You might be considering enclosure heating vs ventilated enclosure options for your electrical cabinets. The best choice depends on your specific environment. Enclosure heating is ideal for combating cold, moisture, and dust by preventing condensation and safeguarding sensitive electronics. On the other hand, ventilated enclosures excel in clean, dry, and temperature-controlled settings by providing effective cooling. Selecting between enclosure heating vs ventilated enclosure should be based on your climate, dust exposure, and maintenance requirements. Linkwell offers expert solutions to help you choose the perfect enclosure for your application.

Enclosure Heating and Ventilated Enclosure Key Takeaways

- Choose enclosure heating to protect electronics from cold, moisture, and condensation in damp or cold environments.

- Use ventilated enclosures to cool equipment in hot, dry, or clean settings by promoting airflow and heat removal.

- Combine heating and ventilation when your enclosure faces both cold nights and hot days for balanced climate control.

- Regular maintenance like cleaning filters, checking fans, and testing thermostats keeps your enclosure system efficient and reliable.

- Match your climate control choice to your environment, heat load, and equipment needs to save energy and avoid costly damage.

What Is Enclosure Heating?

Recommended products

You might wonder why enclosure heating matters for your building enclosure. It keeps the inside of your enclosure warm and dry, especially when cold weather hits. Heaters prevent condensation, freezing, and moisture buildup. This protects sensitive electronics and control panels from rust and electrical failure. You see enclosure heating used in places like data centers, telecommunications, and factories. There are different types of heaters, such as convection, radiant, and fan-forced. Some smart heaters even let you monitor and adjust settings remotely. With proper insulation, you get stable temperatures and less risk of damage.

Tip: Using a thermostat or hygrostat with your enclosure heater helps control humidity and temperature, making your system more efficient.

- Main functions of enclosure heating:

- Maintains stable internal temperature

- Prevents condensation and moisture

- Protects electronics from freezing

- Maximizes uptime and reliability

What Are Vented Enclosures?

Recommended products

Vented enclosures use ventilation to keep things cool inside your building enclosure. They rely on air circulation and vents to move heat out and bring fresh air in. You often see vented enclosures in industrial automation, power distribution, telecommunications, renewable energy, and transportation. Electrical enclosure vents, fan kits, and passive ventilation systems help regulate temperature and humidity. Good insulation and proper vent placement make a big difference. If you have high heat loads or work in a clean, dry environment, enclosure ventilation is a smart choice.

- Common applications for vented enclosures:

- Control panels and motor starters

- Transformers and circuit breakers

- Network equipment and outdoor systems

- Solar inverters and wind turbine controls

- HVAC and food processing equipment

Enclosure Heating vs Ventilated Enclosure Key Differences

Let’s compare enclosure heating and vented enclosures. Enclosure heating actively keeps your building enclosure warm and dry. It uses heat and insulation to prevent condensation and control humidity. Ventilated enclosures depend on airflow and vents for cooling. Passive ventilation works best when the outside air is clean and temperatures are moderate. If you have high humidity or risk of freezing, enclosure heating is better. If you need to remove excess heat from machinery or solar gain, enclosure ventilation is the way to go.

| Feature | Enclosure Heating | Vented Enclosures |

|---|---|---|

| Temperature Control | Active (uses heat) | Passive/Active (uses airflow) |

| Humidity Control | Precise (with hygrostats) | Depends on ambient air |

| Best For | Cold, humid environments | Hot, dry environments |

| Key Components | Heater, thermostat, insulation | Vents, fans, insulation |

Note: Restricted airflow or clogged filters can reduce ventilation efficiency, causing higher temperatures and humidity inside your enclosure.

Linkwell Solutions for Enclosure Climate Control

Linkwell stands out as a global leader in cabinet components. You get access to a wide range of enclosure heating and cooling solutions, designed for reliability and easy integration. Whether you need forced heating or forced ventilation, Linkwell’s products help you maintain the perfect climate inside your enclosure.

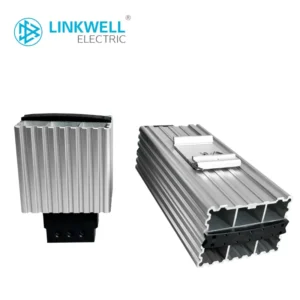

Linkwell Enclosure Heater

If you want to protect sensitive electronics from condensation or freezing, Linkwell enclosure heaters deliver dependable results. You can choose from models with PTC self-regulating technology, which means the heater adjusts its power automatically. These heaters come in compact, DIN-mountable designs, making installation quick and simple. You get options for voltage, power, and mounting style, so you can customize your setup. Linkwell enclosure heaters work well in telecom, EV charging, and industrial automation. They feature aluminum casings for corrosion resistance and IP65 ratings for dust and water protection. Every heater is tested for thermal and load limits, so you know it’s reliable.

- Key features:

- Prevent condensation and freezing

- Energy-efficient operation with thermostatic control

- Easy installation and customization

- Certified to CE, UL, ISO9001, and RoHS standards

Linkwell Electrical Enclosure Ventilation

When you need to keep things cool, Linkwell enclosure ventilation devices offer complete protection for your control cabinets. You can pick from fan kits, air vents, and heat exchangers. These forced ventilation devices help you manage heat and moisture, even in tough environments. Linkwell’s ventilation products come with CE, UL, and RoHS certifications, so you meet international safety standards. You get fast delivery, full client support, and options for customization. Linkwell’s reputation stretches across more than 60 countries, and you benefit from competitive pricing and prompt service.

Tip: Regularly check your vent filters and fans to keep your enclosure running smoothly.

| Certification | Region | Focus Area |

|---|---|---|

| UL 508A | U.S. & Canada | Control Panel Safety |

| NFPA 70 | U.S. & Canada | Electrical Installation |

| IEC 61439 | International | Low-voltage Assemblies |

Component Interaction: Heaters, Fans, Thermostats

You can combine forced heating and forced ventilation devices for the best climate control. Heaters keep your enclosure warm and dry, while fans and vents remove excess heat. Thermostats and hygrostats help you set the right temperature and humidity. This teamwork keeps your electronics safe and extends their lifespan. You get flexible solutions for any application, whether you need heating, cooling, or both.

- How components work together:

- Heaters prevent moisture and cold damage

- Fans and vents provide forced airflow for cooling

- Thermostats and hygrostats control temperature and humidity

- You can mix and match devices for custom climate control

Enclosure Heating vs Ventilated Enclosure

Energy Efficiency

When you compare enclosure heating vs ventilated enclosure, energy efficiency often depends on your climate and how you use insulation. In cold climates, enclosure heating works best when you combine it with strong insulation and airtight seals. This setup keeps the heat inside your building enclosure, so you use less energy to maintain a stable temperature. If you try to heat only with ventilation, you need to move a lot of air, which wastes energy and can make things uncomfortable.

Ventilated enclosures, especially those with forced air ventilation and heat recovery ventilators (HRVs), can save energy in cold zones if you size them correctly. HRVs help you recover heat from outgoing air, so you don’t lose as much warmth. In moderate climates, you might get by with passive ventilation or simpler systems that use less energy and cost less up front. The key is to balance insulation, airtightness, and the right heating and cooling method for your building enclosure.

Tip: Over-ventilating to provide heat can actually increase your energy bills. Use insulation and efficient heating or forced air ventilation for the best results.

Installation & Maintenance

You want a system that’s easy to install and maintain. With enclosure heating, you usually mount the heater inside your enclosure, connect it to a thermostat, and make sure the insulation is tight. Linkwell’s enclosure heaters come with DIN rail or panel mounting options, so you can set them up quickly. You don’t need to worry about outside air or dust getting in, especially with IP65-rated models.

Ventilated enclosures, on the other hand, need fans, vents, and sometimes filters. Forced air ventilation systems require you to check airflow paths, clean or replace filters, and inspect fans for dust or damage. You should also monitor vibration and noise, lubricate bearings, and keep the airflow clear. Maintenance for both systems includes cleaning panels, checking seals, and making sure everything runs smoothly. In harsh environments, you’ll want to do these tasks more often to prevent heat buildup or moisture problems.

- Common maintenance tasks:

- Clean and inspect heater elements, vents, and fan grills

- Check and replace filters in forced air ventilation systems

- Lubricate moving parts and tighten hardware

- Inspect seals and gaskets for leaks or wear

- Test thermostats and controls for accuracy

Cost & Lifespan

Cost is always a big factor in the enclosure heating vs ventilated enclosure debate. Enclosure heating systems usually have a lower upfront cost, especially if you already have good insulation in your building enclosure. They last a long time, especially when you use quality products like Linkwell’s CE and UL-certified heaters. You also save money on repairs because there are fewer moving parts.

Ventilated enclosures, especially those with forced air ventilation, can cost more to install because you need fans, filters, and sometimes heat exchangers. You’ll spend more on maintenance, too, since you need to replace filters and check fans regularly. However, in hot environments, ventilation can extend the lifespan of your electronics by keeping them cool. Both systems offer customization, so you can choose the best fit for your needs and budget.

| Feature | Enclosure Heating | Ventilated Enclosure |

|---|---|---|

| Upfront Cost | Lower (with insulation) | Higher (fans, filters, HRVs) |

| Maintenance | Minimal | Regular (filters, fans) |

| Lifespan | Long (few moving parts) | Long (with upkeep) |

| Customization | High (Linkwell options) | High (Linkwell options) |

Environmental Suitability

You need to match your system to your environment. Enclosure heating shines in cold, humid, or dusty places. It keeps your building enclosure dry and warm, preventing condensation and corrosion. Linkwell’s heaters, with their IP65 rating and tough aluminum housing, protect your electronics from dust and water.

Ventilated enclosures work best in clean, dry, and hot environments. Forced air ventilation removes excess heat, but in dusty or humid areas, you risk bringing in contaminants. Passive ventilation can help in moderate climates, but you need to watch for dust and moisture. If you work in a harsh setting, look for enclosures with high IP or NEMA ratings and use materials like aluminum or stainless steel for extra protection.

- In high humidity or dusty environments:

- Use tight seals, gaskets, and proper insulation to block dust and moisture.

- Choose enclosure heating to avoid condensation and rust.

- Avoid bringing in outside air unless you use filtered or closed-loop forced air ventilation.

- For passive ventilation, make sure filters are clean and vents are well-placed.

Note: Linkwell’s products meet strict international standards, so you get reliable performance and long-term protection in any environment.

Application Suitability

When to Use Enclosure Heating

You want to use enclosure heating when your equipment faces cold, damp, or unpredictable weather. If you manage outdoor control panels, security cameras, or highway traffic signs, you know how freezing temperatures and condensation can cause headaches. Enclosure heaters keep your electronics dry and safe, even in harsh environments. You’ll see these heaters in places like:

- ATMs and transaction drawers

- Switchgear cabinets and control valve housings

- Fast food signs and car wash kiosks

- Outdoor electrical power panels

- Pump houses and alarm systems

Enclosure heating also plays a big role in transportation, medical systems, and railway engineering. It prevents frost and condensation, which can lead to system failures or corrosion. If you work with sensitive equipment in cold climates, enclosure heating is your best friend.

Tip: If your enclosure sits outside or in a place with big temperature swings, a heater helps prevent costly downtime.

When to Use Vented Enclosures

Vented enclosures shine when your main challenge is heat. If your equipment generates a lot of internal heat—think VFDs, motor drives, or high-current transformers—ventilation keeps things cool and running smoothly. You’ll want vented enclosures if:

- Internal heat generation exceeds 150 W

- Component hotspots reach over 50 °C

- You operate in sunny, coastal, or industrial areas with big temperature swings

Industrial bakeries, wastewater utilities, and factories often switch to vented enclosures to cut failure rates and extend equipment life. Ventilation needs increase in environments with sun, rain, or salt exposure. Proper airflow prevents overheating, reduces corrosion, and keeps your system reliable.

Note: Regularly check your filters and fans to make sure your ventilation needs are met and your enclosure stays protected.

Combining Both Approaches

Sometimes, you need both heating and ventilation for the best results. Maybe your enclosure faces cold nights and hot days, or you want to control both moisture and heat. Combining these systems can offer:

| Benefit / Challenge | Description |

|---|---|

| Heat Dissipation | Ventilation removes excess heat, preventing equipment failure. |

| Moisture and Condensation Control | Airflow and heating together reduce humidity and stop corrosion. |

| Pressure Equalization | Vents balance pressure, protecting seals and enclosure integrity. |

| Safety | Proper design removes harmful gases and meets safety standards. |

| System Complexity | Combining systems needs careful planning to avoid wasted energy. |

| Maintenance | More components mean more upkeep—fans, filters, and controls. |

| Energy Implications | Poor coordination can waste energy if heating and ventilation overlap. |

You get the best results by using smart controls and regular maintenance. This way, your enclosure stays comfortable, efficient, and safe all year round.

Decision Guide

Checklist for Choosing

Ready to pick the right climate control for your enclosure? Use this checklist to make a confident choice:

- Assess Heat Load

Figure out how much heat your equipment generates. Small, dense electronics often need more cooling. - Check Ambient Conditions

Look at the temperature, humidity, dust, and contaminants around your enclosure. If you face high humidity or dust, you may need sealed solutions. - Decide on Temperature Range

Know the safe operating range for your components. Some need tight control to avoid damage. - Choose Cooling or Heating Method

For mild heat, natural convection works. For higher loads, use fans or blowers. If you need to keep out contaminants, consider closed-loop cooling or heating. - Plan Airflow and Mounting

Place fans or vents where they work best. Good placement improves cooling and keeps dust out. - Think About Isolation

Sensitive equipment may need to stay isolated from outside air. Sealed enclosures with heaters or air conditioners help here.

Common Mistakes

Many people make similar errors when choosing climate control for electrical enclosures. Watch out for these pitfalls:

- Picking a system without checking the local temperature, humidity, or dust levels.

- Ignoring the effects of moisture and corrosion, which can cause electrical failures.

- Failing to calculate the real heat load, leading to overheating or wasted energy.

- Oversizing air conditioners, which can cause poor humidity control and wear out compressors.

- Leaving enclosure doors open, exposing equipment to dust and wasting energy.

- Using cooling units that do not match the enclosure’s protection rating.

- Skipping regular maintenance, which leads to blocked filters and equipment breakdowns.

- Upgrading equipment without checking if your climate control can handle the extra heat.

FAQ

What’s the main difference between enclosure heating and ventilation?

Enclosure heating keeps things warm and dry, stopping condensation and freezing. Ventilation cools your enclosure by moving air, which helps in hot or sunny places. You pick based on your climate and equipment needs.

Can I use both heating and ventilation in one enclosure?

Yes, you can! Many setups need both. Heaters fight moisture and cold, while fans or vents remove extra heat. Smart controls help you balance both for the best protection.

How do I know if my enclosure needs a heater?

Look for signs like condensation, rust, or equipment failures in cold or damp spots. If your enclosure sits outdoors or in a humid area, a heater can save you from costly repairs.

How often should I check or maintain my enclosure climate system?

You should inspect heaters, fans, and filters every few months. Clean dust, check for wear, and test controls. Regular checks keep your system running smoothly and help prevent breakdowns.

Are Linkwell’s products certified for safety and quality?

Absolutely! Linkwell’s enclosure heaters and ventilation systems carry CE, UL, and RoHS certifications. You get reliable, safe, and internationally approved solutions for your electrical cabinets.

Conclusion

Choosing between enclosure heating and ventilated enclosures depends on your environment and application. You get the best results when you match your climate control to your needs. Linkwell’s integrated solutions help you protect your equipment, save energy, and simplify maintenance.

If you want to improve your setup, review your enclosure’s conditions, check heat loads, and consider expert advice. Reach out to Linkwell for custom guidance and reliable support.