You probably know how cooling systems keep equipment running smoothly. Without proper safety measures, unguarded fans can cause serious accidents. Your hands, clothing, or tools can easily get caught, putting safety at risk every time you work near these systems. Fan guards in cooling systems protect you and your equipment, making safety a top priority. When you choose the right guard, you boost safety and help your cooling system work reliably.

Key Takeaways

- Fan guards enhance safety by preventing accidents with spinning blades and keeping foreign objects out.

- Using the right fan guard protects your equipment from damage, reducing repair costs and downtime.

- Regularly check and clean fan guards to maintain airflow efficiency and extend the life of your cooling system.

- Choose the appropriate type of fan guard based on your environment to ensure optimal performance and safety.

- Investing in quality fan guards leads to long-term savings and improved reliability for your cooling systems.

Risks of Operating Without Fan Guards

Safety Hazards

You face real dangers when you work around cooling systems without fan guards. The spinning blades move fast and can cause serious injuries with just a quick touch. Here are some of the most common hazards you might encounter:

- Contact with rotating blades can lead to deep cuts or even amputations.

- Debris entering the fan may get shredded, turning into flying projectiles.

- Pinch points in belts or sheaves can trap fingers, causing painful injuries.

- Hot motor surfaces can burn your skin if you touch them before they cool down.

- Broken or loose guards can become hazards themselves if not properly secured.

Many workers report being within five feet of unguarded fans while doing their jobs. Fans often run at high speeds, sometimes reaching 3,600 rpm. You might need to access areas near these machines, which puts you in a zone of danger. That’s why industry standards require guards to protect people from moving parts and keep everyone safe.

Tip: Always check that fan guards are securely fastened before you start work. This simple step can prevent accidents and keep your workplace safe.

| Requirement | Description |

|---|---|

| Protect the People | Ensures safety from moving parts that could cause injury to workers. |

| Stay Safe and Secure | Guards must be securely fastened to function properly and prevent accidents. |

| Deter the Debris | Prevents external objects from interfering with the equipment, protecting both workers and machinery. |

| Do No Harm | Guards should be designed to avoid creating additional hazards, such as sparks or overheating. |

| Don’t Let the Grease Slide | Maintenance access must be considered in the design to allow for proper upkeep of machinery. |

Linkwell follows these standards closely, making sure every product meets strict safety requirements. You get peace of mind knowing your equipment is protected.

Equipment Damage

When you skip fan guards, you risk more than just personal injury. Your equipment can suffer, too. Dust and debris can easily enter the cooling system. Over time, this buildup clogs fans and erodes sensitive electronic components. You might notice your system running hotter than usual or even shutting down unexpectedly.

Objects that fall into an unguarded fan can break blades or jam the motor. This leads to expensive repairs and longer downtime. In some cases, flying debris can damage other parts of your system, causing a chain reaction of failures. You want your cooling system to last, so keeping it protected is key.

Linkwell’s fan guards help block dust and debris, keeping your equipment clean and running smoothly. You save money on repairs and avoid unnecessary headaches.

Reliability Issues

You rely on your cooling system to keep everything working. Without fan guards, you invite problems that hurt reliability and uptime. Dust and contaminants clog fans, slow airflow, and make your system less effective. Electronic components exposed to heat can fail, leading to costly downtime.

Industries like telecommunications and data centers depend on stable cooling for equipment longevity. If your cooling system fails, you risk losing valuable data or interrupting critical services. Effective cabinet cooling prevents overheating, which is crucial for improved system reliability.

The risks of operating without fan guards go beyond safety. You risk equipment damage and unreliable performance. Linkwell’s solutions help you meet industry standards, protect your investment, and keep your operations running without interruption.

Types of Fan Guards in Cooling Systems

You have a lot of choices when it comes to fan guards in cooling systems. Each type offers unique benefits, so picking the right one can make a big difference for safety and performance. Let’s break down the main types of fan guards you’ll see in cooling systems and how they fit into real-world applications.

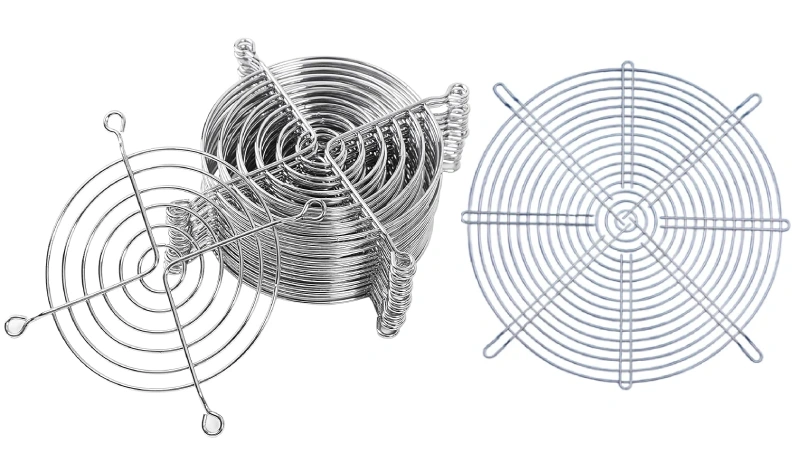

Steel Wire Guards

Steel wire guards are the classic choice for many cooling systems. You’ll spot them on Linkwell’s fan filter units and axial fans. These guards use sturdy metal wires to create a protective barrier. Here’s what makes them stand out:

- Keep your hands and tools away from fast-moving blades.

- Block debris, cables, and foreign objects from entering the fan.

- Help your cooling system last longer and work more efficiently.

| Feature/Advantage | Description |

|---|---|

| Noise Reduction | Steel wire guards help fans run quieter by blocking only a small amount of airflow. |

| Airflow Efficiency | You get up to 30% more airflow compared to solid sheet metal guards. |

| Heat Dissipation | These guards help remove heat, which keeps electronics safe and extends their life. |

| Safety | They protect you and your equipment from accidents and damage. |

You’ll find steel wire guards on industrial cooling systems and electrical enclosure fans where durability and airflow matter most.

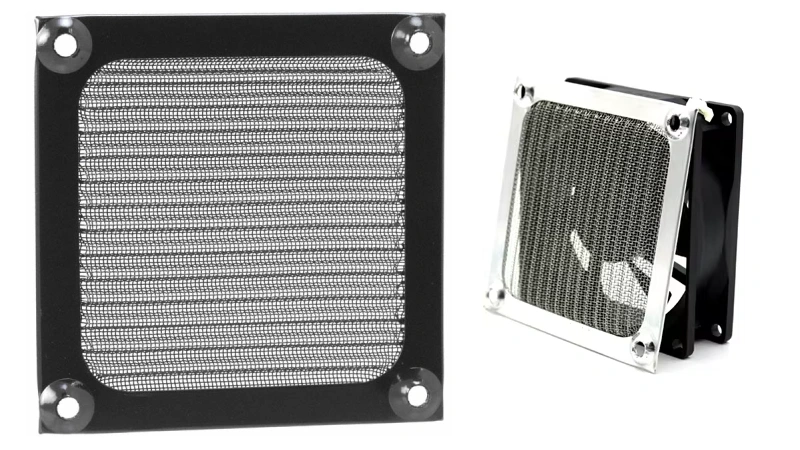

Wire Mesh Guards

Wire mesh guards offer a different style of protection. You’ll see them on Linkwell’s computer chassis fans and some enclosure fans. These guards use a fine mesh to shield sensitive parts while letting air flow freely.

- Great for computer case grilles.

- Used in industrial cooling systems to boost safety.

- Common in HVAC setups for ventilation and protection.

| Application Type | Description |

|---|---|

| Computer Case Grilles | Protects components while allowing airflow. |

| Industrial Cooling Systems | Shields machinery and enhances safety. |

| HVAC Systems | Provides ventilation and safety in heating/cooling. |

Wire mesh guards work well when you need extra protection from small debris but still want strong airflow.

Plastic Guards

Plastic guards are lightweight and easy to handle. You’ll find them on Linkwell’s fan filter units and some computer chassis fans. These guards suit home and light commercial cooling systems.

- Lighter than metal guards, which makes installation easier.

- More resistant to corrosion, so they last longer in humid places.

- Cost-effective for basic cooling needs.

| Feature | Metal Fan Guards | Plastic Fan Guards |

|---|---|---|

| Durability | Best for high-performance jobs | Good for home and light commercial use |

| Weight | Heavier, adds stability | Lighter, easy to install |

| Cost | More expensive | Budget-friendly |

| Corrosion Resistance | Less resistant | More resistant |

| Performance | Great in high heat | Quieter, ideal for home use |

When you choose fan guards in cooling systems, think about where you’ll use them and what you need most—durability, airflow, or quiet operation. Linkwell offers all types of fan guards, so you can match the right guard to your cooling system and keep everything running safely.

Role of Fan Guards for Cooling System Safety

Preventing Accidents

You want to feel safe when you work around cooling systems. The role of fan guards starts with keeping you and your team out of harm’s way. Fan guards act as a strong barrier between you and the spinning blades. They stop hands, tools, or clothing from getting caught. This simple feature brings enhanced safety to your workspace.

Take a look at how fan guards help, based on safety studies:

| Key Benefits of Fan Guards | Description |

|---|---|

| Enhanced Safety | Prevents accidental contact with moving blades, ensuring operator safety. |

| Compliance with Regulations | Supports compliance with workplace safety regulations, reducing liability concerns. |

| Essential Components | Fan guards are crucial for maintaining safety, reliability, and efficiency in cooling systems. |

You can see that enhanced safety is not just a bonus—it’s a must-have for any modern cooling system.

Protecting Equipment

Fan guards do more than protect people. They also shield your equipment from damage. When you install a guard, you get protection from debris that could otherwise enter the fan. This keeps dust, screws, or other small objects from jamming the blades or causing breakdowns. Fan grills also help airflow stay smooth, so your system runs better and lasts longer.

You’ll notice that Linkwell’s fan guards work with other safety features. They keep foreign objects out and help the fan run without blockages. This teamwork means your cooling system stays reliable and efficient. You spend less time on repairs and more time getting work done.

Supporting Compliance

You need to meet strict rules for cooling system safety in your workplace. Fan guards help you do that. According to OSHA, all fans within 7 feet of the floor must have guards that block access to the blades. The openings can’t be wider than half an inch. This rule keeps everyone safe and helps you avoid fines.

Fan guards also support other safety standards. Here’s how they help your cooling system meet regulations:

- Proper ventilation keeps harmful dust and fumes away from your workspace.

- Fan guards maintain airflow, so exhaust systems work as they should.

- Good design ensures enough air moves to carry away dangerous materials.

Linkwell always designs fan guards to meet or exceed these standards. You can trust their products to keep your team safe and your equipment running smoothly.

Benefits for Performance and Reliability

Enhanced Efficiency

You want your cooling system to work at its best every day. Fan guards help you reach higher efficiency by keeping airflow smooth and steady. When you use Linkwell’s fan filter units or axial fans, you get designs that support strong airflow and block dust. EC fans from Linkwell use up to 70% less power than older AC fans. That means you save energy and money while your system stays cool. You also get easy installation, so you spend less time setting up and more time enjoying optimized performance.

| Fan Type | Typical Lifespan |

|---|---|

| AC Fan | 5–8 years |

| EC Fan | 10–15 years |

You can see that EC fans last longer and use less energy. This boosts your system’s efficiency and helps you meet your goals for reliable cooling.

Lower Maintenance

Nobody likes spending hours fixing equipment. Fan guards make your life easier by cutting down on maintenance needs. Air filters in fan guards stop dust and particles from building up inside your system. You get fewer breakdowns and less downtime. Here’s how fan guards help you keep things running:

- Air filters block dirt, so fans stay clean and work better.

- You spend less on repairs because parts last longer.

- Your production process runs smoother with fewer interruptions.

Linkwell’s products are built for durability, so you don’t have to worry about constant repairs. You get more time to focus on your work and less time fixing problems.

Extended Equipment Life

You want your cooling system to last as long as possible. Fan guards protect your equipment from damage and help it run longer. Fan grills keep debris and foreign objects out, which means fewer broken parts and lower costs. Over time, you save money because your system stays efficient and reliable. The key benefits of fan guards include safety, protection, and cost savings.

- Fan guards prevent accidents and keep your team safe.

- They extend the life of your cooling system by blocking harmful debris.

- You enjoy long-term savings and better system efficiency.

When you choose Linkwell, you invest in products that deliver strong protection and lasting value. Your cooling system works better, needs less maintenance, and stays reliable for years.

You want your cooling system to stay safe and reliable. Fan guards play a key role in protecting you and your equipment. Take a look at the main benefits:

| Key Takeaway | Description |

|---|---|

| Safety Enhancement | Guards prevent accidents and keep foreign objects out of the fan. |

| Material Benefits | Metal guards last longer and work well in tough environments. |

| Performance Improvement | Guards help airflow, reduce noise, and extend fan life. |

Choose a quality fan guard from Linkwell. Make sure you check and clean your guards often. You keep your system running smoothly and protect everyone around it.

FAQ

What does a fan guard actually do?

A fan guard keeps your hands, tools, and debris away from spinning blades. You stay safe, and your equipment runs better. It’s a simple way to protect both people and machines.

How often should I clean or check my fan guard?

You should check your fan guard every month. Clean off dust and debris when you see buildup. Regular checks help your cooling system work smoothly and last longer.

Can I use any fan guard for my cooling system?

No, you need to match the guard to your fan type and environment. Steel wire guards work best for heavy-duty jobs. Plastic guards suit lighter tasks. Linkwell offers options for every need.

Do fan guards affect airflow or noise?

Fan guards can change airflow and noise a little. Wire guards keep airflow strong and noise low. Mesh or plastic guards may quiet things down more. Choose the right guard for your space.