You need to get the heating calculation right if you want to protect your sensitive electronics. The basic approach for How to calculate watts and heat of enclosure heating uses the formula: Watts = surface area × temperature difference × heat transfer coefficient. This method helps you size the heating element properly, whether you work with air, water, or metal enclosures. Linkwell’s Enclosure Heater uses this principle to deliver reliable heating in tough industrial environments. You can trust this heating element to keep your systems safe and dry.

Key Takeaways

- Use the formula Watts = Surface Area × Temperature Difference × Heat Transfer Coefficient to find the heating power needed for your enclosure.

- Measure your enclosure’s size and calculate its surface area to understand how much heat escapes.

- Consider insulation and internal heat sources to reduce the heating power required and save energy.

- Choose a heater with wattage equal to or higher than your calculated need to protect electronics and prevent condensation.

- Use built-in thermostats and IP65-rated heaters for safe, efficient heating in tough environments.

How to calculate watts and heat of enclosure heating

Key formula and variables

You want to know how to calculate watts and heat of enclosure heating for your project. The process starts with a simple formula that experts and manufacturers use:

Wattage = Surface Area × Temperature Difference × Heat Transfer Coefficient

This formula helps you figure out the heating power in watts needed to keep your enclosure at the right temperature. You measure the surface area of the enclosure, decide how much you want to raise the temperature, and use the heat transfer coefficient based on your insulation and enclosure material.

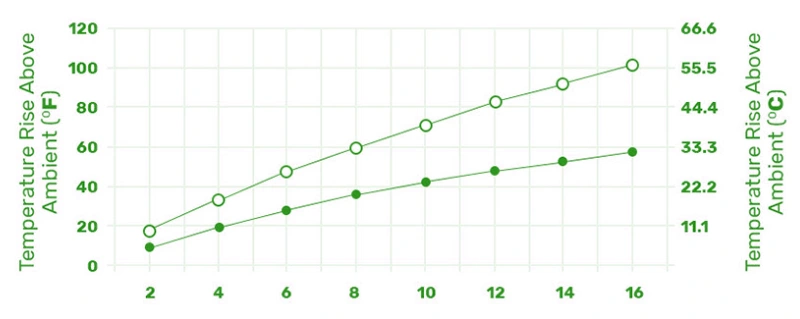

Industry standards recommend using wattage tables to match your enclosure’s surface area and desired temperature rise with the right wattage. Here’s a quick look at how insulation affects your heating needs:

| Temperature Rise (°F) | Wattage for Insulated Enclosure (W) | Wattage for Uninsulated Enclosure (W) |

|---|---|---|

| 20 | 10–50 | 30–135 |

| 60 | 60–290 | 245–1210 |

| 140 | 205–1120 | 845–4690 |

You see that insulated enclosures need much less wattage. If you add insulation, you save energy and reduce your total heat load.

When you calculate the wattage, you need to look at several variables:

- The surface area of the enclosure controls how much heat escapes.

- The temperature difference between inside and outside drives the heat load.

- Insulation (R-value and U-value) changes how much heating you need.

- Internal heat sources like electronics, lights, and people add to the total heat load.

- The shape, size, and position of heat sources affect how heat moves inside.

If you want to get technical, you can use dimensionless numbers like Rayleigh or Grashof to model convection. Most people just use the basic formula and tables.

Calculate wattage

Let’s walk through how to calculate watts and heat of enclosure heating step by step. First, measure your enclosure’s length, width, and height. Multiply these to get the surface area. Next, decide how much you want to raise the temperature inside. Subtract the lowest expected outside temperature from your target internal temperature. This gives you the temperature difference.

Now, check your insulation. If your enclosure has good insulation, you need less heating. If it’s uninsulated, you need more. Use the heat transfer coefficient for your material and insulation level.

Don’t forget about internal heat sources. Add up the power ratings of all electronics, lights, and other equipment inside. This total heat load reduces the amount of extra heating you need. Here’s a simple way to account for it:

- List all internal components and their power ratings.

- Add up the wattage for each item.

- Subtract this total heat load from your calculated heating requirement.

If you want to save time, try online calculators like the Enclosure Temperature Management Calculator or the STEGO heating and cooling tool. These tools ask for your enclosure size, insulation, and temperature settings. They quickly calculate the wattage and recommend products that fit your needs. Manufacturer tools also help you avoid mistakes and get accurate results.

You can always reach out to Linkwell for expert advice or use their enclosure heater selection guide. Their heaters come in a wide range of wattage options, so you can match your calculated needs with the right product.

Tip: Always double-check your numbers and consider the environment. Outdoor enclosures need more heating than indoor ones. If you have solar exposure or high humidity, adjust your calculations.

By following these steps, you learn how to calculate watts and heat of enclosure heating for any project. You protect your electronics, save energy, and make sure your system runs smoothly.

Step-by-step process

Measure enclosure size

Start by measuring your enclosure’s height, width, and depth. You want to find the total surface area because it determines how much heat escapes. Use this formula:

Total Surface Area = 2(H × W) + 2(H × D) + 2(W × D)

Measure in feet for easy calculation. If your enclosure sits against a wall, subtract that side’s area since it doesn’t lose heat. The surface area helps you estimate the heat load and select the right heating solution.

Determine temperature difference

Next, figure out the temperature difference between the inside and outside of your enclosure. Subtract the lowest expected outdoor temperature from your target internal temperature. This difference drives the heating requirement. A bigger gap means more heat escapes, so you need higher wattage to keep things warm. For example, if you want 68°F inside and expect 28°F outside, your temperature difference is 40°F. The greater the difference, the more heating you need.

Assess insulation and environment

Check your insulation. Good insulation reduces heat loss and lowers your heating needs. Materials like mineral wool, ceramic fiber, or silica aerogel work well in industrial settings. Here’s a quick look at common insulation options:

| Insulation Material | Effectiveness | Typical Use |

|---|---|---|

| Mineral Wool | High | HVAC, engine rooms |

| Ceramic Fibre | Very High | Kilns, boilers |

| Silica Aerogel | Exceptional | Aerospace, cryogenics |

Think about your environment too. High humidity increases condensation risk, so you may need extra heating to keep the inside above the dew point. Airflow also matters. If your enclosure has fans or vents, warm air mixes with cooler air, which can change your heating needs.

Apply the formula

Now, put it all together. Here’s a simple process:

- Add up the wattage of all active components inside your enclosure. This is your internal heat load.

- Calculate the surface area using your measurements.

- Find the temperature difference.

- Use the formula:

Required Wattage = Surface Area × Temperature Difference × Heat Transfer Coefficient - Subtract the internal heat load from your calculated wattage. This gives you the total heat load your heater must supply.

Linkwell’s Enclosure Heater makes this easy. You can choose a model that matches your total heat load, with options for thermostat control and IP65 protection. This ensures reliable heating, prevents condensation, and keeps your electronics safe.

Tip: Use online calculators or Linkwell’s selection guide for quick results. Always double-check your numbers and consider insulation and humidity for best performance.

Example calculation

Sample data

Let’s look at a real-world scenario. You want to keep your industrial enclosure warm during cold months. You need to know how much heating is required. Here’s a sample dataset that helps you get started:

| Dataset Release | Building Stock Represented | Weather Data | Relevant Measure Packages |

|---|---|---|---|

| 2024.1 Release | U.S. residential sector circa 2018 | TMY3 weather data | Envelope (including enclosure heating), Heating and cooling, Water heating, Lighting, Appliances, Pools and spas, Combinations |

| 2022.1 Release | N/A (focus on measure packages) | N/A | Includes ‘Basic enclosure’ and ‘Enhanced enclosure’ packages among others relevant to enclosure heating calculations |

You can use these datasets to estimate heating needs for different enclosure types. They include weather data and measure packages that help you model your enclosure’s environment and heating requirements.

Calculation walkthrough

Now, let’s walk through the steps. Imagine you have a steel enclosure with these dimensions: height 2 ft, width 3 ft, depth 1 ft. You want to keep the inside at 68°F, while the outside drops to 28°F. You use mineral wool insulation.

- Calculate surface area

You measure each side and add them up:Surface Area = 2(2×3) + 2(2×1) + 2(3×1) = 12 + 4 + 6 = 22 ft² - Find temperature difference

Your target is 68°F inside, 28°F outside.Temperature Difference = 68°F - 28°F = 40°F - Estimate heat transfer coefficient

Mineral wool insulation gives you a lower coefficient. You use 0.08 BTU/hr·ft²·°F for insulated steel. - Apply the heating formula

Required Heating = Surface Area × Temperature Difference × Heat Transfer Coefficient Required Heating = 22 × 40 × 0.08 = 70.4 BTU/hrYou convert BTU/hr to watts (1 watt = 3.41 BTU/hr):Required Heating = 70.4 / 3.41 ≈ 21 watts - Adjust for real-world conditions

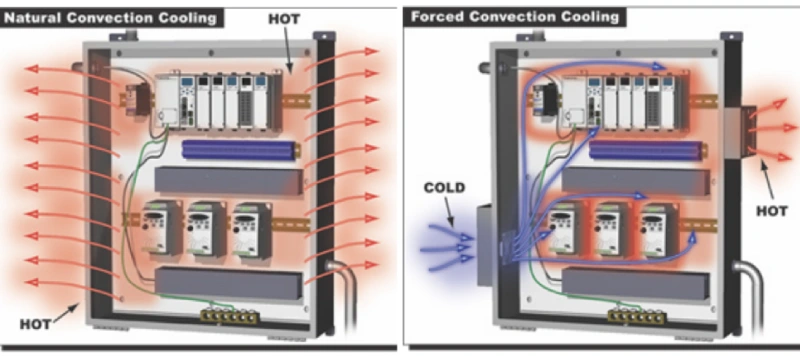

In practice, heating calculations can underestimate internal temperatures. You may notice the upper part of your enclosure gets warmer. Internal fans help spread heat, but sealed enclosures limit air movement. You might need to increase heating slightly or use a heater with a built-in fan.

- Typical heating calculations use the heat transfer equation, but actual results vary.

- Temperature gradients inside the enclosure affect heating performance.

- Fans or forced air panels can improve heating distribution.

- Simple formulas may underestimate heating needs in sealed enclosures.

Tip: Always round up your heating requirement and choose a heater with a thermostat. This keeps your electronics safe and prevents condensation.

Product selection with Linkwell Enclosure Heater

Choosing the right model

You want to make sure your enclosure stays safe and dry, so picking the right Linkwell Enclosure Heater matters. Start by calculating your required wattage using the steps from earlier. Once you know your heating needs, follow these steps to select the best model:

- Match your calculated wattage to a Linkwell Enclosure Heater that meets or slightly exceeds your requirement. This ensures the heating element can reach your target temperature quickly and reliably.

- Think about your enclosure’s size, insulation, and how fast you need it to warm up. If you need rapid heating, choose a model with a higher wattage heating element.

- Check the available voltage options. Linkwell offers heaters for 12V, 24V, 120V, and 230V systems.

- Look for features that fit your environment, like IP65-rated models for outdoor or dusty locations.

Tip: Always select a heater with a wattage rating equal to or greater than your calculated need. This helps you avoid underheating and keeps your electronics protected.

Here’s a quick checklist to help you compare:

| Feature | Why It Matters |

|---|---|

| Wattage | Matches your heating requirement |

| IP65 Rating | Protects against dust and water |

| Thermostat Integration | Maintains stable internal temperature |

| Mounting Options | Fits your enclosure setup |

Safety margins and controls

When you choose a Linkwell Enclosure Heater, you get more than just a heating element. These heaters come with built-in thermostat controls that cycle the heating on and off, saving energy and preventing overheating. The self-regulating design means the heating element only runs when needed, which keeps your operating costs down.

- IP65-rated enclosures keep out dust and water, so your heater works even in harsh conditions.

- Built-in overheat protection and thermal cut-offs add another layer of safety.

- Compliance with CE, UL, and RoHS standards means you can trust the heater in any industrial setting.

You should schedule maintenance checks at least once a year, or even twice for critical applications. Regular inspections help you spot loose connections, buildup on the heating element, or any signs of water ingress. This keeps your heating system running smoothly and extends its life.

Note: Integrated controls not only boost energy efficiency but also protect your equipment from condensation and frost. You get peace of mind knowing your enclosure is always at the right temperature.

You’ve learned how to calculate enclosure heating wattage step by step. When you use Linkwell Enclosure Heaters, you protect sensitive electronics from moisture, freezing, and condensation. These heating solutions work in harsh environments and support industrial automation. To avoid common mistakes, always double-check your heating calculations, consider ambient temperature, and plan for maintenance. If you want reliable heating, consult Linkwell for customized solutions. Accurate heating keeps your equipment safe and extends its lifespan.

- Common mistakes to avoid:

- Failing to account for total heating load

- Ignoring ambient temperature

- Neglecting maintenance

Tip: Always review your heating setup and environmental factors before finalizing your choice.

FAQ

How do I know if my enclosure needs heating?

If you see condensation, frost, or temperature swings inside your enclosure, you probably need heating. Sensitive electronics work best in stable conditions. Heating helps prevent moisture and keeps your equipment safe.

Can I use one heater for multiple enclosures?

You should use a separate heater for each enclosure. Each space has its own heat loss and airflow. One heater may not provide even heating or enough protection for all your equipment.

What is the best way to control enclosure heating?

A built-in thermostat works best. It turns the heater on and off as needed. This keeps the temperature steady and saves energy. You can also use a hygrostat if you want to control humidity.

How do I install a Linkwell Enclosure Heater?

You can mount the heater on a DIN rail or screw it to the panel. Follow the wiring diagram in the manual. Always turn off power before installation. If you are unsure, ask a qualified electrician for help.

Will heating prevent condensation in my enclosure?

Yes! Heating keeps the internal temperature above the dew point. This stops moisture from forming on surfaces. Your electronics stay dry and last longer.

Conclusion

Accurate heating calculation is essential to protect sensitive electronics in enclosures. By applying the formula Watts = Surface Area × Temperature Difference × Heat Transfer Coefficient, you can size heaters correctly, reduce condensation, and ensure long-term equipment reliability. Linkwell Enclosure Heaters provide efficient, IP65-rated solutions tailored to diverse industrial environments. Proper calculation minimizes energy waste, prevents overheating, and keeps your systems dry, stable, and safe throughout changing temperatures and harsh outdoor conditions.