If you’ve ever wondered what is a electrical bus bar, you’re not alone. A bus bar is a solid conductor that helps you carry large amounts of electrical power within an electrical system. You’ll see an electrical bus bar inside Electrical Enclosure control cabinets, power panels, and even in cabinet air conditioners or distribution terminal blocks.

In a power distribution system, the bus bar connects multiple circuits, making sure energy flows smoothly and safely. You’ll find them everywhere, from data centers to factories, thanks to their reliability and efficiency. Linkewell delivers trusted solutions for all your power distribution needs.

Common places you’ll spot electrical bus bars include:

- Industrial control panels

- Data centers

- Renewable energy systems

- Commercial buildings

- Electric vehicles

Electrical Bus Bar Key Takeaways

- Electrical bus bars are metal strips that safely carry and distribute large electrical currents inside control panels and cabinets.

- Bus bars improve power efficiency by reducing energy loss and simplify wiring, saving space and making maintenance easier.

- Copper and aluminum are common bus bar materials; copper offers high conductivity, while aluminum is lighter and more cost-effective.

- There are solid, laminated, and flexible bus bars, each designed for different needs like high current, compact spaces, or vibration resistance.

- Proper installation and regular maintenance of bus bars ensure safety, reliability, and long-lasting performance in electrical systems.

What Is a Electrical Bus Bar

Electrical Busbar Definition

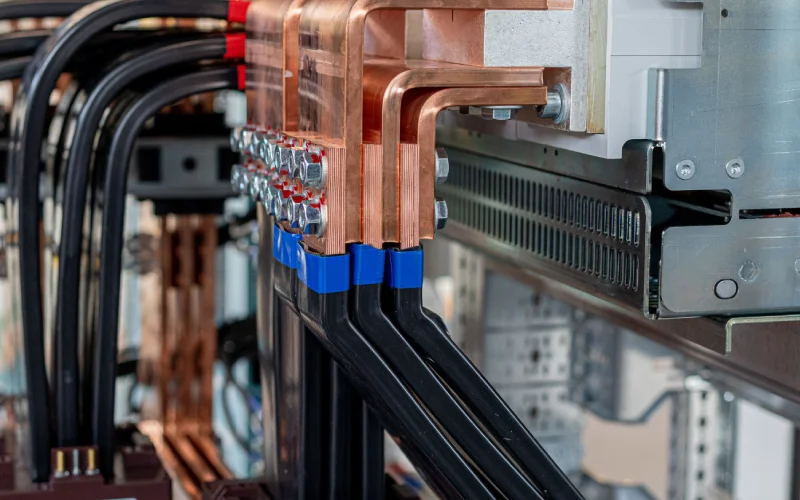

When you open an electrical cabinet or control panel, you might spot a thick metal strip or bar connecting different components. That’s the electrical bus bar. So, what is a electrical bus bar? It’s a metallic strip or bar—usually made from copper, aluminum, or brass—that carries high current and distributes power inside switchgear, panel boards, or enclosures. You’ll find electrical busbars in places like cabinet air conditioners, fan and filter units, and distribution terminal blocks.

International standards, such as IEC 60050 and IEC 61439, define a busbar as a rigid or flexible conductor designed to handle large amounts of electricity. These standards make sure busbar systems meet strict safety and performance requirements. The design of an electrical bus bar focuses on strength, heat dissipation, and the ability to connect to multiple circuits without extra joints. This setup helps you keep your power distribution neat, reliable, and easy to manage.

Tip: Electrical busbars often stay uninsulated and get supported by insulated pillars. This design lets them cool down quickly and makes it easy to tap into the power at different points.

Main Functions

You might wonder why you need a bus bar in your electrical system. The answer is simple: electrical bus bars make power distribution safer, more efficient, and easier to maintain. Here’s how they help you:

- Act as the main conductor, distributing large currents from one source to many circuits.

- Provide a low-resistance path, which means less energy loss and better efficiency.

- Simplify wiring by reducing the mess of cables inside your cabinet or control panel.

- Improve safety by consolidating grounding and lowering the risk of voltage drops.

- Make maintenance and troubleshooting easier with clear, accessible connection points.

- Save space and cut down on installation time compared to traditional wiring.

- Support modular layouts, so you can expand or change your system as your needs grow.

Let’s look at how busbar systems compare to traditional wiring:

| Cost Factor | Traditional Wiring (Cable) | Bus Bar System |

|---|---|---|

| Material Cost | Lower initial cost | Sometimes higher upfront cost |

| Installation | Labor-intensive, takes longer | Faster, less labor needed |

| Space Utilization | Needs more space for trays and wires | Compact, saves valuable space |

| Modifications | Disruptive and costly | Quick and easy to upgrade |

| Energy Efficiency | More voltage drop, higher losses | Lower voltage drop, better savings |

| Maintenance | Frequent repairs, complex | Durable, easy to inspect |

| Total Cost | Higher over time | Lower over the system’s lifetime |

You’ll see electrical busbars in all sorts of applications—industrial control panels, telecom cabinets, solar power systems, and even electric vehicles. Their modular design means you can add new circuits or tap-off boxes without shutting down your whole system. This flexibility makes busbar systems perfect for growing businesses or changing technology needs.

Note: Using a bus bar system in your cabinet air conditioner or distribution terminal blocks can help you save space, reduce heat, and keep your power distribution organized.

Electrical bus bar systems also help you cut long-term costs. They install quickly, need less maintenance, and make future upgrades simple. Their robust design means fewer repairs and less downtime. Plus, their efficient power handling reduces energy loss, which saves you money on your electric bill.

If you want a power distribution setup that’s safe, reliable, and ready for the future, electrical busbars are the way to go.

How Busbars Work

Working Principle

When you open up an electrical cabinet or control panel, you’ll often see a thick metal strip running through the middle. That’s the electrical bus bar, and it’s the backbone of your power distribution. The main job of a bus bar is to collect electricity from incoming feeders and distribute it to multiple outgoing feeders. You can think of it as a central highway for electrical current, making sure every device and circuit gets the power it needs.

A bus bar system uses a solid conductor—usually copper or aluminum—to handle high amp and voltage loads. The large surface area of the electrical bus bar keeps current density low, which means less resistance and less heat. This design helps you avoid voltage drops and power loss, even when your system is running at full amp capacity. You’ll find this especially useful in places like fan and filter units, cabinet air conditioners, and distribution terminal blocks, where reliable power delivery is critical.

Here’s what happens inside a busbar system:

- The electrical bus bar collects current from the main power source.

- It distributes that current evenly to all connected circuits or devices.

- The solid, open structure of the bus bar system allows heat to dissipate quickly, preventing overheating.

- Protective enclosures or elevated mounting keep the bus bar safe from accidental contact and physical damage.

Tip: By using a bus bar system, you can replace a tangled mess of wires with a single, organized conductor. This not only makes your electrical connections safer but also simplifies maintenance and future upgrades.

The electrical bus bar ensures that every part of your electrical system receives stable voltage and balanced loads. This uniform power distribution is key for sensitive equipment and helps you avoid unexpected shutdowns or failures. In modern electrical busbars, you’ll often see both insulated and non-insulated designs, depending on the safety requirements of your application.

Materials and Design

The material you choose for your bus bar system makes a big difference in performance, cost, and sustainability. Most electrical bus bars use either copper or aluminum. Each material has its own strengths, and your choice depends on your specific needs.

Let’s break down the most common options:

- Copper:

You get the highest electrical conductivity with copper. It handles high amp loads with ease and resists heat well. Copper is easy to process and solder, making it a favorite for demanding electrical busbar systems in industrial power distribution. However, copper costs more and can oxidize on the surface, which may reduce conductivity over time. - Aluminum:

Aluminum is much lighter than copper and costs less. It has good corrosion resistance because of its natural oxide layer. While it doesn’t conduct electricity as well as copper (about 60% of copper’s conductivity), it works great in systems where weight and budget matter more than maximum performance. You’ll often see aluminum bus bars in large control cabinets or where space and weight are at a premium.

Here’s a quick comparison to help you decide:

| Property | Copper Busbar | Aluminum Busbar |

|---|---|---|

| Electrical Conductivity | Very high (~58 MS/m) | Moderate (~37 MS/m), about 60% of copper’s |

| Weight (Density) | Heavy (~8.9 g/cm³) | Light (~2.7 g/cm³), about 70% lighter |

| Mechanical Strength | High tensile strength and rigidity | Softer, lower tensile strength |

| Corrosion Resistance | Stable, conductive oxide layer | Insulating oxide layer, needs special handling |

| Cost | Expensive, price-volatile | Cheaper, more price-stable |

| Ease of Fabrication | Easy to solder and plate, heavier to cut | Easier to cut and drill, needs special welding |

The design of your bus bar system also affects how much current it can carry and how well it manages heat. Copper busbars can handle higher currents with less temperature rise, while aluminum busbars need a larger cross-sectional area to carry the same current. The shape and spacing of the bus bar, as well as how you mount it, all play a role in heat dissipation and reliability.

If you’re working with a cabinet air conditioner or a distribution terminal block, you want a busbar system that fits your space and handles your amp requirements. Good design means you get efficient power delivery, less risk of overheating, and a longer lifespan for your electrical system.

Note: Aluminum bus bars are also a smart choice if you care about sustainability. Aluminum is highly recyclable and uses much less energy to recycle than copper. This makes it a greener option for eco-friendly projects.

Modern electrical busbars come in many shapes and sizes. You’ll find solid, laminated, and flexible designs, each tailored for specific applications. The right bus bar system gives you safe, reliable, and efficient electrical connections, whether you’re powering a small control panel or a massive industrial setup.

Types of Bus Bar

Solid Busbar

You’ll see solid busbars in almost every electrical cabinet or control panel. These busbars use flat, rigid strips of metal—usually copper or aluminum—to carry high amp loads. Solid copper busbars are especially popular because they offer excellent conductivity and resist corrosion. You get a tough, durable solution that stands up to both electrical and mechanical stress.

Here’s a quick look at what makes solid busbars special:

| Feature | Details |

|---|---|

| Material | Copper or aluminum |

| Shape | Flat, rigid strips or bars |

| Current Capacity | Handles high amp loads with low resistance |

| Heat Dissipation | Good, keeps your system cool |

| Applications | Switchgear, bus ducts, power panels, renewable energy, grounding points |

You’ll find solid busbars inside fan and filter units, cabinet air conditioners, and distribution terminal blocks. They keep your power distribution simple and reliable.

Tip: Solid busbars work best when you need a strong, straightforward path for lots of current.

Laminated Busbar

Laminated busbars take things up a notch. They use layers of conductive material, separated by insulation, all pressed together. This design reduces voltage drops and electrical noise, making your system more efficient and reliable. Laminated busbars also help you save space, thanks to their compact, stackable structure.

Why choose laminated busbars? Here are some reasons:

- Lower voltage drop and less electrical interference

- Better heat dissipation and thermal management

- Neat, compact installation—great for tight spaces

- Direct connection to power supplies and circuit boards

- Improved reliability and easier installation

You’ll often see laminated busbars in high-tech control cabinets, data centers, and industrial automation. They work well in places where you need to handle lots of amp and want to avoid wiring mistakes.

Flexible Busbar

Sometimes, you need a busbar that bends and twists to fit your setup. That’s where flexible busbars come in. These busbars use thin layers of copper or aluminum, wrapped in flexible insulation. You can bend them around corners or squeeze them into tight spots without losing performance.

Flexible busbars shine in situations where space is limited or vibration is a concern. For example, you might use them in electric vehicle batteries, renewable energy systems, or machinery that moves or shakes. They absorb shock and vibration, so your connections stay safe and secure.

Note: Flexible busbars make installation easier in complex layouts, especially inside crowded electrical cabinets or control panels.

Electrical Bus Bar Applications

Power Distribution Panels

You see bus bar systems at the heart of every modern power distribution panel. These panels use laminated and multi-layer bus bars to keep your wiring neat and organized. The design includes molded-edge insulation, which protects the conductors and keeps everything safe. You get secure mounting with clinch hardware and anti-rotation tabs, so nothing shifts during operation. Pluggable connectors make installation and maintenance quick and easy. Copper bus bars, known for their high conductivity and thermal stability, help you manage large currents without overheating. This setup gives you reliable power delivery and stable voltage, even in demanding industrial environments. You find these panels in factories, data centers, and telecom rooms, where safe and efficient power distribution is critical.

Linkewell Power Distribution Block

If you need a compact solution for 12v applications or 12v power management, Linkewell’s Power Distribution Block stands out. This product uses a bus bar system to split a single electrical power source into multiple circuits. You get a clean, organized way to manage power inside control cabinets, electrical enclosures, and telecom signal cabinets. The block uses high-quality copper or brass conductors, which means you get minimal voltage drop and excellent heat dissipation. Its modular design lets you expand or reconfigure your setup as your needs change. You can count on UL and CE certifications for safety and reliability. This makes it perfect for automation, energy, and telecom industries that demand efficient power distribution solutions.

Recommended products

Electrical Power Distribution Box

You often find electrical power distribution boxes with integrated bus bar systems in places where space matters. These boxes work well for 12v applications, especially in control panels, data centers, and outdoor telecom cabinets. The flat, wide bus bars inside allow you to fit multiple power lines or phases in a small footprint. You get up to 99% energy efficiency, thanks to low electrical impedance and great heat dissipation. The modular design means you can add or change circuits quickly, which is ideal for projects with tight deadlines. Linkewell’s distribution boxes meet IEC and UL standards, so you know your electrical power system is safe and reliable. You see these boxes in industries like automation, medical, and alternative energy, where organized power delivery is a must.

Tip: If you want a scalable, safe, and efficient power distribution system for your 12v applications, look for solutions that use distribution bus bars. They make upgrades and maintenance much easier.

Busbar Installation and Safety

Use Shield Clamps Installation Tips

Getting your busbar installation right is the first step to a safe and reliable operation. You want to make sure every connection is tight and secure. Here’s a simple checklist to help you:

- Bolt and tighten all joints carefully. Use a torque wrench to match the manufacturer’s specs.

- Apply anti-oxidation compound on joints to prevent corrosion and keep electrical connections strong.

- Test for continuity and voltage drop after installation.

- Always follow local and national electrical codes.

- Have a licensed electrical engineer review your plans and load calculations.

- Use insulated tools and wear protective gear like gloves and safety glasses.

- Prepare cables with insulated cutters and use heat shrink tubing for extra insulation.

- Drill mounting holes precisely for proper alignment and stability.

- Double-check with a digital multimeter before powering up.

Tip: Most busbar failures happen at joints or stand-offs. Take your time with these steps to avoid future problems.

Safety Practices

You can’t overlook safety when working with busbars. Certified products and careful planning keep you and your equipment protected. Linkewell’s busbar solutions meet UL, CE, and IEC standards, so you know you’re getting top-notch safety. Here’s what to keep in mind:

- Always use busbars and accessories that carry certifications like UL 94V-0, IEC 61439, and CE.

- Check that insulation materials are flame-retardant and halogen-free.

- Maintain minimum approach distances to reduce arc flash risk.

- Wear insulated gloves, safety glasses, and protective clothing.

- Inspect mounting surfaces and align insulators before installation.

- Use calibrated tools to avoid overtightening bolts.

- Follow manufacturer guidelines for torque and fastening.

| Standard/Certification | What It Means for You |

|---|---|

| UL, CE, IEC | Global safety and quality compliance |

| RoHS | No hazardous substances |

| UL 94V-0 | Flame-retardant insulation |

Note: Linkewell’s products go through strict quality checks and hold multiple international certifications, so you can trust their safety in your control cabinets, fan and filter units, and distribution terminal blocks.

Maintenance

Regular maintenance keeps your busbar system running smoothly and extends its life. Here’s how you can stay ahead:

- Inspect all ground connections for corrosion or looseness.

- Clean busbars to remove dust and oxidation.

- Test grounding resistance with a tester.

- Replace damaged or worn parts right away.

- Watch for warning signs like heat, burn marks, buzzing sounds, or flickering lights.

- Use thermal imaging to spot hot spots and voltage drop tests to find weak points.

- Check insulation and reapply conductive grease on aluminum busbars as needed.

Keeping up with these tasks helps you avoid downtime and ensures safe and reliable operation for years.

If you want a custom, safe, and efficient busbar solution, reach out to Linkewell. Their team can help you choose the right setup for your cabinet air conditioner, fan and filter, or distribution terminal blocks. You’ll get expert support and products that meet the highest safety standards.

Electrical bus bars keep your power distribution efficient and reliable, whether you work with cabinet air conditioners, fan and filter units, or distribution terminal blocks. Take a look at how they boost performance and safety:

| Aspect | Impact on Power Distribution |

|---|---|

| Materials | High conductivity, less power loss |

| Thermal Performance | Prevents overheating, improves safety |

| Design Advantages | Modular, compact, easy to expand |

Choosing certified solutions like Linkewell ensures you get top safety and long-lasting results. For the best outcome, talk to experts who understand your needs.

FAQ

What is a electrical bus bar used for in control cabinets?

You use a bus bar in control cabinets to connect and distribute power to different devices. It keeps wiring neat and makes your system safer. You often see them in fan and filter units or cabinet air conditioners.

How do I choose the right bus bar material?

Pick copper for high conductivity and durability. Choose aluminum if you want something lighter and more affordable. Both work well in distribution terminal blocks and electrical cabinets.

Can I customize a bus bar for my project?

Yes, you can! Many suppliers, like Linkewell, offer custom bus bars. You get the right size, shape, and material for your cabinet, control panel, or distribution block.

How do I maintain a bus bar system?

Check for loose connections and signs of corrosion. Clean dust from the bus bar and surrounding parts. Regular inspections keep your cabinet air conditioner and terminal blocks running smoothly.

Are bus bars safe for use in harsh environments?

Absolutely. When you use certified bus bars with proper insulation, they handle dust, moisture, and heat. Products from Linkewell meet strict safety standards for tough industrial settings.

Conclusion

Electrical bus bars make your power distribution simple, safe, and efficient. You find them in control cabinets, fan and filter units, and terminal blocks. Choose certified, high-quality solutions for the best results. If you want a custom setup or expert advice, reach out to Linkewell. You get reliable products and support for every project.