Custom Industrial Control Transformer Manufacturer in China

An Industrial Control Transformer provides safe, stable voltage for control circuits in cabinets and telecom systems. At Linkwellelectrics, we manufacture and supply high-quality transformers, ensuring durability and efficiency for global industrial applications. Contact us today for trusted solutions.

Linkwell Electrics - Your Trusted Industrial Control Transformer Manufacturer from China

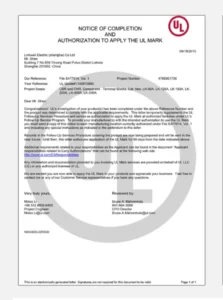

High quality with UL, CE, and ISO9001 certifications.

Strong durability with low maintenance requirements.

Energy-efficient design reduces long-term operational costs.

Custom options available for industrial-specific needs.

By choosing us as your Industrial Control Transformer supplier, you benefit from superior product quality, fast delivery schedules, and reliable market support.

We help wholesalers and distributors build stronger business performance with consistent transformer supply and expert technical service.

Global Partnership

Industrial Control Transformer Type

We offer custom UL Electrical Enclosures in various sizes, IP ratings, materials (steel, aluminum, plastic), and surface coatings. Custom production reduces costs, meets regional standards, and supports market expansion. We guarantee stable quality, timely delivery, and competitive pricing

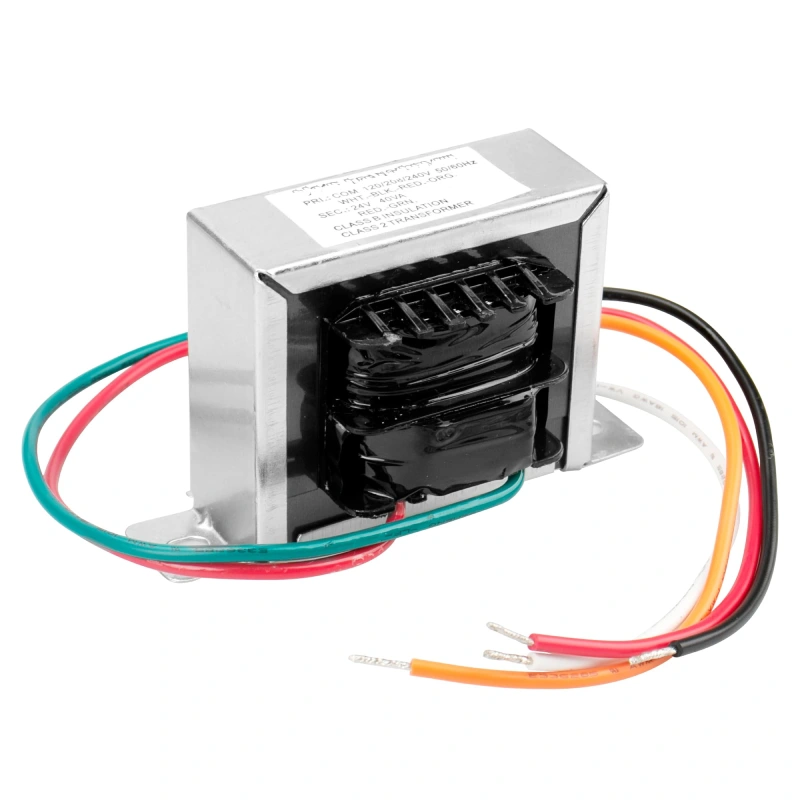

Enclosed Control Transformers

Description: Housed in a protective enclosure (e.g., NEMA Type 1) to shield against dust, moisture, and physical damage, making them suitable for harsh industrial environments

Key Features: Enhanced safety, corrosion resistance, and reduced noise. Often used in outdoor or dirty settings

Applications: Industrial control panels, machinery exposed to contaminants

Open Core & Coil Transformers

Description: Unencapsulated design without an enclosure, typically used where space constraints exist and environmental hazards are minimal.

Key Features: Compact, cost-effective, and flexible for custom mounting. Often epoxy-encapsulated to prevent corrosion.

Applications: HVAC systems, control cabinets, and conveyor systems

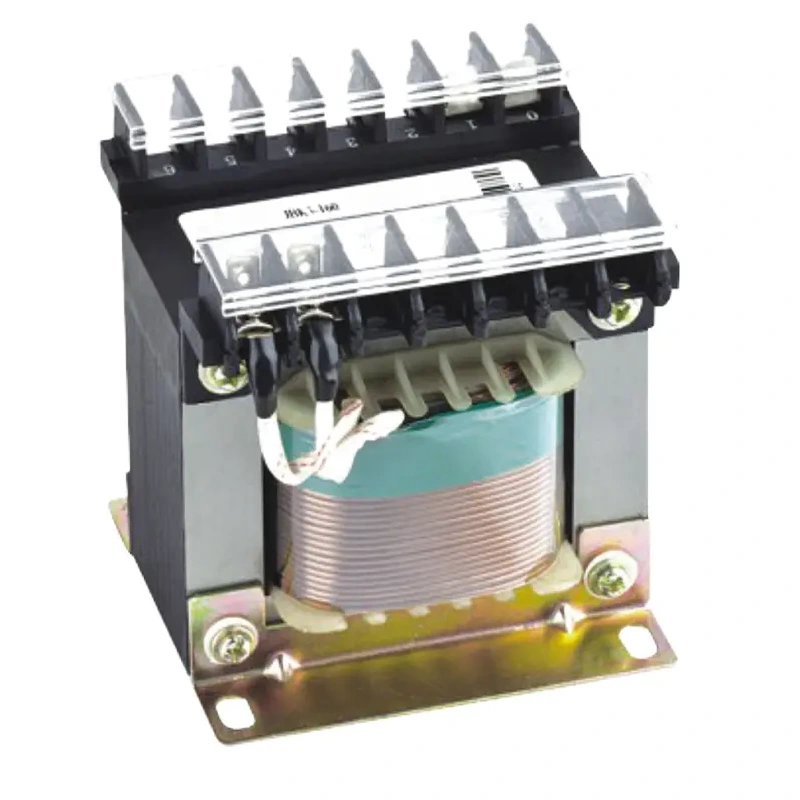

Machine Tool Control Transformers

Description: Specifically designed for machine tools, with high inrush current tolerance to handle the startup demands of electromagnetic devices (e.g., solenoids and relays).

Key Features: High voltage stability during inrush (up to 10x normal current), copper windings, and compliance with NEMA/UL standards.

Applications: CNC machines, lathes, and industrial automation equipment.

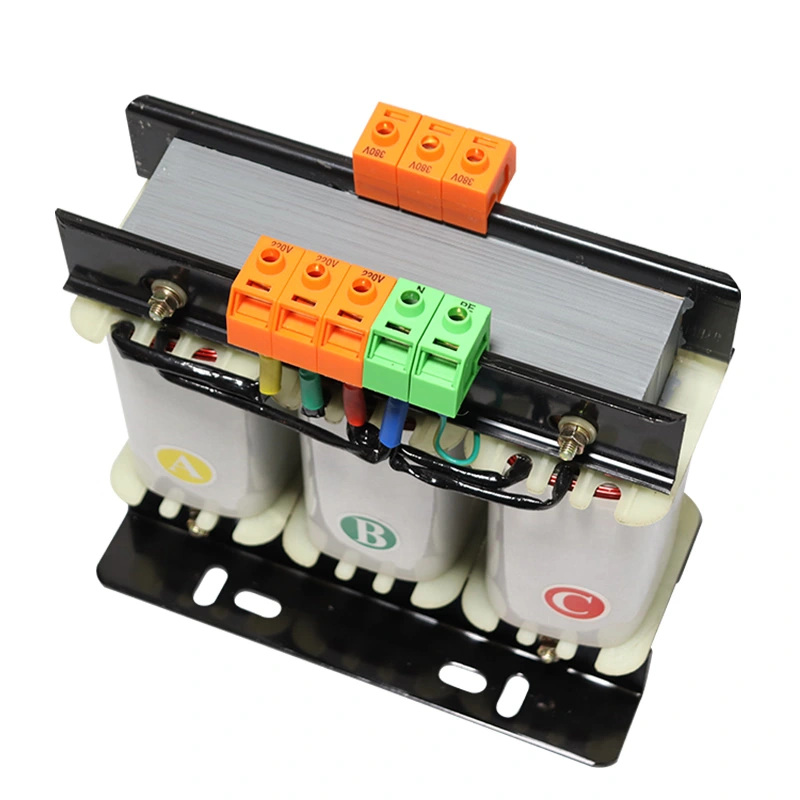

Three-Phase Control Transformers

Description: Used in three-phase power systems to step down higher voltages (e.g., 480V or 600V) to lower control voltages (e.g., 24V or 120V) for balanced power distribution.

Key Features: Handles higher power loads (up to 7.5 kVA), robust insulation (Class 130°C or 180°C), and copper conductors.

Applications: Large industrial machinery, motor control centers, and power distribution panels.

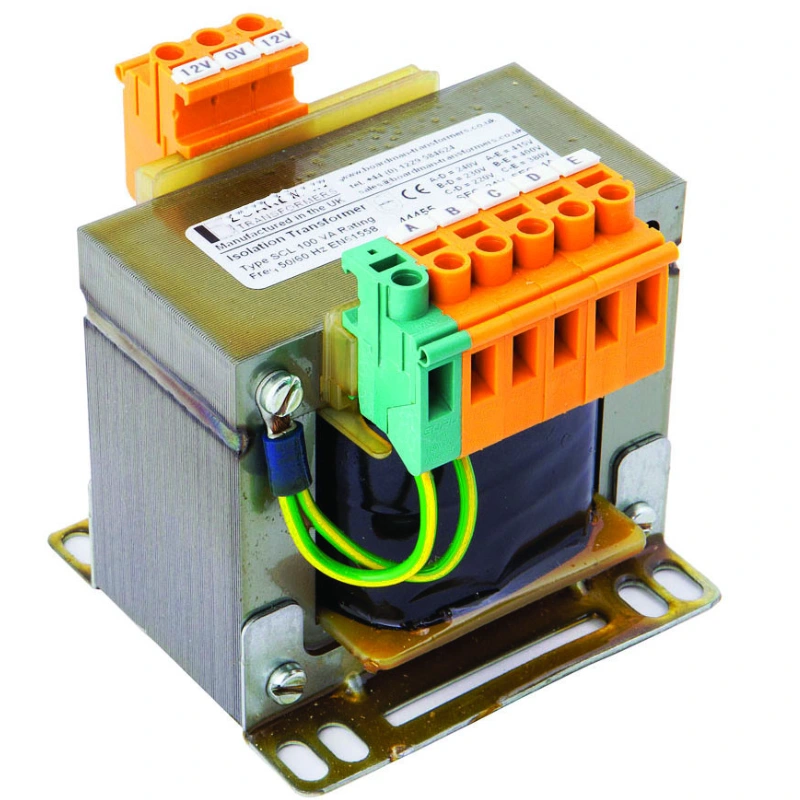

Isolation Control Transformers

Description: Provide electrical isolation between primary and secondary windings to protect control circuits from power surges, noise, and ground faults.

Key Features: Electrostatic shielding, noise filtering, and compliance with safety standards (UL/cUL).

Applications: Sensitive electronic equipment, medical devices, and noise-prone environments.

Furnace Control Transformers

Description: Specialized for heating systems (e.g., gas or electric furnaces), converting high voltage to low voltage for control circuits and ignition systems.

Key Features: Thermal resilience, stable output under cyclic loads, and often single-phase design.

Applications: Industrial furnaces, HVAC systems, and heating control panels.

Industrial Control Transformer Key Parts

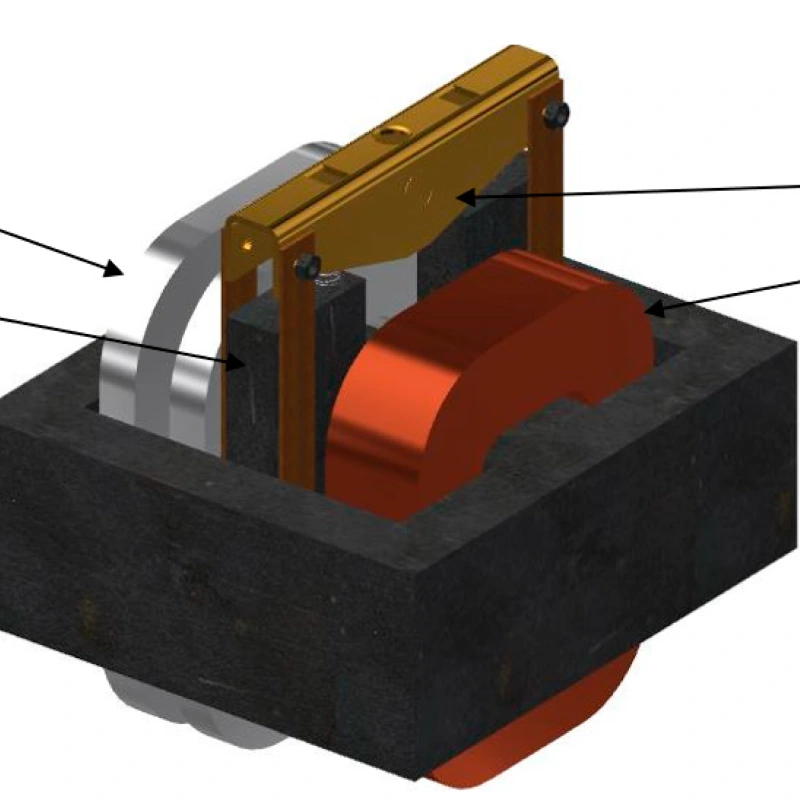

Primary Winding

Coiled wire connected to the input voltage source, generating magnetic flux to transfer energy into the transformer core.

Secondary Winding

Fewer turns of wire that deliver reduced, safe voltage to control circuits, ensuring stable power for devices.

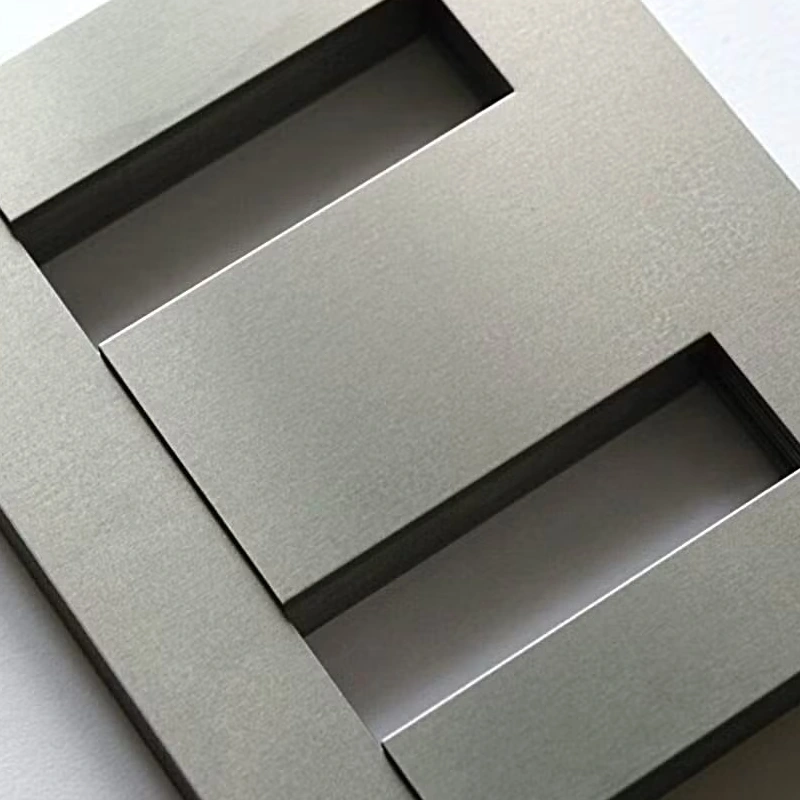

Laminated Core

Magnetic iron sheets stacked to reduce eddy current losses, efficiently guiding magnetic flux between primary and secondary windings.

Certificate

Application of Industrial Control Transformers in Different Industries

Control Cabinets

Electrical Panels

Telecom Signal Cabinets

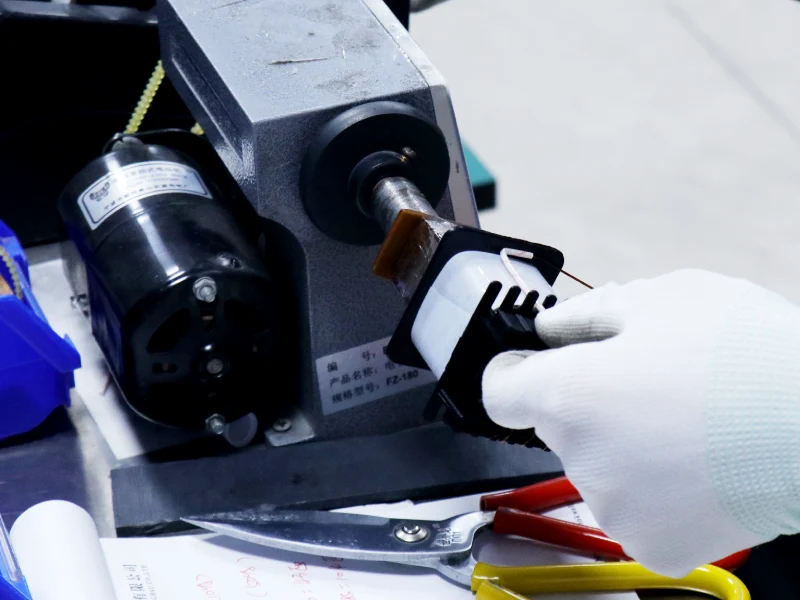

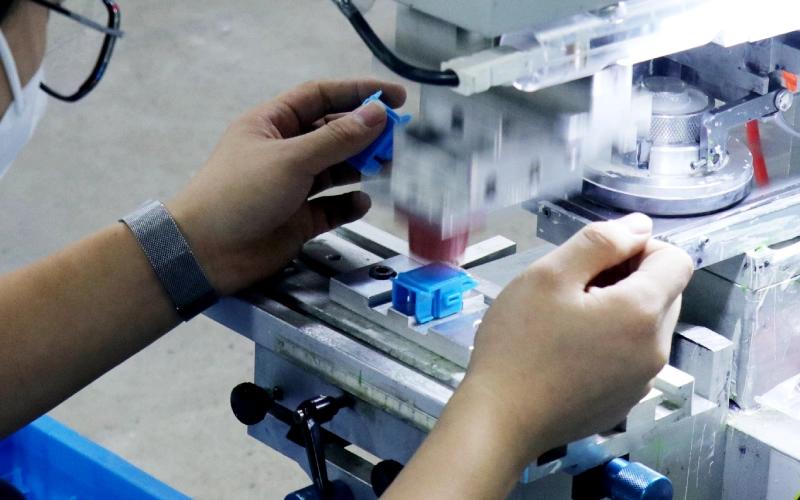

Our Factory

With 20 years of experience in designing and producing Industrial Control Transformers, our factory employs over 100 skilled workers dedicated to quality. Holding more than 50 patents, we continuously innovate to deliver advanced power conversion solutions. Our robust production capacity meets global demand, while strict compliance with international standards, such as UL, CE, and CSA, ensures reliable and safe operation for industrial control panels, motor starters, and automation applications worldwide .

Customize Your Industrial Control Transformer

Product Quality

Certified production with UL and CE approval ensures safe performance.

Each unit undergoes strict testing for reliability in control cabinets.

We design long-lasting transformers with reduced downtime for users.

Customization

We offer adjustable voltage and power capacities for industry needs.

Special enclosures ensure safety in harsh environments like telecom stations.

Our team develops tailored models to match your exact applications.

Cost Efficiency

Energy-saving designs cut electricity consumption for clients.

Bulk production lowers costs, benefiting wholesalers and distributors.

Fewer maintenance needs reduce long-term operational expenses.

Service & Delivery

We guarantee fast turnaround and reliable global logistics.

Our engineers provide expert consultation for transformer solutions.

After-sales support ensures smooth operation and quick technical help.

What is Industrial Control Transformers? How Does It Work?

An Industrial Control Transformer is a special type of step-down transformer designed to provide safe, stable voltage for control circuits in industrial environments. Unlike power distribution transformers, which manage large loads, these transformers supply small but essential devices such as relays, switches, contactors, and timers. Their main role is to ensure consistent, safe voltage for sensitive components, regardless of fluctuations in the primary power source.

How does it work?

The working principle of an Industrial Control Transformer is based on electromagnetic induction. The transformer has two main windings: the primary coil and the secondary coil, both wrapped around a laminated magnetic core.

When alternating current (AC) passes through the primary coil, it creates a magnetic field in the core. This magnetic field induces a voltage in the secondary coil, which delivers a reduced, stable voltage output. This process allows the transformer to step down high input voltage into the safer, lower voltage required for control circuits.

For example, a transformer may step down 480V input to 120V output, which can then safely power a relay in a control panel. Because industrial environments often experience voltage fluctuations, the transformer ensures the output remains stable, preventing damage to equipment.

Another key feature is isolation. The separation between primary and secondary windings ensures safety for operators and equipment. High-quality insulation and laminated cores reduce energy loss, making the transformer efficient and long-lasting.

Industrial Control Transformers are designed to handle sudden inrush currents, which occur when devices like contactors switch on. This makes them essential for automation systems, telecom cabinets, and electrical panels where stable, safe voltage is critical.

In short, they work by converting unstable high voltage into reliable, low voltage power, ensuring both equipment protection and operational safety.

What are the Benefits of Industrial Control Transformers?

Safe and Reliable Voltage Supply

Delivers stable voltage to control circuits, preventing overload and equipment failures in industrial and telecom systems.

Equipment Protection

Protects sensitive devices such as relays, timers, and PLCs from voltage spikes, ensuring long-term reliable operation.

Energy Efficiency

Minimizes energy loss through laminated cores and efficient windings, saving operational costs for businesses.

Customer Testimonials

FAQ of Industrial Control Transformers

How do I choose the right Industrial Control Transformer?

Selecting the right transformer depends on input voltage, output voltage, load capacity, and application type. Always match the transformer to your system requirements and safety standards. Contact us for professional guidance on choosing the best model.

Can Industrial Control Transformers be customized?

Yes, we provide customization based on input/output voltage, power rating, mounting style, and enclosure type. This helps meet specific industry requirements, improve efficiency, and reduce costs for distributors and wholesalers.

What are the common applications of Industrial Control Transformers?

They are widely used in control cabinets, electrical panels, telecom stations, and signal systems. These applications need stable voltage to protect sensitive components and ensure smooth, reliable operation of control equipment.

Are Industrial Control Transformers safe?

Yes, when designed and manufactured properly. Our transformers meet UL and CE certifications, undergo rigorous testing, and are built to protect equipment from overloads, voltage fluctuations, and overheating.

How long does an Industrial Control Transformer last?

Typically, they last 10–15 years depending on operating conditions. With quality materials, proper installation, and regular checks, their lifespan can extend longer, reducing replacement costs for industrial users.

What industries need Industrial Control Transformers most?

Industries using automation systems, telecom, manufacturing plants, and power distribution rely heavily on these transformers. They provide the safe and stable voltage needed for modern industrial operations.

How fast is your delivery?

Standard models are available quickly, and customized orders are produced and delivered within agreed timelines with full tracking support.

All-in-one Industrial Control Transformer Solutions for Your Project

We offer customized Industrial Control Transformers tailored to your needs—voltage range, power rating, enclosure type, and safety standards. With better cost efficiency, excellent quality, and timely delivery, we help customers gain stronger market competitiveness. Contact us for tailored solutions.