You need to keep the temperature inside your electrical cabinets below the optimal temperature set point—ideally 35–40°C (95–104°F). Most electrical components are rated for a temperature set point from -40°C up to 85°C. Sticking to this industrial temperature range: Safety temperature of cabinet electrical components is critical for safety, reliability, and long-term performance. If you go above the recommended temperature set point, you risk serious problems:

- 80 percent of all electrical control component failures happen due to temperature extremes.

- Most electrical components are designed for an ambient temperature set point of 40°–50°C.

- Every 10°C rise above the optimal temperature set point cuts the average lifespan by half.

| Temperature Increase (°C) | Lifespan Reduction (%) |

|---|---|

| 0 | 0 |

| 10 | 50 |

| 20 | 75 |

You want to protect your equipment, avoid downtime, and meet safety standards. Linkwell’s advanced temperature management solutions, including precise temperature set point controls, help you keep your electrical enclosures at the optimal temperature set point for safety and reliability.

Key Takeaways

- Keep the temperature inside electrical cabinets below 40°C (104°F) for optimal performance and longevity.

- Monitor internal heat sources like computers and motors, as they can significantly raise cabinet temperatures.

- Use proper ventilation and cooling solutions to prevent overheating and condensation inside your enclosures.

- Regularly check and maintain your climate control systems to catch issues early and ensure reliable operation.

- Consult with experts if you encounter persistent temperature or moisture problems to find effective solutions.

Industrial Temperature Range: Safety Temperature of Cabinet Electrical Components

Recommended Safe Range

You want your electrical cabinets to run smoothly and safely. To do that, you need to stick to the right industrial temperature range: safety temperature of cabinet electrical components. Most experts and recent research agree that you should keep the temperature inside your enclosure below 40°C (104°F). Many electrical devices can handle up to 50°C (122°F), but you get the best performance and longest lifespan if you stay under 40°C. If you keep the temperature lower, your equipment will last longer and work more reliably.

Here’s a quick look at what the latest international standards say about operating limits for electrical components:

| Standard | Description | Maximum Temperature Limits |

|---|---|---|

| IEC 61010-1 | Safety for electrical equipment for measurement and control | Defined limits for operator access areas |

| IEC 60950-1 | Safety for information technology equipment | Defined limits for surfaces and parts |

| IEC 60601-1 | Safety for medical electrical equipment | Categorized limits for operator contact |

| IEC 62368-1 | Safety for audio/video and communication technology equipment | Defined limits for touchable surfaces |

You should always check the acceptable operating limits for your specific components. Most manufacturers recommend keeping the temperature below 40°C. Here are some key points to remember:

- The maximum recommended temperature for most industrial cabinet electrical components is between 40°C and 50°C.

- You should aim to keep the enclosure temperature below 40°C for the best results.

- Always follow the acceptable operating limits listed in your equipment manuals.

If you follow these guidelines, you will stay within the industrial temperature range: safety temperature of cabinet electrical components and avoid many common problems.

Risks of Exceeding Limits

If you let the temperature inside your cabinet go above the acceptable operating limits, you put your equipment at risk. Excessive heat is one of the main reasons electrical components fail. In fact, high temperatures cause over 50% of electronic equipment failures. Even a small increase in temperature can have a big impact. For example, if the temperature inside your enclosure rises by just 18°F, the reliability of your components drops by 50%.

Here’s what can happen if you ignore the industrial temperature range: safety temperature of cabinet electrical components:

- Thermal Expansion and Contraction: When the temperature goes up and down, parts inside your cabinet expand and contract. This can cause wires to break or connections to loosen.

- Electrical Performance Drops: High temperatures can change how electricity flows through your components. You might see signal problems or even complete breakdowns.

- Material Degradation: Excessive heat speeds up the breakdown of insulation and other materials. This leads to early failures and safety hazards.

If you notice your cabinet feels warm to the touch or you see signs of condensation, you may already be outside the acceptable operating limits. Take action right away to bring the temperature back down.

You want to avoid these risks by always staying within the industrial temperature range: safety temperature of cabinet electrical components. This keeps your equipment safe, reliable, and long-lasting.

Linkwell takes your safety seriously. All Linkwell products meet strict international standards, including CE and UL certifications. Here’s a quick overview:

| Certification | Description |

|---|---|

| CE | Guarantees compliance with stringent safety standards worldwide |

| UL | Guarantees compliance with stringent safety standards worldwide |

When you choose Linkwell, you get products that help you maintain the right temperature and stay within the acceptable operating limits. This means fewer failures, less downtime, and more peace of mind.

Factors Affecting Electrical Enclosure Temperature

Internal Heat Sources

You might not realize how much heat your equipment generates inside an electrical enclosure. Devices like computers, transformers, and motors all give off heat during normal operation. The more power your equipment uses, the more heat it produces. For example:

- Computers and gaming consoles often need extra cooling because they run hot.

- Electric motors create heat from friction and magnetic fields.

- Transformers, even though they are efficient, still release some heat as a byproduct.

If you pack many devices into one cabinet, the internal temperature can rise quickly. That’s why you need to monitor the temperature and make sure you have enough ventilation. Linkwell’s Electrical Enclosure Fan helps move air and keeps things cool, so your components stay within the acceptable working environment.

Environmental Influences

The world outside your electrical enclosure matters just as much as what’s inside. If your cabinet sits in a hot factory or outdoors in the sun, the internal temperature can spike. Humidity, dust, and pollution also play a big role. Here’s a quick look at how different factors affect your enclosure:

| Environmental Factor | Impact on Temperature Inside Enclosures |

|---|---|

| Temperature Extremes | Overheating or condensation risks |

| Humidity | Condensation, corrosion, shorts |

| Dust and Pollution | Blocks heat dissipation, overheating |

| UV Radiation | Raises internal temperature |

You want to keep your electrical enclosure in an acceptable working environment. Linkwell’s Outdoor Enclosure protects your equipment from harsh weather, dust, and direct sunlight, helping you maintain a safe internal temperature.

Cabinet Design and Insulation

The way you design your electrical enclosure makes a huge difference. Good design helps with thermal dissipation and keeps your equipment safe. You should think about airflow, insulation, and even the color of your cabinet. Light-colored finishes and sun shields can help reflect heat. Quality insulation materials, like polyisocyanurate foam or polyurethane, keep the internal temperature stable. Proper ventilation is also key—without it, heat gets trapped and your equipment can overheat.

Tip: Always calculate the thermal balance for your enclosure. This helps you choose the right insulation and ventilation setup for your needs.

When you combine smart design with the right accessories, you create an acceptable working environment for your electrical components. Linkwell’s solutions make it easy to manage temperature and protect your investment.

Condensation Prevention and Temperature Control

Keeping your electrical enclosures dry and at the right temperature is just as important as keeping them cool. Condensation can sneak up on you and cause big problems. When warm, humid air inside your cabinet touches a cold surface, water droplets form. This moisture can damage your electrical components and lead to short circuits or corrosion. Rapid temperature changes, like a hot day turning into a cool night, make condensation even more likely. That’s why condensation prevention and stable thermal management are key for any industrial setup.

Recommended products

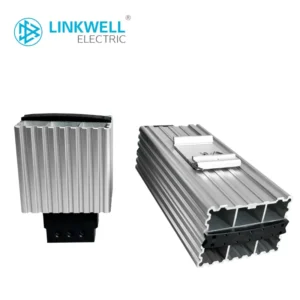

Linkwell Enclosure Heater Solutions

You can fight condensation with the right enclosure heating strategy. Linkwell’s anti-condensation heaters keep the air inside your cabinet warmer than the dew point. This stops moisture from forming on cold surfaces. These heaters use thermostats for precise temperature control, so you don’t waste energy. Some models even have built-in humidistats that turn on the heater only when humidity rises. With Linkwell’s anti-condensation heaters, you get reliable condensation prevention and longer equipment life.

Cabinet Air Conditioner and Thermostats

Sometimes, you need more than just heating. Cabinet air conditioners from Linkwell cool your enclosure, filter out dust, and lower humidity. This helps prevent overheating and keeps your equipment running smoothly. Thermostats let you set the perfect temperature, so your cooling system only works when needed. Experts suggest keeping your enclosure at least 5°C (9°F) warmer than the outside air to avoid condensation. A steady temperature means fewer thermal shocks and better thermal management.

Cabinet Cooling Fan

A good cooling fan can make a big difference in thermal management. Linkwell’s fans move air efficiently, keeping the temperature stable and reducing the risk of condensation. You should choose a fan with the right airflow rating (measured in CFM) based on your enclosure’s size and the heat your equipment produces. Linkwell fans stand out for their energy efficiency, durability, and ability to prevent heat buildup and moisture problems.

| Feature | Linkwell Fans | Competitors (General) |

|---|---|---|

| Energy Efficiency | Uses less power, eco-friendly features | Varies, often less efficient |

| Durability | Longer lifespan, less frequent replacement | May require more frequent replacements |

| Temperature Stability | Maintains stable temperatures | Often less effective in temperature control |

| Dust and Moisture Protection | Helps prevent rust and short circuits | Varies, may not provide adequate protection |

| Heat Buildup Prevention | Reduces risk of malfunctions | May allow for heat buildup |

Monitoring and Maintenance

You can’t manage what you don’t measure. Place sensors inside your cabinet to track temperature and humidity. Set up alerts for any sudden changes. Arrange your equipment for better airflow and thermal balance. Follow a regular maintenance schedule—daily, weekly, and monthly checks help catch problems early. Always follow manufacturer guidelines for your enclosure heating and cooling systems. Routine checks keep your thermal management system working at its best and help you avoid costly downtime.

Tip: Consistent monitoring and maintenance are your best tools for condensation prevention and stable thermal management. Don’t wait for problems—stay ahead with smart checks and the right equipment.

Troubleshooting and Expert Support

Identifying Hot Spots and Moisture

You want your electrical cabinet to run safely, so you need to spot trouble before it gets out of hand. Hot spots and moisture can sneak up on you, causing all sorts of problems. Here’s what you should look for:

- Water droplets or condensation inside the panel signal moisture issues.

- Rust on metal parts means water has gotten in.

- High humidity levels inside the enclosure can lead to the harmful consequences of moisture.

- Flaking insulation may point to overheating or poor overload protection.

- Use a thermal imager or infrared tester to find hot spots. These tools show you where the temperature is higher than it should be.

- Poor airflow or blocked vents can trap heat, raising the temperature and putting your equipment at risk.

If you see any of these signs, act fast. Moisture can cause short circuits, while hot spots can damage sensitive components. Regular checks help you catch problems early and keep your cabinet in top shape.

When to Consult Linkwell Experts

Sometimes, you need a little extra help. If you keep seeing high temperature readings or moisture problems that won’t go away, it’s time to call in the experts. Linkwell’s technical team can help you troubleshoot complex issues and recommend the best solutions for your setup.

| Criteria | Description |

|---|---|

| Temperature rating of components | Check the maximum temperature your devices can handle. |

| Heat output of components | Figure out how much heat your equipment makes during normal use. |

| Thermal conductivity of materials | Know how well your cabinet materials move heat, which affects cooling. |

Linkwell offers support services like solid state cooling units, dynamic air mixing systems, and sealed enclosures with internal heating. These solutions help you control temperature and moisture, keeping humidity below 60-70%. If convection cooling isn’t enough or you need active cooling, Linkwell’s experts can guide you to the right products and strategies.

Tip: Don’t wait until you have a major breakdown. Reach out to Linkwell for advice on temperature management and moisture control. Their team stays up-to-date on the latest technology and best practices, so you get reliable answers fast.

You want your electrical cabinets to stay within a safe temperature range—ideally below 40°C. This keeps your equipment reliable and extends its life. To manage temperature and prevent condensation, try these strategies:

- Use heating elements to keep air above the dew point.

- Install ventilation or air conditioning for steady temperature control.

- Control humidity and seal your enclosure well.

When you select temperature management products, remember to:

- Check your equipment’s heat load.

- Review the maximum allowable temperature.

- Choose the right cooling method for your setup.

If you need help, reach out to Linkwell’s experts. Take charge of your temperature management now to protect your investment.

FAQ

What is the ideal temperature for my electrical cabinet?

You should keep your cabinet below 40°C (104°F). Most components work best in this range. Staying under this limit helps you avoid failures and extend equipment life.

How do I know if my enclosure needs extra cooling or heating?

If you notice high temperatures, condensation, or frequent equipment failures, you need extra cooling or heating. Use sensors to monitor conditions. Linkwell offers fans, heaters, and air conditioners for every setup.

Can I use Linkwell heaters and fans in outdoor or wet environments?

Yes, you can. Linkwell’s heaters and fans have IP65 ratings. They resist dust and water. You get reliable performance even in harsh conditions.

How often should I check and maintain my enclosure’s climate control system?

Check your system monthly. Clean filters, inspect for moisture, and test sensors. Regular maintenance keeps your equipment safe and helps you catch problems early.