheating safeguards to prevent damage and enhance workplace safety.

We rigorously test each panel, guaranteeing reliable performance and secure operation under diverse industrial conditions.

Customization & Flexibility

We offer tailored sizing, layout, and component options to match each buyer’s unique electrical enclosure requirements.

We provide flexible configurations for specific voltage, temperature, and control needs, optimizing panel performance.

We design panels for easy integration with existing systems, simplifying installation and minimizing downtime for clients.

Efficiency & Cost-effectiveness

We engineer panels to reduce energy consumption while maintaining optimal operation, saving operational costs for buyers.

We minimize maintenance through durable design, reducing labor, repair costs, and operational interruptions.

We provide competitive pricing and scalable production, ensuring quality custom panels meet any client budget or quantity requirements.

Electrical Enclosure Added Panel Ratings & Standards

| Category | Standard/Rating | Description |

|---|---|---|

| Ingress Protection | IP54, IP65, IP66 | Defines protection against dust and water entry. |

| UL Standards | UL508A | Ensures electrical panels meet safety requirements in North America. |

| Short Circuit Rating | Up to 65kA | Specifies maximum withstand current during faults. |

| Thermal Performance | IEC 61439 | Evaluates heat dissipation and safe operating temperatures. |

| Environmental Standards | NEMA Ratings | Determines suitability for indoor/outdoor use and harsh conditions. |

What are the Benefits of Electrical Enclosure Added Panel ?

Cost-Effective Expansion: Easily adds capacity to existing cabinets without full replacement, saving installation and downtime costs.

Improved System Flexibility: Enables integration of extra terminals, climate control, and accessories for better functionality.

Enhanced Safety & Compliance: Built to UL508A and IEC 61439 standards, ensuring long-term reliability in harsh environments.

Customer Testimonials

FAQ of Electrical Enclosure Added Panel

When should I use an Added Panel instead of a larger enclosure?

Added Panels are ideal when your existing enclosure lacks space, but a full replacement would be costly or time-consuming. They allow seamless expansion without changing your entire setup.

Are Added Panels compatible with all enclosures?

Most panels are designed to fit standard enclosure models, but compatibility depends on dimensions, mounting style, and certification requirements. We provide guidance to ensure a perfect fit.

Can I add climate control devices to an Added Panel?

Yes. Many Added Panels are designed to include thermostats, fans, or heaters. Proper integration ensures optimal airflow and thermal management.

What materials are used in Electrical Enclosure Added Panels?

Panels are commonly made from powder-coated steel, stainless steel, or aluminum. We also provide corrosion-resistant options for food, marine, or chemical industries.

Can you handle bulk orders with fast delivery?

Yes, our production capacity supports large-scale orders with lead times as short as 2 weeks for standard models.

All-in-one Electrical Enclosure Added Panel Solutions for Your Project

As a trusted Electrical Enclosure Added Panel supplier, we offer more than products—we deliver solutions. Our services include technical consultation, customized design, fast prototyping, on-site support, and international shipping. We ensure each panel fits your project’s operational, safety, and regulatory requirements.