If you want to know how to calculate prospective fault current in cables and switchgear, you first need to understand what it means. Prospective fault current is the highest current that can flow when a fault happens, like a short circuit. Getting this number right helps you pick protective devices that keep your system safe and reliable. Linkwell’s Electrical Control Panel, electrical power distribution box, and Traffic Signal Cabinet help manage fault current by making sure devices meet proper ratings. When you calculate accurately, you prevent thermal damage and follow industry standards.

Key Takeaways

- Understanding prospective fault current is crucial for electrical safety. It helps prevent electrical fires and ensures protective devices can handle potential faults.

- Accurate calculations require knowing system voltage and impedance. Gather data on cables, transformers, and protective devices to ensure precise results.

- Use a fault current calculator for quick and reliable calculations. This tool helps you assess fault current at various points in your system.

- Always match protective devices to the calculated fault current. This prevents equipment failure and enhances safety during faults.

- Regularly update your fault current calculations. Changes in equipment or system layout can affect safety and compliance.

Prospective Fault Current Basics

What Is Prospective Fault Current

When you work with electrical systems, you often hear the term prospective fault current. This is the highest current that can flow through your system if a short happens. International standards like IEC and UL call this the available fault current. You might also see it called Ik in IEC documents. The available fault current is the largest amount of current that can move through a point in your system during a short-circuit event. This value depends on your system’s voltage and impedance.

Here’s a quick table to help you understand the terms:

| Term | Definition |

|---|---|

| Available Fault Current | The largest amount of current capable of being delivered at a point on the system during a short-circuit condition according to NEC 2020. |

| Ik (IEC) | Equivalent term used in IEC standards for the available fault current. |

You need to know the available fault current at every important spot in your system. This includes places like the main panel, distribution box, or even inside a traffic signal cabinet. Linkwell has years of experience with low-voltage systems and always follows international standards. Their products help you measure and manage available fault current safely.

Why It Matters

You might wonder why available fault current is so important. If you ignore it, you risk big problems. When a short happens, the available fault current can get very high. If your protective devices can’t handle it, you could face electrical fires, explosions, or even injuries.

Here’s what knowing your available fault current helps you do:

- Prevent electrical fires and explosions by making sure your devices can handle the highest possible current during a short.

- Pick the right circuit breakers and fuses for your system.

- Predict how much energy a short might release, which helps you choose the right safety gear.

- Reduce downtime and avoid costly repairs by stopping system failures before they start.

- Follow safety rules and keep your workplace safe.

Linkwell’s electrical control panels and power distribution boxes are built to handle high available fault current. They meet strict standards like UL and IEC, so you can trust them to keep your system safe during a short.

How to Calculate Prospective Fault Current

Calculation Points

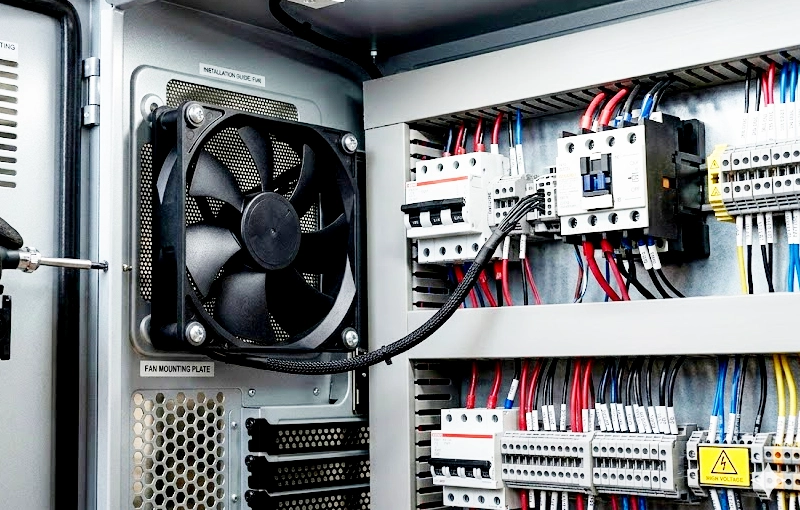

You want to know how to calculate prospective fault current in your system. Start by picking the right spots for fault current calculation. The most important points are where you install protective devices, like circuit breakers or fuses. You should check the main incoming supply, each branch circuit, and every panel or distribution box. For example, if you use a Linkwell Electrical Control Panel, you need to calculate fault current at the main busbar and at each outgoing circuit. In a Linkwell electrical power distribution box, look at every feeder and branch circuit.

Here’s a quick table showing the main factors that affect fault current calculation:

| Factor | Description |

|---|---|

| Fault type | Changes the number and location of faulted phases, impedance of the fault path, and size of fault current. |

| Power source | Depends on the type and setup of the power sources in your system. |

| Network topology | Affects how current spreads and the total impedance in your circuit. |

| Protective devices | Adds extra impedance, which can lower fault current and change its duration. |

| Fault location | The distance from the power source changes the impedance and the fault current. |

| Fault resistance | Extra resistance in the fault path lowers fault current and raises fault voltage. |

You need to check each calculation point carefully. If you miss a spot, you might choose the wrong protective device. That can lead to overheating or even damage during a fault.

System Data Needed

Before you start any fault current calculation, gather all the system data. You need to know the impedance of every item in your circuit. This includes cables, transformers, busbars, and even the protective devices. Sometimes, the fault impedance is not zero, and it can be hard to estimate. Rotating machines, like motors or generators, can add extra fault current. The first few cycles after a fault may have a DC offset, which makes the fault current higher than you expect.

Here’s a checklist for the data you need:

- Impedance values for all cables, transformers, and devices in the circuit.

- Fault impedance, which may not be zero.

- Contribution from motors or generators.

- DC offset in the first cycles of a fault.

- Earth impedance for earth fault calculations.

- Inductance effects for DC system faults.

Cable length and cross-sectional area matter a lot. Longer cables increase impedance and lower fault current. If you change cable length by 10% in a large cable, you get about a 5% change in fault current. For smaller cables, the effect is even bigger. Always measure cable length and size before you calculate fault current.

Fault Current Formula

Now you’re ready for the key formulas for fault current calculation. You want to know how to calculate fault current in a circuit, so let’s break it down step by step. These steps work for any Linkwell Electrical Control Panel or electrical power distribution box.

- Find the System Voltage

Look at your panel or distribution box. Check the voltage rating, like 480V or 230V. - Calculate Total Impedance

Add up the impedance from the power source to the fault point. Include cable impedance, transformer impedance, and any device impedance.

Use this formula:Ztotal = Zsource + Zcable + Ztransformer + Zdevice - Apply the Short Circuit Current Calculation Formula

Use the main formula for fault current calculation:Isc = Vsystem / ZtotalThis gives you the prospective fault current at the calculation point. - Consider Fault Type

Decide if you have a three-phase fault, line-to-line fault, or earth fault. Each type changes the calculation. For earth fault, include earth impedance. - Adjust for Cable Length and Size

Longer cables mean higher impedance, so lower fault current. Smaller cables have a bigger effect. Always update your numbers if you change cable size or length. - Check for Initial Fault Current Peak

The first peak after a fault can be much higher than the steady-state value. If you ignore this, you might pick cables or switchgear that can’t handle the stress. - Review Thermal and Mechanical Stress

Make sure your busbars and devices can handle the heat and force during a fault. If you skip this, you risk bending or breaking parts. - Use Computer-Aided Tools

For big systems, use software to model your circuit and run a short circuit test. This helps you calculate fault current more accurately. - Maintain System Data

Update your system model and data often. If you change your circuit, recalculate fault current. This keeps your protection up to date.

Here’s a tip: Always use the key formulas for fault current calculation at every calculation point. If you want to know how to calculate available fault current, use the same steps. For maximum fault current, use the lowest possible impedance. If you need to calculate fault current for ground fault or earth fault, include earth impedance in your formulas.

Note: Regular maintenance and system modeling help you keep your fault current calculation accurate. Use computer-aided analysis and update your data often.

If you follow these steps, you’ll know how to calculate fault current for any circuit. You’ll pick the right protective devices and keep your system safe. Linkwell products make this process easier by providing clear data and certified components for every panel and distribution box.

Prospective Short-Circuit Current in Switchgear

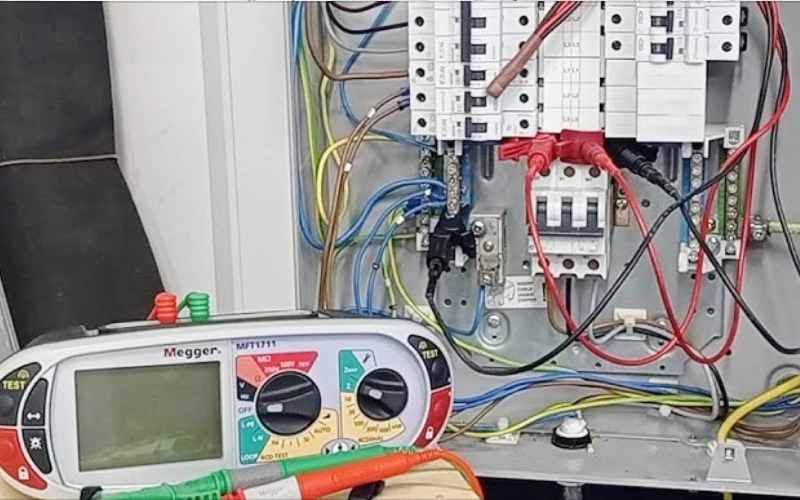

Impedance and Measurement

When you want to figure out the prospective short-circuit current in switchgear, you need to look at the impedance of the whole system. Impedance is like a roadblock for electric current. The lower the impedance, the higher the maximum prospective fault current during a short. You measure this at the main switch or any switchgear that connects right to the power source. This gives you the most accurate number for the maximum prospective fault current.

You can use two main tests to measure this:

| Test Type | Description |

|---|---|

| Prospective Short Circuit Test (PSC) | Measures the highest short circuit current that can flow, based on the voltage and impedance of your supply system. |

| Prospective Fault Current Test (PFC) | Checks the fault current at the source under certain conditions. |

- PSC usually gives a higher value than PFC.

- You base the calculation for prospective short-circuit current on the normal voltage of your circuit.

- The short circuit current can change a lot depending on your system type.

You need to check the impedance for every type of fault. For example, a three-phase fault will have a different current than a phase-to-phase fault or a phase-to-neutral fault. Always test at the main switchgear, like a Linkwell Traffic Signal Cabinet, to make sure your numbers are right.

Device Ratings

You must match your switchgear’s ratings to the maximum prospective fault current. If you don’t, your equipment might fail during a short. Standards like IEC/EN 61439-1 say you have to show the maximum prospective short-circuit current at the input of your switchgear. The short-circuit protective device, like a breaker, must have a rating (Icu or Icn) that meets or beats this number.

Here’s a quick look at some important standards:

| Standard | Description |

|---|---|

| ANSI/IEEE C37.20.1 | Rules for metal-enclosed low-voltage switchgear |

| UL 1558 | Covers low-voltage power circuit breaker switchgear |

| UL 1066 | For AC and DC power circuit breakers in enclosures |

- The short circuit current withstand rating (SCCR) shows how much short circuit current your switchgear can handle for at least four cycles.

- This rating keeps your bus bars safe during a three-phase fault or a phase-to-phase fault.

- The SCCR must match the lowest-rated breaker in your panel.

If you use Linkwell’s certified Traffic Signal Cabinet or other switchgear, you know you’re meeting these standards. You can trust that your equipment will handle the maximum prospective fault current, whether you face a three-phase fault, a phase-to-neutral fault, or a short at any point in your system.

Fault Current Calculator and Practical Examples

You want to make sure your system is safe. You need to know the exact fault current at every point. That’s where a fault current calculator comes in. This tool helps you get accurate numbers fast. You can use it for Linkwell Electrical Control Panels, electrical power distribution boxes, and switchgear. Let’s walk through two practical examples so you know how to use the fault current calculator in real life.

Cable Example

Suppose you have a Linkwell Electrical Control Panel in your factory. You want to check the fault current at the main busbar. Here’s how to use the fault current calculator:

- Gather your transformer specs:

- Transformer Size: 500 kVA

- Secondary Voltage: 400 V

- Impedance: 5%

- Choose your system type. Is it single-phase or three-phase?

- Enter these values into the fault current calculator.

- The calculator gives you the estimated fault current.

- Use this result to check if your circuit breakers and cables can handle the fault current.

You can repeat this process for every cable in your system. The fault current calculator helps you avoid mistakes. You get the right numbers for every branch and feeder. If you change cable length or size, just update the values in the fault current calculator. You’ll always have the latest data.

Switchgear Example

Let’s say you need to check the fault current at a Linkwell Traffic Signal Cabinet. You want to know how to use the fault current calculator for this switchgear:

- Collect all the specs for your incoming supply and transformer.

- Pick the system type in the fault current calculator.

- Enter the voltage, transformer size, and impedance.

- The fault current calculator shows you the maximum fault current at the switchgear.

- Use this number to pick the right breaker and make sure your cabinet meets safety standards.

Modern fault current calculator tools do more than just basic math. They let you print labels, size fuses, and check conductor ratings. Some advanced fault current calculator software, like ETAP Short Circuit Software, helps you compare values, generate reports, and analyze faults at different points. You can even check the X/R ratio with the fault current calculator, which helps you pick the best protection devices.

Here’s a quick table showing what today’s fault current calculator tools can do:

| Tool Name | Purpose | Key Features |

|---|---|---|

| Fault Current Calculator 4.2.0 | Calculate and print available fault current | Label marking, fuse sizing, conductor selection, single/three-phase support |

| ETAP Short Circuit Software | Analyze balanced/unbalanced faults | Compare ratings, generate reports, graphical tools, advanced analyzers |

If you want to know how to use the fault current calculator for your Linkwell products, just follow the steps above. You’ll get reliable results every time. The fault current calculator makes your job easier and keeps your system safe.

Tip: Always use a fault current calculator when you upgrade your system or add new equipment. You’ll catch problems before they happen.

The fault current calculator is your best friend for electrical safety. You can use it for cables, switchgear, and any Linkwell panel. Try it out and see how much easier your calculations become.

Compliance and Device Selection

Standards and Safety

You want your electrical system to be safe and reliable. That means you need to follow the right standards when you calculate prospective fault current and pick your protective device. Standards like UL, IEC, and others set the rules for how you build and test panels, switchgear, and distribution boxes. Linkwell’s certified products, like the Electrical Control Panel and Traffic Signal Cabinet, help you meet these strict requirements.

Here’s a quick look at some of the most important standards for fault current calculation and device selection:

| Standard Name | Description |

|---|---|

| Australian Standard AS3000 | Wiring rules for electrical installations in Australia. |

| IEC60906 | International standard for determining prospective short-circuit current. |

| Service and Installation Rules (SIR) | Guidelines for electrical installations in New South Wales, Australia. |

You also need to pay attention to UL 508A and IEC standards. These tell you what components you can use and how to assemble your panel safely. For example, UL 508A says every protective device, like a circuit breaker or contactor, must meet UL standards. IEC standards make sure your devices work well together, no matter where you install them.

Tip: Always keep records of your fault current calculations. Mark your service equipment with the maximum available fault current and update it if you make changes. This helps you pass inspections and keeps your system safe.

Choosing Protection Devices

Now, let’s talk about how you pick the right protective device. You start with your calculated prospective fault current. Your protective device must have a breaking capacity that meets or beats this value. If it doesn’t, you risk serious damage or even danger.

Here’s a table to help you remember what to check:

| Criteria | Description |

|---|---|

| Short-circuit breaking capacity | Must match or exceed the prospective fault current at the installation point. |

| Coordination with upstream devices | If your device can’t handle the fault current, make sure an upstream device can. |

| Electrical characteristics | Check if your system uses AC or DC, and confirm the voltage. |

| Environmental factors | Think about temperature and climate where you install the device. |

| Protected components | Look at the cables, busbars, and what you’re protecting. |

| Operational specs | Decide if you need remote control or extra contacts. |

| Installation regulations | Make sure you follow rules for electric shock and thermal protection. |

If you pick a protective device with a rating that’s too low, you could see devices rupture, lose protection, or even face safety risks from arcing faults. Always match your protective device to the calculated fault current. If you’re not sure, coordinate with an upstream breaker that can handle the load.

- Choose a protective device with the right breaking capacity.

- Check the environment and installation rules.

- Make sure your device protects all cables and busbars.

- Update your documentation after any changes.

When you use Linkwell’s certified panels and cabinets, you get products that already meet these standards. That makes your job easier and your system safer.

You now know how to calculate prospective fault current and why it matters for safety and compliance. Using certified products like Linkwell Electrical Control Panel, electrical power distribution box, and Traffic Signal Cabinet helps you manage prospective fault current with confidence. These products meet strict standards, as shown below:

| Certification/Standard | Applicable Region | Focus Area | Key Compliance Aspects |

|---|---|---|---|

| UL 508A | U.S. & Canada | Industrial Control Panels | Electrical safety, part selection, wiring, enclosure requirements |

| NFPA 70 (NEC) | U.S. & Canada | Electrical Installation | Safety rules for electrical system installations |

| NFPA 79 | U.S. & Canada | Machinery Safety | Safety for control panels in machinery |

| IEC 61439 | International | Low-voltage Assemblies | Global system testing and design standards |

For accurate prospective fault current calculations and device selection, keep this checklist handy:

- Verify system voltage and insulation level.

- Calculate the maximum fault current for proper breaker selection.

- Assess load current and plan for future growth.

- Match circuit breakers to their environment.

- Evaluate endurance for your application.

- Specify control and protection features.

- Consider total cost of ownership.

If you need expert help with prospective fault current or want a custom solution, reach out to Linkwell. You’ll get support every step of the way.

FAQ

What is the difference between prospective fault current and short-circuit current?

Prospective fault current is the highest current that could flow during a fault. Short-circuit current is the actual current that flows when a short happens. You use the prospective value to pick safe devices.

How often should I recalculate fault current in my system?

You should recalculate fault current whenever you upgrade equipment, change cable lengths, or add new loads. Regular checks help you keep your system safe and compliant.

Can I use a standard calculator for fault current calculation?

No, you need a specialized fault current calculator or software. These tools consider system voltage, impedance, and other factors. They help you get accurate results fast.

Why do cable length and size matter in fault current calculation?

Longer cables and smaller sizes increase impedance. This lowers the fault current. Always measure and update cable details before you calculate.