When you want wiring that’s both simple and secure, Electrical Enclosure Din Rail delivers every time. You get peace of mind knowing Linkwell manufactures each rail with certified quality, robust construction, and custom sizing, so your project fits perfectly—no matter the scale. As a direct factory, Linkwell welcomes small orders and provides fast, flexible support. Take a look at what sets Linkwell apart:

| Feature | What You Get |

|---|---|

| Certified Quality | ISO 9001, CE, RoHS, IP-rated protection |

| Customization Options | Flexible sizes, materials, and finishes |

| Dedicated Support | 24/7 guidance and reliable after-sales help |

Key Takeaways

- Electrical Enclosure Din Rails simplify wiring by allowing quick installation without tools. This saves time and effort on your projects.

- Linkwell offers certified quality DIN rails that meet international standards, ensuring safety and reliability for your electrical systems.

- Custom sizing and flexible options from Linkwell mean you can get the exact DIN rail you need, even for small orders.

- Organized wiring with DIN rails enhances safety and makes troubleshooting easier, reducing the risk of mistakes and equipment failure.

- Linkwell provides 24/7 technical support, helping you with installation and ensuring your projects run smoothly.

Electrical Enclosure Din Rail Overview

What Is a DIN Rail?

If you’ve ever opened an electrical panel, you’ve probably seen a long metal strip holding all the devices in place. That’s a DIN rail. It acts like a backbone for your control cabinet, letting you snap in circuit breakers, relays, and terminal blocks quickly and securely. You don’t need screws or complicated tools. Just click your components onto the rail, and you’re ready to go.

There are several types of DIN rails, each with its own job:

- Top Hat Rails (TS35) – The most common, 35mm wide, perfect for most modern devices.

- Mini Top Hat Rails (TS15) – Only 15mm wide, great for tight spaces and smaller components.

- C Rails – 32mm wide, built for heavier equipment.

- G Rails (TS32) – Also 32mm, designed for extra support with heavy-duty parts.

Here’s a quick look at how they compare:

| Type of DIN Rail | Width (mm) | Depth (mm) | Main Use |

|---|---|---|---|

| Top Hat (TS35) | 35 | 7.5 / 15 | Versatile, fits most components |

| Mini Top Hat (TS15) | 15 | 5.5 | Compact, for small devices |

| C Rail | 32 | N/A | Supports heavier equipment |

| G Rail (TS32) | 32 | N/A | Heavy-duty support |

You’ll find Electrical Enclosure Din Rail systems in everything from factories to solar power stations. As automation and smart technology grow, these rails become even more important for keeping things organized and safe.

Linkwell’s DIN Rail Features

When you choose Linkwell, you get more than just a piece of metal. You get a product built for global standards and real-world demands. Linkwell manufactures every Electrical Enclosure Din Rail to meet strict certifications, so you know your project is in good hands.

| Certification | What It Means for You |

|---|---|

| IEC 60715 | Fits with major brands and equipment worldwide |

| UL | Meets top safety and quality standards |

| CE | Recognized for compliance and reliability |

Linkwell uses corrosion-resistant materials, so your rails last even in tough environments. You can pick from different profiles and sizes, and even request custom lengths or private labeling. Need a small order for a special project? Linkwell’s factory can handle it fast, with direct support every step of the way.

Tip: As industries move toward automation and smarter systems, having a reliable Electrical Enclosure Din Rail setup helps you stay ahead. Linkwell’s rails keep your wiring neat, safe, and ready for whatever comes next.

Simplifying Wiring with DIN Rails

Fast and Flexible Installation

You want your wiring project to move quickly. Electrical Enclosure Din Rail makes that possible. You can snap components into place without taking apart the whole cabinet. This saves you time and effort. Linkwell’s rails fit tight spaces, so you don’t waste room inside your enclosure. You get a smooth installation, even if you need to make changes or add new devices later.

Here’s how DIN rails speed up your work:

| Benefit | Explanation |

|---|---|

| Smooth installation | New components slide or snap into position without dismantling the entire structure. |

| Space optimization | DIN rails fit tight spaces, allowing for efficient wiring connections. |

| Cost-effectiveness | Less effort and space usage mean savings and less downtime, so you manage projects better. |

Linkwell manufactures DIN rails to international standards, so you can use them in many types of cabinets. You get custom sizes and profiles, which means you can order exactly what you need—even for small projects. As a direct factory, Linkwell delivers fast and supports you every step of the way.

Organized and Safe Wiring

Messy wiring can lead to mistakes and safety risks. Electrical Enclosure Din Rail helps you keep everything neat and secure. You group terminals by function and voltage level. Separator plates keep different voltage systems apart. You maintain clearances for safe operation. High-current blocks stay away from sensitive circuits. You leave space for wire bending and routing.

Here’s what organized wiring looks like with DIN rails:

| Benefit | Description |

|---|---|

| Enhanced Safety | Safe interface between components and wiring sections prevents accidental contact. |

| Efficient use of panel space | Maximizes available space in electrical enclosures. |

| Enhanced organization | Systematic wiring makes everything accessible and manageable. |

- Group terminals by function and voltage level.

- Use separator plates between different voltage systems.

- Maintain minimum clearances for safe operation.

- Position high-current blocks to minimize thermal impact on sensitive circuits.

- Allow adequate space for wire bending and routing.

Linkwell’s rails use corrosion-resistant materials, so your wiring stays safe in tough environments. You get a reliable setup that meets global standards. You can even request private labeling or custom packaging for your business.

Tip: Neat wiring not only looks professional, but also makes troubleshooting and upgrades much easier.

Modular Design Benefits

You want flexibility for future changes. DIN rail systems give you that. You can add, remove, or reposition components without redoing the whole panel. The modular design lets you snap on replacements quickly. You spend less time on maintenance and upgrades. You can expand your system as your needs grow.

With Linkwell, you get rails that support custom assembly and accessories like insulated bridges and labeling clips. You can choose housing widths and conductor connections that fit your project. Optional laser labeling makes identification easy.

The modular setup means you organize and label components for fast troubleshooting. You maximize space and keep your enclosure efficient. If you need to upgrade, you swap out parts with minimal downtime. Linkwell’s factory can handle custom requests and small orders, so you get exactly what you need for any project size.

Note: Modular DIN rail systems help you adapt to new technology and changing requirements without hassle.

Safety Advantages of DIN Rails

Secure Mounting and Vibration Resistance

You want your electrical components to stay put, even when things get rough. DIN rails give you that confidence. When you use a solid rail, you get maximum rigidity. Slotted rails offer flexibility and make wiring easier, but still hold everything tight. If you work in an environment with lots of movement or vibration, TS32 DIN rails step up with extra strength. You don’t have to worry about loose connections or shifting parts.

Take a look at how different rail types and certifications help you:

| Evidence Type | Description |

|---|---|

| IEC Certification | Ensures safety, reliability, and performance in industrial applications. |

| TS35 DIN Rail | Built for high-strength demands, handles dynamic forces, stays durable. |

| Solid vs. Slotted | Solid rails resist vibration, slotted rails reduce weight for easy wiring. |

Linkwell manufactures every rail to meet these standards. You get rails that hold up in factories, transport systems, and anywhere vibration is a concern. As a direct factory, Linkwell can customize rails for your specific needs—even for small orders.

Tip: If your project faces heavy vibration, ask Linkwell about high-strength DIN rail options. You’ll get the right fit for your environment.

Compliance with International Standards

You want products that meet global safety rules. Linkwell’s DIN rails check every box. Each rail follows IEC 60715, so you know it fits with major brands and equipment worldwide. You see CE and RoHS marks, which means your rails are safe for people and the planet. UL certification gives you peace of mind for projects in the U.S.

Here’s a quick look at the standards Linkwell meets:

| Standard | Description |

|---|---|

| IEC 60715 | International standard for DIN rails |

| CE | Conforms to health, safety, and environmental protection standards in Europe |

| RoHS | Free from hazardous materials, safe for the environment |

| UL | Certified for safety and performance in the U.S. |

You don’t have to guess if your rails are up to code. Linkwell’s factory controls every step, so you get consistent quality. You can order in bulk or request small quantities for special projects. Linkwell supports you with technical advice and fast delivery.

Note: Choosing certified rails means you avoid compliance headaches and keep your project running smoothly.

Enhanced Protection in Industrial Environments

Industrial settings can be tough on electrical systems. You need protection against heat, vibration, and electrical faults. Electrical Enclosure Din Rail helps you keep everything safe and reliable. Terminal blocks mounted on DIN rails create secure connections. Sturdy construction prevents loose wires and reduces the risk of equipment failure. Reliable rails help stop overheating and electrical faults before they start.

Here’s how DIN rails protect your setup:

- Terminal blocks ensure secure, reliable connections inside control cabinets.

- Strong rails minimize loose connections, which can cause malfunctions.

- Reliable mounting helps prevent overheating and electrical failures.

You can prevent common problems by choosing quality rails and following best practices. Linkwell recommends conduction detection tests for terminal blocks and targeted reliability testing. These steps help you catch issues early and keep your system safe.

| Preventive Measure | Description |

|---|---|

| Conduction Detection | Test each terminal block to prevent contact failure. |

| Reliability Testing | Run targeted tests to ensure every rail meets technical requirements. |

Linkwell’s rails work in harsh environments, from energy plants to automated factories. You get products that last, backed by a manufacturer who supports you every step of the way. Need a custom solution or a small batch? Linkwell delivers quickly and helps you succeed.

Alert: Regular testing and quality rails keep your electrical system safe, even in the toughest conditions.

How to Use Linkwell Din Rail

Choosing the Right DIN Rail

Picking the right DIN rail for your project makes everything easier. Start by looking at your enclosure size and the type of devices you want to mount. Top Hat rails work for most control panels, while C Rails or G Rails handle heavier equipment. Think about the environment, too. If you need corrosion resistance, go for stainless steel or aluminum. Linkwell offers a range of profiles and materials, so you always find the perfect fit.

Need something special? Linkwell supports custom sizes, connection types, and even private labeling. Check out how you can tailor your order:

| Customization Options | Benefits |

|---|---|

| Size | Fits your exact enclosure and device needs |

| Connection Type | Works with different systems |

| Voltage Range | Handles your specific electrical requirements |

| Custom Labeling | Makes maintenance and identification simple |

| Colors/Branding | Matches your company’s look and boosts your brand |

Tip: You can order just what you need—even for small projects. Linkwell’s factory handles small batches with the same care as big orders.

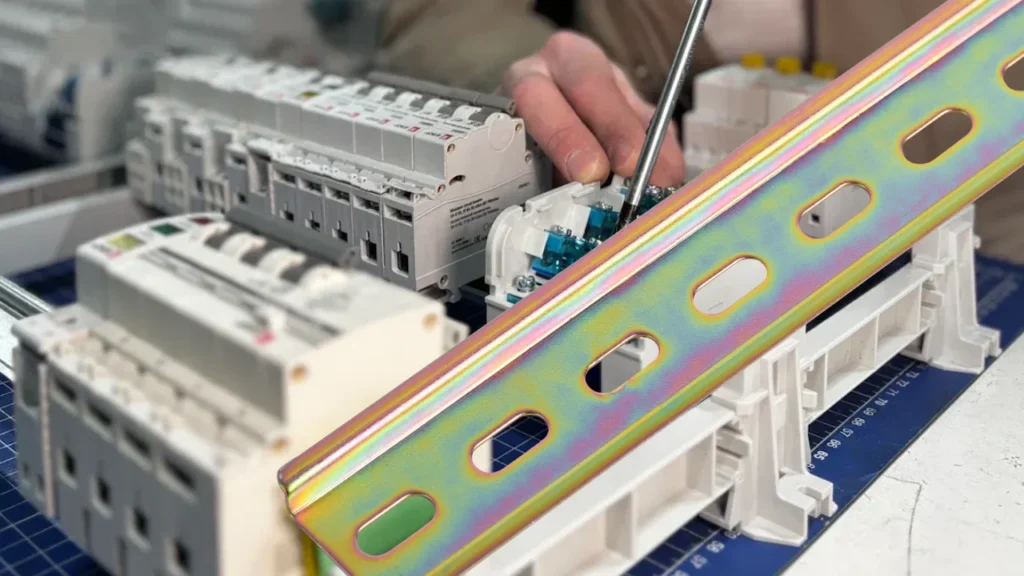

Installation Steps

You don’t need to be an expert to install a DIN rail. Just follow these steps for a smooth setup:

- Choose the best spot inside your cabinet or enclosure.

- Mount the DIN rail securely—usually a 35mm rail fits most needs.

- Attach any DIN clips or brackets to your devices.

- Snap your devices onto the rail and make sure they’re locked in place.

- Connect the power supply.

- Hook up data and communication cables.

- Ground the rail to prevent electrical issues.

- Check that there’s enough airflow for cooling.

- Power on and test your setup.

- Double-check all connections and keep an eye out for any issues.

Note: Linkwell’s support team is ready to help if you have questions during installation or need advice on custom setups.

Best Practices for Maintenance

Keeping your Electrical Enclosure Din Rail system in top shape is easy. Inspect connections regularly and look for signs of wear or corrosion. Clean the rails and terminals to prevent dust buildup. Use custom labels to make future maintenance faster. If you ever need replacements or upgrades, Linkwell can supply matching parts—even for small orders.

- Schedule routine checks for loose connections.

- Replace worn or damaged components right away.

- Keep your wiring organized for easy troubleshooting.

Callout: With Linkwell, you get ongoing support, fast delivery, and flexible solutions—no matter the size of your order.

Applications and Custom Solutions

Industrial and Automation Uses

You see Electrical Enclosure Din Rail in action across many industries. These rails keep your wiring organized and safe in factories, energy plants, and smart buildings. You can mount controllers, power supplies, I/O modules, and other devices with ease. This setup works well for control panels, machinery, and junction boxes. You get protection from dust, moisture, and vibration, which means your system stays reliable even in tough environments.

Here’s a quick look at where DIN rails shine:

| Application Type | Description |

|---|---|

| DIN Rail Junction Box | Compact, organized solution for electrical connections in automation systems. |

| Control Panels and Machinery | Streamlines wiring, boosts safety, and makes maintenance simple. |

| Protection from Environmental Factors | Shields connections from dust, moisture, and mechanical stress for better reliability. |

You also benefit from quick installation and space-saving designs. Snap-on mounting lets you finish wiring up to 70% faster than old methods. You don’t need to worry about loose connections, even when machines vibrate or temperatures change.

OEM/ODM and Private Label Options

If you want to stand out in the market, Linkwell’s OEM and ODM services give you a real edge. You can customize every detail—size, finish, cooling capacity, and even packaging. Linkwell’s advanced manufacturing system ensures quality and traceability for every order. You get your products fast, usually within 2-3 weeks, while other suppliers may take much longer.

Here’s what you gain with Linkwell’s flexible options:

- Cost-effective solutions for startups and established brands.

- Fast time-to-market, so you launch products quickly.

- Full customization for electrical specs, design, and certifications.

- Private label branding and packaging to boost your company’s image.

Tip: You can tailor your Electrical Enclosure Din Rail order to match your brand and technical needs, making your business more competitive.

Linkwell’s Support for Small Orders

You don’t need to place a huge order to get Linkwell’s best service. The factory welcomes small batches and custom requests. You get the same attention to detail and fast delivery, no matter the project size. Linkwell’s team helps you choose the right rail, offers technical support, and even provides free samples or drawings before you commit.

- Flexible minimum order quantities for any project.

- Direct factory support and quick response times.

- Custom packaging and labeling, even for small runs.

Note: Linkwell’s commitment to small orders means you can test new ideas, handle urgent jobs, or serve niche markets without hassle.

Conclusion

You want wiring that’s easy, safe, and built to last. Electrical Enclosure Din Rail from Linkwell gives you all that and more. You get a system that makes installation fast, keeps your wiring neat, and protects your equipment in any environment. Linkwell stands out as a trusted factory, ready to handle both big projects and small orders with the same care.

When you choose Linkwell, you tap into decades of experience and a team that supports you every step of the way. You can customize your rails, pick the right size, and even add your own branding. Need a quick turnaround? Linkwell’s rapid delivery keeps your project on track. You never have to worry about quality—every rail meets strict international standards.

Tip: If you have a unique project or need just a few rails, Linkwell welcomes your small order. You get the same expert support and fast service as the largest clients.

Here’s what you gain with Linkwell:

- Certified products that meet IEC, CE, and UL standards

- Custom solutions for any enclosure or device

- Flexible order sizes, from one piece to thousands

- 24/7 technical support and after-sales help

Ready to make your wiring project easier and safer? Reach out to Linkwell today. You can get a quote, request samples, or talk to an expert about your needs. Visit Linkwell’s website or contact the team directly. Your next project deserves the best—choose Linkwell for reliable, certified, and flexible solutions.

You get wiring that’s easy, safe, and built for your needs with Linkwell’s DIN rails. Here’s why you’ll love working with Linkwell:

- IP-rated enclosures protect against dust and water.

- UL, CE, and RoHS certifications mean top safety.

- Ventilation and thermal management keep systems cool.

- Custom solutions fit any project, even small orders.

- Fast delivery and strong technical support reduce downtime.

| What You Gain | Why It Matters |

|---|---|

| Certified products | Reliable, safe wiring for every environment |

| One-year warranty | Peace of mind for your investment |

| Lifetime support | Help with installation and troubleshooting |

| Flexible order sizes | Perfect for big jobs or small batches |

Ready to upgrade your wiring? Reach out to Linkwell for expert help and tailored solutions.

FAQ

What is an Electrical Enclosure DIN Rail used for?

You use a DIN rail to mount devices like circuit breakers, relays, and terminal blocks inside electrical panels. It keeps your wiring organized and makes upgrades or repairs quick and easy.

Can I order just a few DIN rails from Linkwell?

Yes! You can place small orders directly with Linkwell. The factory welcomes projects of any size and gives you the same fast support and quality, whether you need one rail or a thousand.

How do I choose the right DIN rail for my project?

Start by checking your enclosure size and the devices you want to mount. Linkwell offers Top Hat, C, and G rails in different materials and sizes. You can ask for custom options to fit your needs.

Are Linkwell DIN rails certified for international use?

Absolutely. Linkwell’s DIN rails meet IEC 60715, CE, and UL standards. You can use them worldwide with confidence. The factory controls every step to ensure top quality.

Does Linkwell offer technical support for installation?

Yes, you get 24/7 technical support from Linkwell. The team helps you with installation, custom requests, and troubleshooting. You can even request free samples or drawings before you order.