Custom Terminal Block Connector Manufacturer in China

Our Terminal Block Connector is designed for control cabinets, electrical enclosures and telecom signal cabinets—robust, reliable and easy to install in high-volume industrial settings. At Linkwellelectrics we manufacture with precision, deliver high quality and support bulk orders for distributors and brands.

Linkwell Electrics - Your Trusted Terminal Block Connector Manufacturer from China

Global Partnership

Terminal Block Connector By define connection style

As a dedicated supplier of Terminal Block Connector solutions we provide services including technical specification support, custom branding, prompt logistics, and after-sales assistance for wholesalers and OEM partners—contact us to explore your options.

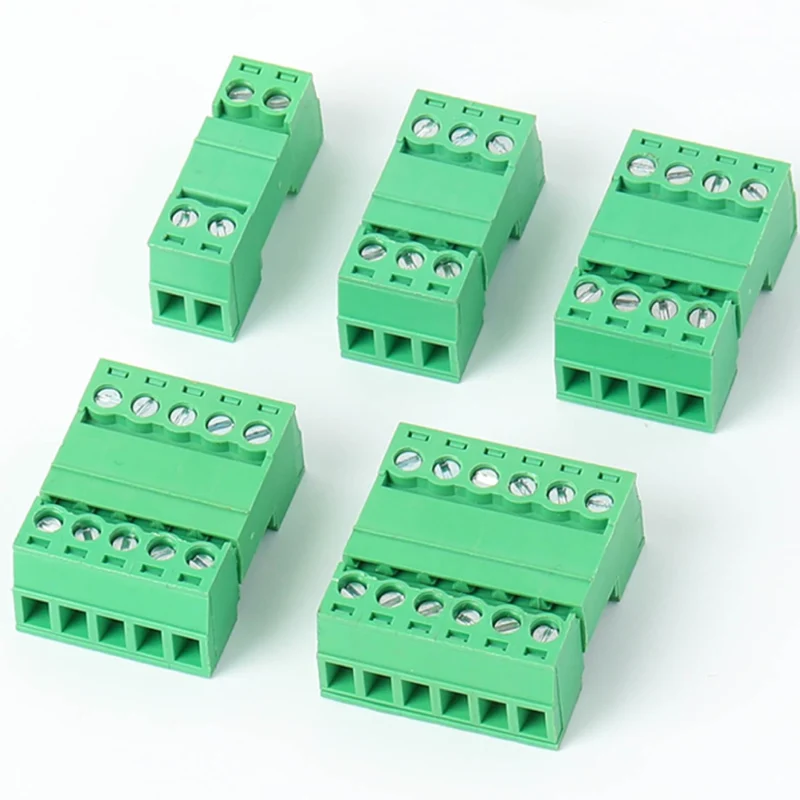

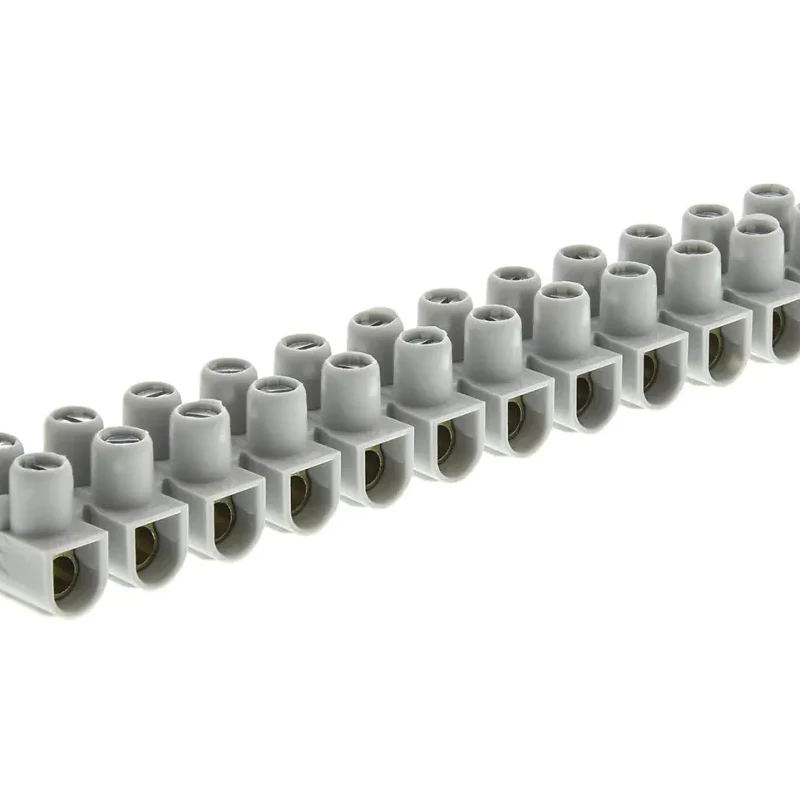

screw terminal connector block

A connector block where wires are secured by tightening screws, widely used in control cabinets and electrical enclosures. Ideal for distributors supplying panel-builders who require reliable, reusable wiring connections.

spade connector terminal block

Terminal block designed to accept spade-type terminals, enabling quick connections/disconnections in telecom signal cabinets or control racks—adds value to bulk install offerings.

pcb pluggable terminal block connector

A terminal block that mounts on a printed-circuit board and allows plug-in wire harnesses; suits telecom, automation and signal control modules which wholesalers distribute in volume.

screw terminal block connector right angle

A right-angle terminal block with screw clamps, useful for compact electrical cabinets where space is constrained and distributors seek space-saving solutions.

removable terminal block screw connector

A terminal block with screw connections that can be detached for maintenance; allows system integrators to replace modules easily and supports efficient servicing.

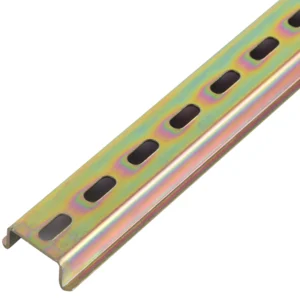

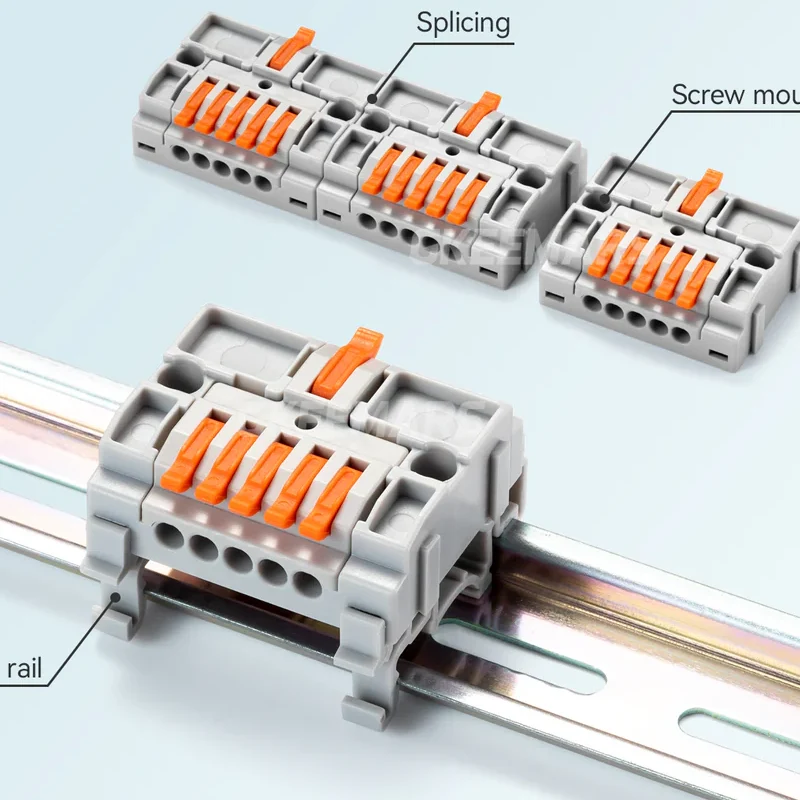

din rail terminal block connector

Terminal blocks designed for mounting on standard DIN rails (e.g., in control cabinets), simplifying installation and stock-keeping for panel-builders and resellers.

Terminal Block Connector By Electrical / Power / Industrial Applications

electrical terminal block connectors

General category of terminal blocks for electrical service—wholesalers value a broad series that covers control, distribution and signal wiring.

power terminal block connector

Heavy duty terminal block engineered for higher current and voltage applications in power panels and large control cabinets—adds margin for distributors targeting industrial customers.

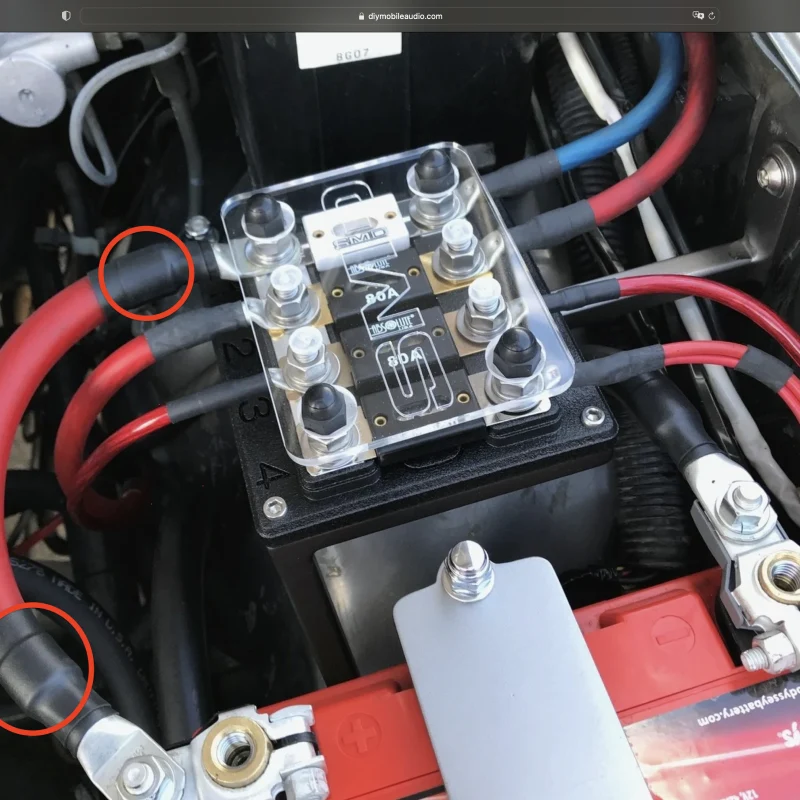

automotive terminal block connector

Terminal block built for automotive-grade vibration, temperature and environmental resistance, suitable for EV charging stations or vehicle integration—expands product range for wholesalers.

battery terminal block connecto

Specialized block for battery systems, energy storage installations or UPS racks—bulk buyers in telecom/utility sectors recognise value in a reliable block for battery wiring.

dc terminal block connector

Terminal block specified for DC circuits (e.g., telecom, solar, base station power supply) with suitable voltage rating and clear labelling—enables distributors to serve emerging energy markets.

ceramic terminal block connector

Terminal block made with ceramic insulation, suited for high-temperature or furnace control contexts—allows system integrators to offer premium, niche solutions.

Terminal Block Connector By Material

plastic terminal block connector

Terminal block with plastic (thermoplastic) housing for cost-effective installations such as basic control cabinets—wholesalers appreciate a budget-friendly line with good performance.

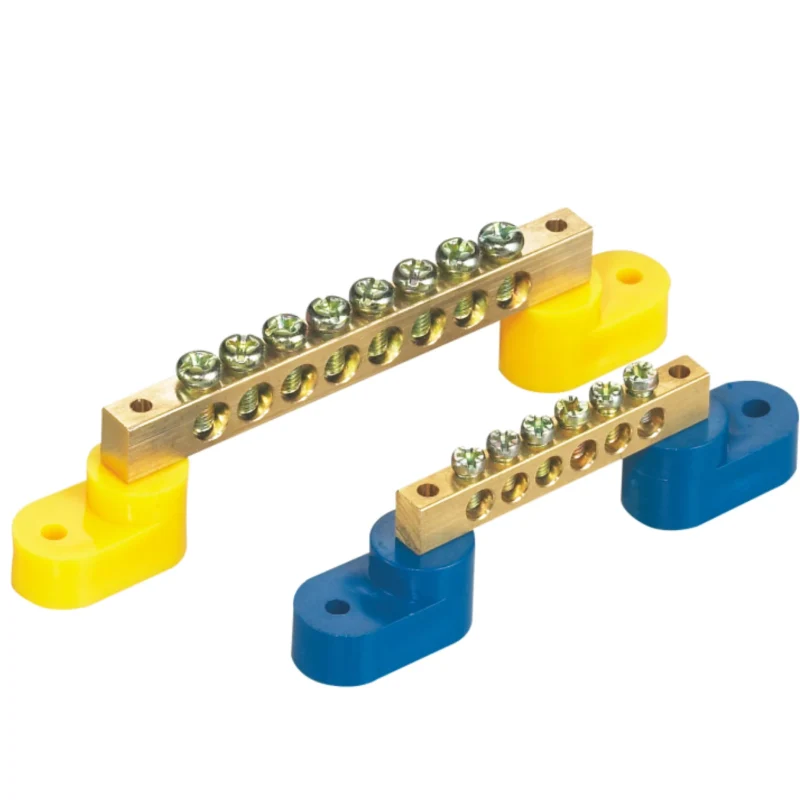

brass terminal block connector

Terminal block using brass conductor parts for high conductivity and corrosion resistance—important for cabinet builders supplying telecom or outdoor signal enclosures.

pvc terminal block connector

Terminal block where housing uses PVC for insulation and cost control; attractive to distributors sourcing large volumes for budget-sensitive electrical cabinets.

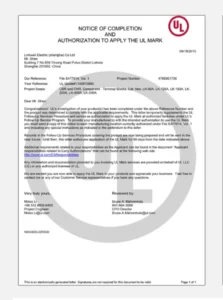

Certificate

Application of Terminal Block Connector in Different Industries

Telecom Base

Industrial Automation

Renewable Energy

Customize Your Terminal Block Connector

Cost Efficiency

We optimise material and production to reduce unit cost while maintaining industrial grade reliability—bulk buyers save.

Longer production runs mean lower set-up cost per piece and better margins for distributors.

Localised sourcing and lean logistics shorten lead time and reduce inventory overhead for your business.

Technical Performance

We design our Terminal Block Connector with high conductivity metals and robust insulation suitable for control cabinets, telecom signal cabinets and electrical enclosures.

Stringent testing (thermal cycle, vibration, shock) ensures stable connection even in harsh environments—reducing failures for your end-users.

Clear technical data (current rating, voltage, temperature) simplifies your selection and installation, improving your service reputation.

Customisation & Branding

We allow custom pin counts, colour coding, laser-etch branding, packaging and barrel variants to suit your brand or client projects.

That flexibility gives you unique offerings to your clients rather than commodity parts—boosting your market differentiation.

You can order with your logo, unique packaging and specified lead times so your sales channels stay aligned with your brand promise.

Supply & Service Reliability

We commit to production schedules and have quality control systems to ensure on-time shipment and minimal defects.

Our customer support and spare-parts availability help you maintain continuity in your cabinet production or signal cabinet manufacturing.

As a manufacturing partner focused on bulk and custom orders, we align with your business growth rather than small-scale retail mindset.

What are the Benefits of Terminal Block Connector ?

They simplify wiring in control and signal cabinets by providing clear, modular connection points; this reduces installation time and lowers labour cost.

They enhance safety and reliability by securing wires, preventing loose connections, and offering high electrical and mechanical performance in demanding industrial environments.

They support scalable distribution and maintenance workflows for wholesalers and system integrators by providing standardised modules, easy replacement and documented specifications.

Customer Testimonials

FAQ of Terminal Block Connector

What is a Terminal Block Connector and where is it used?

A Terminal Block Connector is an electrical interconnection device used to join wiring inside control cabinets, switchgear, telecom signal enclosures or electrical boxes. It securely holds wires, provides clear connection points, and simplifies wiring changes or maintenance. For wholesalers and OEMs, choosing the right terminal block means easier wiring, cleaner installations and fewer service issues.

How do I select the right current rating for a Terminal Block Connector?

You should match the connector’s rated current and voltage to your application’s maximum load plus safety margin. Consider ambient temperature, wire cross-section, number of conductors and terminal block pitch. Over-rating gives you margin for future expansion, lowers heat rise and improves longevity. Choosing an undersized part risks failure, downtime and costly warranty issues.

What materials are Terminal Block Connectors made of and why does that matter?

Typically the conductive parts use copper or tin-plated brass for good conductivity and corrosion resistance. The insulation housing uses polyamide, phenolic or thermoplastic rated for required temperature and fire class. Choosing quality materials ensures safe operation inside control cabinets and signal enclosures, meeting industrial standards rather than lower-cost consumer grade parts.

Can Terminal Block Connectors handle vibration and harsh industrial environments?

Yes — quality terminal blocks are designed for industrial use: they include strong clamps, secure wire retention, and housings resistant to vibration, dust and heat. For control cabinet or telecom signal cabinet use, they must meet relevant standards (e.g., IEC/EN series). Specifying a part rated for shock and vibration protects you from wiring failures and service interruptions.

How important is the wiring pitch and modular design for Terminal Block Connector?

Wiring pitch (distance between terminals) affects how many conductors fit, how compact the installation is, and how easy it is to trace wiring. Modular design allows you to add, remove or label blocks easily. For panel builders and wholesalers, choosing a flexible modular system means you can streamline stock and adapt to different projects quickly.

What to check for during installation of a Terminal Block Connector?

Ensure that proper torque is applied to securing screws, wire insulation is stripped correctly, conductor ends are neat and clean, and there’s no damage to the housing. Adequate labelling and isolation between potentials is important. Correct installation prevents loose connections, overheating, arcing and helps maintain long-term reliability in your systems.

How can I ensure my Terminal Block Connector meets compliance and quality for bulk purchase?

As a buyer you should request certifications (e.g., UL, IEC, CE), review test reports (e.g., temperature rise, short-circuit rating), assess batch traceability and audit the manufacturing partner. For bulk supply you need consistent quality and reliable delivery — verifying these ensures you and your clients avoid service costs, rework or failures down the line.

How do you support after-sales or re-orders for Terminal Block Connector?

We maintain stock of key components, support re-orders with consistent part numbers, and provide spare-part options and drawings. As Linkwellelectrics, we act as your manufacturing partner, enabling you to scale, customise and repeatedly supply your distribution network with confidence.

All-in-one Terminal Block Connector Solutions for Your Project

Choosing us as your Terminal Block Connector supplier gives you threefold benefits. First, quality—we adhere to strict industrial standards and inspect every batch so you receive consistent performance. Second, delivery—we maintain stock and schedule production to meet your project timelines, reducing downtime and risk. Third, market insight—we understand the needs of OEMs, electrical cabinet makers and telecom integrators, helping you stay competitive with cost-effective yet premium solutions.