You may ask, what is a screw terminal and why is it important in electrical wiring? A screw terminal helps you attach wires tightly. This gives you strong electrical connections. It stops wires from coming loose or getting rusty. Using screw terminals in your wiring lowers the risk of short circuits. It also helps prevent open connections and heat that can start fires. Screw terminals are important because they stop many common safety problems in electrical wiring. Linkewell makes good screw terminals. Professionals trust them for safe and easy wiring everywhere.

Screw Terminal Key Takeaways

- Screw terminals hold wires tightly. This makes electrical connections safe and strong. Tight wires help stop fires and keep wires from coming loose.

- They work by pressing bare wires under a screw. The screw holds the wire in place. You do not need to use solder. This makes wiring simple to put in and fix.

- Screw terminals are used in control panels, HVAC systems, and telecom boxes. They can work with many kinds and sizes of wire.

- There are two main types. Barrier strips are for simple wiring. Modular blocks are for systems that need to grow or change.

- You should check and tighten screws often to keep things safe. Pick certified, high-quality terminals like Linkewell for good, long-lasting use.

What Is a Screw Terminal

Definition and Function

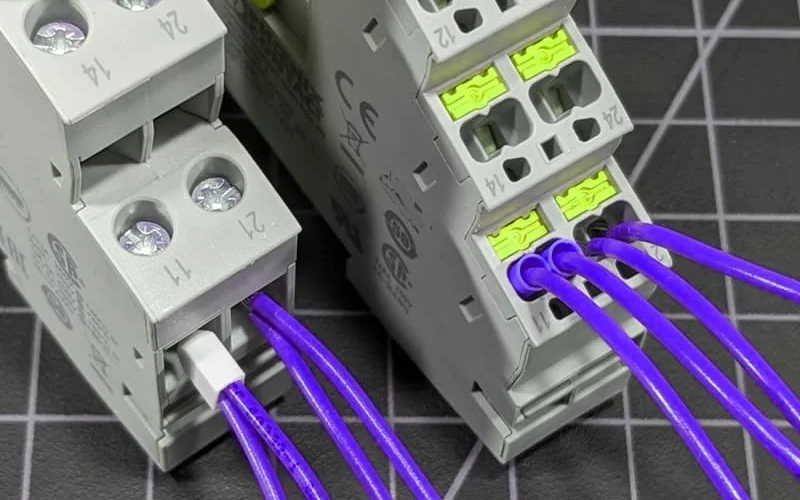

You might ask, what is a screw terminal? It is a connector for electrical wires. It lets you join wires so they stay together. You put a stripped wire under a screw or clamp. Then you turn the screw to hold the wire tight. This makes a strong connection for electrical wiring. You can use a flat-blade or cross-blade screwdriver to do this. Sometimes, you might need a hex key or Torx key, depending on the screw.

Screw terminals work by holding the wire tightly. This keeps the wire from slipping out or losing contact. You can put the wire in directly or use a ferrule or connecting lug for more support. The screw pushes down on the wire or a metal plate. This keeps the connection firm. This design follows rules for electrical safety. It helps you make safe and reliable wiring in many places.

Screw termination is a simple way to connect wires. You do not need to solder anything. You can loosen or tighten the screw if you want to change the wiring. This makes screw terminals good for new setups and repairs. You get a strong connection that lasts, even if you need to fix it later.

Tip: Always tighten the screw just enough. Too much force can hurt the wire. Too little can make the connection weak.

Common Electrical Applications

You will see screw terminals in many wiring jobs. They are used in control cabinets, electrical panels, and telecom boxes. You can find them in HVAC systems, lighting circuits, and machines. These connectors help you keep wires neat in big systems.

Here are some common uses for screw termination:

- Control cabinets for industrial automation

- Electrical enclosures in commercial buildings

- Power distribution panels

- Telecom signal boxes and network equipment

- HVAC control systems

Screw terminal blocks let you connect many wires in one spot. You can use them to split power, join circuits, or link control signals. The modular design of a screw terminal block makes it easy to add or change wires as you need.

Screw terminals work with both solid and stranded wires. You can use them where you need to disconnect and reconnect wires often. The materials, like copper and brass, help the connection stay strong under different loads. Checking and tightening the screws often keeps your connections safe and reliable.

Screw termination is special because it gives you safety and flexibility. You can trust these connectors in many places, like factories and offices. When you pick the right screw terminal blocks, you make your wiring safer and easier to handle.

How Screw Terminals Work

Clamping Mechanism

When you use screw terminals, you count on a simple clamping system. You put a stripped wire inside the terminal and turn the screw. The screw pushes the wire against a metal channel. This makes a connection with very little resistance. The screw spreads pressure evenly, so the wire stays tight. It will not come loose, even if things shake or get hot or cold.

- The screw terminal uses strong metals like copper or brass for the parts that carry electricity. These metals keep resistance low and the connection strong.

- Some screw terminals have wire guards or tension sleeves. These parts spread out the pressure and protect the wire strands from harm.

- Some advanced types use a tapered mandrel or a cone-shaped spike. This shape pushes the wire strands outward. It makes the contact more stable and reliable.

The outside of the terminal is often made from tough polyamide plastic. This plastic stands up to heat, aging, and rust. It also slows down fire, which helps keep your system safe. The metal parts have special coatings to stop rust. This helps your connections last longer, even in hard places.

Creating Reliable Electrical Connections

You want your electrical connections to stay safe and steady for a long time. Screw terminals help by making gas-tight contact points. When you tighten the screw, you press the wire into the metal channel. This keeps out air and water, so the wire does not rust. Your connection stays strong and keeps its low resistance.

Screw terminals work with both solid and stranded wires. The clamping system fits different wire sizes, so you always get a tight connection. The screw locking system keeps the terminal from coming loose, even if the equipment shakes or gets hot. You can trust screw terminals to last through many times of connecting and disconnecting.

Tip: Always check your screw terminals when you do regular maintenance. Tighten any loose screws to keep your electrical connections safe and strong.

Screw terminals give you safe electrical connections in control cabinets, panels, and other systems. You can make a connection fast, without soldering. This makes them a great choice for anyone who needs safe and strong electrical connections in factories or businesses.

Types of Screw Terminal Blocks

Barrier Strips

Barrier strips are a very common type of screw terminal block. You use them when you need to connect big wires or strong circuits. Each wire goes under its own screw and is kept apart by plastic. This design keeps wires safe and stops short circuits from happening. You often see barrier strips in control panels at factories. They help you keep screw termination neat for power and control wiring. Using barrier strips is a simple and cheap way to connect wires. These screw terminal blocks are good for basic wiring jobs.

Modular Terminal Blocks

Modular terminal blocks give you more choices. You can add or take away these screw terminal blocks as your system changes. Each block sits on a DIN rail, so you can build what you need. Modular terminal blocks work with different screw terminations, like screw, spring, and push-in. You can use them for tricky control systems and machines. These blocks make fixing things easy. You can separate circuits, test wires, and change parts fast. Modular terminal blocks help you keep your wiring neat and safe.

Tip: Modular screw terminal blocks let you grow your system without changing all the wires.

Here is a table to help you see the differences between barrier strips and modular terminal blocks:

| Aspect | Modular Terminal Blocks | Barrier Strips (Terminal Strips) |

|---|---|---|

| Structure | Modular, single units on DIN rails | Fixed, one-piece rows |

| Modularity | High; you can add or change them | Low; set number of terminals |

| Features | Many clamping types, special uses, extra parts | Basic screw-down, simple cover |

| Safety | Better insulation, higher safety ratings | Basic insulation, lower safety ratings |

| Cost | Higher, more features | Cheaper |

| Application | Hard control, automation, flexible wiring | Simple wiring, power sharing |

| Maintenance | Easy to find and fix circuits | Medium, not as easy to use |

- Modular terminal blocks help you make your system bigger.

- You can change and fix wiring easily.

- These blocks let you repair things fast and save time.

Linkewell Screw Terminal Features

When you pick Linkewell screw terminal blocks, you get strong products made from tough materials. These screw terminal blocks have certifications like UL, CE, CCC, and ROHS. UL means the product is safe for North America. CE shows it meets European safety and environment rules. CCC and ROHS give extra safety and eco-friendly proof. Linkewell screw terminal blocks work with both solid and stranded wire. The modular design lets you make your system bigger if you need to. You get a tough, long-lasting answer for all screw terminations. These screw terminal blocks give you safe screw termination, even in hard factory places.

Advantages of Screw Terminals

Safety and Reliability

You want your electrical connections to be safe and work well. Screw termination helps you feel sure about this. When you tighten screw terminals just right, wires stay in place. This stops wires from getting loose and causing heat or fires. If you tighten too much, you can hurt the wire or threads. Always follow what the manufacturer says. Checking and tightening screws often keeps your system working well. Many screw terminals now have plug-in designs and locks. These features stop wires from slipping out by mistake. You can trust screw termination for safety if you install and care for it the right way.

Tip: Check your screw terminals every few months. Look for rust or wire damage early.

Versatility in Electrical Systems

Screw termination works in many electrical systems. You can use screw terminals in homes, factories, and cars. They also work in places with lots of shaking. The wires stay tight, so they do not come loose. If you need to move or change wires, screw terminals make it simple. You can use them again and again, which saves time and money. Systems that need repairs or changes often use screw termination. Safety-focused jobs also pick screw terminals because they meet strict rules and keep things safe.

- Screw terminals work in control panels, HVAC systems, and telecom boxes.

- They are good for places where you connect and disconnect wires a lot.

- Screw termination helps keep your wiring neat and tidy.

Linkewell Product Benefits

When you pick Linkewell screw terminals, you get more benefits. The materials fight fire and rust, so your connections last longer. Linkewell tests its products in hot and wet places, so you know they are strong. The screw terminals meet UL508A and IEC61439 standards. This means they are safe and work well in factories. If you take care of them, Linkewell screw terminals can last over 10 years. You get a strong hold, a long life, and peace of mind for your projects.

Linkewell’s screw terminals give you safety, flexibility, and strong performance in tough places.

How to Use Screw Terminals

Installation Steps

You can put in screw terminal blocks if you follow steps. First, turn off all power in the area. Strip the wire so some bare metal shows. Make sure the bare part fits under the screw. Put the wire into the terminal opening. Use a screwdriver to tighten the screw. Stop when the wire feels tight and does not move. Use a torque tool so you do not make it too tight or too loose. This keeps the connection safe and stops damage. You can use heat shrink tubing or sealing grease for extra safety. These help keep out water. Linkewell gives clear guides and expert help if you need it.

Choosing the Right Terminal

Picking the right screw terminal blocks helps keep wiring safe. You should:

- Check how much current your system needs. Pick a terminal block with an amp rating that is high enough.

- Make sure the terminal block fits your wire size. If you use the wrong size, it can get hot and not work well.

- Think about heat and moisture in your area. Pick blocks with good insulation and that do not rust if needed.

- Plan for changes later. Pick terminal blocks with a higher amp rating if you may add more load.

- Think about what you will connect, like motors or lights. This can change what you need.

- Always follow the maker’s rules and safety codes. Linkewell’s team can help you pick the best screw terminal blocks.

Best Practices for Electrical Safety

You can keep your wiring safe by using these tips:

- Use a torque tool that is set right to tighten screws. This stops loose or broken connections.

- Do not make screws too tight. This can break the threads or crack the case.

- Keep screw terminal blocks dry with good sealing and materials that do not rust.

- Check connections often. Pull on wires to see if they stay in place.

- Use only good materials and follow the right steps to install.

- For outside or tough places, use screw terminal blocks that are waterproof and block UV rays.

Tip: Linkewell gives you clear instructions and support. This helps you keep screw termination safe and working well anywhere.

Screw terminals help you make safe and strong wiring. You can use them in many projects to keep wires secure. It is easy to check your connections when you use screw terminals. Here are some important things to know:

- Screw terminals work with many wire sizes and types.

- They use strong metals and safe covers for long-lasting wiring.

- Certified screw terminals, like Linkewell’s, follow top safety rules.

| Feature | Benefit |

|---|---|

| Fire resistance | Safer wiring in hard places |

| Waterproof design | Good wiring for outside use |

Pick certified and tough screw terminals for your next wiring job.

FAQ

What is a screw terminal used for?

You use a screw terminal to connect wires in electrical systems. It helps you make safe and strong connections in control panels, machines, and telecom boxes.

Can you reuse screw terminals?

Yes, you can reuse screw terminals. You just loosen the screw, remove the wire, and insert a new one. This makes changes and repairs easy.

How do you choose the right screw terminal?

You should check the wire size and current rating. Pick a screw terminal that matches your needs. Always follow safety rules and ask experts if you are not sure.

Are screw terminals safe for outdoor use?

Many screw terminals have flame-retardant and corrosion-resistant materials. Some models work well outdoors. Always check the product details before using them outside.

How often should you check screw terminals?

You should check screw terminals during regular inspections. Look for loose screws or signs of wear. Good maintenance of screw terminal blocks keeps your system safe and reliable.