You might ask what makes static pressure vs airflow fans different. Static pressure fans are effective in environments with significant resistance. They excel when air needs to pass through small spaces or filters. On the other hand, airflow fans are designed to move a larger volume of air at once, making them more suitable for open areas. Choosing between static pressure and airflow fans is crucial as it helps your equipment stay cool and safe.

Selecting the right fan prevents overheating and ensures your systems operate efficiently.

| Fan Type | Strengths | Weaknesses |

|---|---|---|

| Static Pressure | Works well with resistance, operates quietly, and provides effective cooling | Moves less air in open spaces |

| Airflow Fans | Moves a significant amount of air, ideal for open areas | Not effective with blockages, can be noisy |

Key Takeaways

- Static pressure fans are good for small spaces with things in the way. They push air through filters and radiators very well.

- Airflow fans are best for open spaces. They move a lot of air fast. This helps cool things in places with more room.

- Picking the right fan stops things from getting too hot. Use the right fan for your equipment to help it work better.

- Check and clean filters often. This keeps airflow strong and helps fans work well.

- Think about fan size and how loud it is. Pick fans that fit your cabinet and are quiet for comfort.

Static Pressure Fans

Design and Function

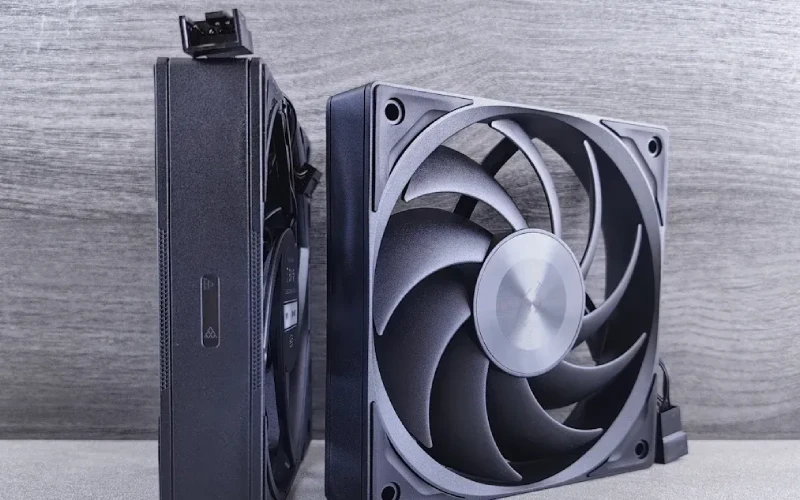

Static pressure fans are used where air must go through tight spots or things in the way. These fans push air hard, so they are not like airflow fans that work best in open spaces. Static pressure fans can keep moving air even when there is something blocking the way, like filters or thick fins. You see these fans in computers and machines that need cooling. The blades on static pressure fans are shaped to make strong pressure. This helps air move through things that block it. This design helps keep equipment cool when you need both airflow and static pressure.

Tip: If you need to cool something with lots of fins or filters, static pressure fans work better than airflow fans.

Static pressure fans are special because they can push air through things that block it. You can see this when you compare them to airflow fans, which do not work well in blocked places. The airflow-static pressure features make these fans good for tough spots.

Applications

You use static pressure fans in many places where air has to move past things in the way. Here are some common uses:

- Cooling radiators in computers and cars

- Heat sinks for electronics

- Places with dust filters or mesh screens

High static pressure fans help keep air moving through thick fins in radiators and heat sinks. You need these fans to keep things cool. The static pressure features help you get better heat transfer, especially when you use top induced draft setups. Studies show this setup can make heat transfer about 14% better. You also get better results if you raise the total fan pressure or increase oil flow in radiators.

Here is a table showing how static pressure fans work in tough places:

| Fan Type | Power Draw Change | Airflow Rate Change | Efficacy Improvement |

|---|---|---|---|

| ECM | 46% – 58% increase | Maintained airflow | 43% higher than PSC |

| PSC | 10% – 23% decrease | Reduced airflow | Lower efficacy |

You can see that static pressure fans are best when airflow-static pressure features matter. You should pick these fans for places with lots of things blocking the air.

Fan Airflow and Airflow Fans

Design and Function

It is important to know how airflow fans work. Airflow fans move a lot of air in open spaces. Their blades are wide and shaped to cut through air. This shape helps the fan push more air with less trouble. Airflow fans often have fewer blades than other fans. Fewer blades let them move air faster. The size of the fan also matters. Bigger fans can move more air and keep the speed even.

Here is a table that shows how airflow fans and static pressure fans are different:

| Feature | Airflow Fans | Static Pressure Fans |

|---|---|---|

| Blade Shape | Fewer, wider | More, closely spaced |

| CFM | Higher | Moderate |

| Static Pressure | Lower | Higher |

| Best For | Case intake/exhaust | Radiators, heatsinks |

| Noise Level | Often quieter | Can be louder under load |

Airflow fans are best for moving air where nothing blocks it. You get the best cooling when you use them in open places. The fan airflow helps keep things cool and stops hot spots from forming.

Applications in Electrical Enclosures

You can find airflow fans in many places. They are used in open cases, control cabinets, and telecom boxes. These fans help keep electronics from getting too hot. When you put an airflow fan in a cabinet, it keeps air moving inside. This helps keep the temperature steady and stops overheating.

The Linkwell Electrical Enclosure Fan is a good example. You can use it in big cabinets for industry or telecom. It moves up to 265 m³/H of air and is quiet at 29-35 dB(a). The fan airflow keeps your equipment safe, even in tough places. It also has CE and UL certifications for safety and quality.

Good airflow can stop over 70% of equipment problems. Studies show that using airflow fans can make equipment last up to 40% longer. You save money and have less downtime with these fans. If you want the best cooling, pick a fan that fits your cabinet and heat needs.

Tip: Check and clean filters often to keep airflow strong and get the most air moving.

Static Pressure vs Airflow Fans

Key Differences

Static pressure fans and airflow fans work in different ways. Static pressure fans push air through tight spots and things in the way. Airflow fans move a lot of air in open spaces. Knowing these differences helps you pick the right fan for your needs.

Here is a table that shows the main technical differences:

| Feature | Airflow Fans | Static Pressure Fans |

|---|---|---|

| CFM Rating | High, suitable for open environments | Lower, designed for confined spaces |

| Noise Levels | Quieter at lower RPMs | Louder at higher RPMs |

| Performance in Restrictive Settings | Diminished performance, risk of overheating | Maintains performance under pressure |

| Ideal Use Case | General case ventilation | Effective air movement through radiators/dust filters |

Airflow fans have fewer and wider blades. Static pressure fans have more blades that are close together. This helps static pressure fans push air through things like filters or thick fins.

Use airflow fans for open cabinets or places where air can move easily. Static pressure fans are better for spots with filters, radiators, or screens. If you want to cool a control cabinet or telecom box, think about how much resistance the air will face.

Tip: Look at your cabinet before picking a fan. If there are lots of filters or tight spaces, static pressure fans will work better.

Performance Comparison

You can measure how well a fan works in three ways: static pressure, airflow, and energy efficiency. Static pressure shows how well a fan pushes air against things in the way. Airflow tells you how much air the fan moves. Energy efficiency shows how much power the fan uses to do its job.

Here is a table with these metrics:

| Metric | Description |

|---|---|

| Static Pressure | Indicates the ability of the fan to overcome resistance in the system. |

| Airflow | Measures the volume of air moved by the fan, crucial for ventilation efficiency. |

| Energy Efficiency | Assesses how effectively the fan uses energy relative to its output, important for cost savings. |

Static pressure fans keep working well even when air has to go through things. Airflow fans do not work as well if something blocks the air. That is why you need to match the fan to your cabinet.

Tests show that 38mm fans have more airflow-static pressure than 25mm fans. Stacking fans can make static pressure even higher. A fan works best when it balances airflow and pressure. The best efficiency comes from finding the right mix.

Noise is important too. Fans under 30dB are quiet. If noise goes over 35dB, you will hear it. Static pressure fans can be louder at high speeds, but new designs help make them quieter. Some new fans can reach high static pressure without making much noise.

Things like temperature and humidity can change how fans work. Hot air is less dense, so airflow-static pressure changes. Always check things like CFM, static pressure, and air density before you pick a fan.

Energy use matters too. High static pressure fans save energy in places with lots of resistance. These fans can use up to 30% less energy, especially with smart controls. Airflow fans use more energy when moving lots of air in open spaces.

Here is a table showing best-use scenarios:

| Scenario | Description | Benefits |

|---|---|---|

| High Heat Equipment | Equipment generating significant heat requires cooling solutions. | Protects investment and maintains operational efficiency. |

| Enclosed Cabinets | Limited airflow in cabinets leads to heat buildup. | Cabinet fans help manage airflow, preventing overheating and ensuring equipment reliability. |

| HVAC System Design | Proper static pressure is crucial for effective HVAC operation. | Ensures efficient airflow distribution and improves indoor air quality. |

You need to know about airflow and static pressure when picking fans for cabinets. Linkwell Electrical Enclosure Fans have models with high airflow-static pressure and strong static pressure ratings. You can pick the right fan for your cabinet based on how much resistance and cooling you need. Linkwell fans meet ISO and CE standards, so they are safe and reliable.

New fan designs use AI controls and better blades to improve airflow-static pressure and save energy. Linkwell uses these features in its fans, so you get smart and efficient cooling for control cabinets and telecom boxes.

Note: Always check for certifications and energy ratings when you pick a fan. Linkwell fans give you high performance and meet global standards, so they are a good choice for industry.

Combination of Fan Airflow and Static Pressure

Choosing the Right Fan

You need to understand how both airflow and static pressure work together when you pick a fan for your equipment. The combination of fan airflow and static pressure matters because every cabinet or enclosure has its own cooling needs. Some cabinets have open spaces, while others have filters, ducts, or tight corners that block air. You must look at both airflow and static pressure to make sure your equipment stays cool and safe.

When you choose a fan, always check how much heat your machinery makes and what temperature you want inside the cabinet.

Here are some important steps to help you select the right fan:

- Find out how much heat your equipment produces.

- Decide the temperature you want to keep inside the cabinet.

- Calculate the airflow needed to remove the heat and reach your target temperature.

- Look at the airflow and static pressure ratings of different fans.

- Pick a fan that matches your airflow needs and can handle the resistance inside your cabinet.

You should also think about the type of fan. Axial fans move air straight through and work well in open spaces. Centrifugal fans push air out to the sides and can handle higher static pressure. Each type fits different cabinet designs.

Tip: Always match the fan size to your cabinet. Make sure the fan fits and meets your cooling needs.

You also want a fan that lasts a long time and has safety certifications. Choose fans with a lifespan of over 50,000 hours and look for CE or UL marks. If you care about noise, pick fans that run below 30dB. This keeps your work area quiet.

Airflow-Static Pressure in Industrial Cabinets

Industrial cabinets and telecom enclosures often have filters, wiring, and other parts that block air. In these cases, you need to balance airflow and static pressure. If you only focus on airflow, you might not get enough cooling because the air cannot move past the blockages. If you only focus on static pressure, you might not move enough air to cool your equipment.

The Linkwell Electrical Enclosure Fan gives you a good balance of airflow and static pressure. You can use it in control cabinets, telecom boxes, and other industrial enclosures. This fan moves enough air to cool your equipment and has the power to push air through filters and tight spaces. It also runs quietly and fits many cabinet sizes.

Here are some tips for getting the best airflow and static pressure in your cabinet:

- Use a front-in, rear-out airflow design. This setup helps air move smoothly through the cabinet.

- Install dust filters at the air intake. Filters keep dust out and help your fan last longer.

- Clean filters and fans often. Dust can block airflow and lower static pressure.

- Make sure the fan fits the space and mounting holes in your cabinet.

- Check the energy efficiency of the fan. Fans that use less power save money over time.

| Factor | Why It Matters | What To Do |

|---|---|---|

| Airflow | Moves heat out of the cabinet | Choose a fan with enough airflow |

| Static Pressure | Pushes air through filters and tight spaces | Pick a fan with strong static pressure |

| Fan Size | Must fit your cabinet | Measure before you buy |

| Noise Level | Affects comfort and safety | Look for fans under 30dB |

| Lifespan & Certification | Ensures long-term, safe operation | Select fans with CE/UL marks |

You should always check both airflow and static pressure ratings before you buy a fan. The right balance keeps your equipment cool and running well. Linkwell fans help you get this balance, so your control cabinets and telecom enclosures stay safe and efficient.

Note: Good airflow and static pressure can prevent most overheating problems and extend the life of your equipment.

You should understand how static pressure fans and airflow fans are different. Static pressure fans are best for small, tight places like radiators or thick heatsinks. Airflow fans are good for open spots, like where air comes in or goes out of a case.

- If you use the wrong fan, things can get too hot and use more energy.

- People often make mistakes by choosing the wrong size or putting fans in the wrong way.

| Application Tip | Result |

|---|---|

| Pick the right fan for your cabinet | You get better cooling and spend less money |

Pick Linkwell Electrical Enclosure Fans if you want cooling you can trust in cabinets or factories. This helps keep your equipment safe and saves you money in the long run.

FAQ

What is the main difference between static pressure fans and airflow fans?

Static pressure fans are good for pushing air through small spaces or filters. Airflow fans are better at moving lots of air in open places. You should pick the fan that matches what your equipment needs.

How do I know which fan type my cabinet needs?

Look inside your cabinet for filters or tight spots. If you find these, use a static pressure fan. If your cabinet is open, an airflow fan is the best choice.

Why does fan airflow matter in electrical enclosures?

Fan airflow helps take heat out of your enclosure. Good airflow keeps your equipment cool and stops it from getting too hot. This makes your devices work longer.

Can I use Linkwell Electrical Enclosure Fans in harsh environments?

Yes, you can use Linkwell Electrical Enclosure Fans in tough places. These fans are made with weatherproof materials. They give safe and long-lasting cooling for industrial and telecom cabinets.