When it comes to protecting electrical components, understanding NEMA ratings is crucial. These standards define how well enclosures resist dust, water, and more—ensuring safety, reliability, and long-term performance in demanding industrial environments. Let’s break it down.

NEMA Rating: Ensuring Reliable Electrical Enclosures

When we talk about NEMA Rating, we’re tapping into a cornerstone of industrial safety and protection. This article dives into what NEMA standards are, why they make a difference in your electrical cabinets, and how our expertise in accessories—like fans, cabinet air conditioners, terminal blocks, and temperature controllers—ensures compliance, durability, and user satisfaction.

What Is NEMA Rating?

Origin and Authority of NEMA

Back in 1926, the National Electrical Manufacturers Association (NEMA) was established as the go-to U.S. trade association for electrical equipment manufacturers.NEMA’s mission? To guarantee safety, standardization, and innovation. While NEMA itself doesn’t physically test products, it sets rigorous performance criteria reflected in NEMA 250, with independent labs like UL and CSA certifying conformity.

How NEMA Ratings Work

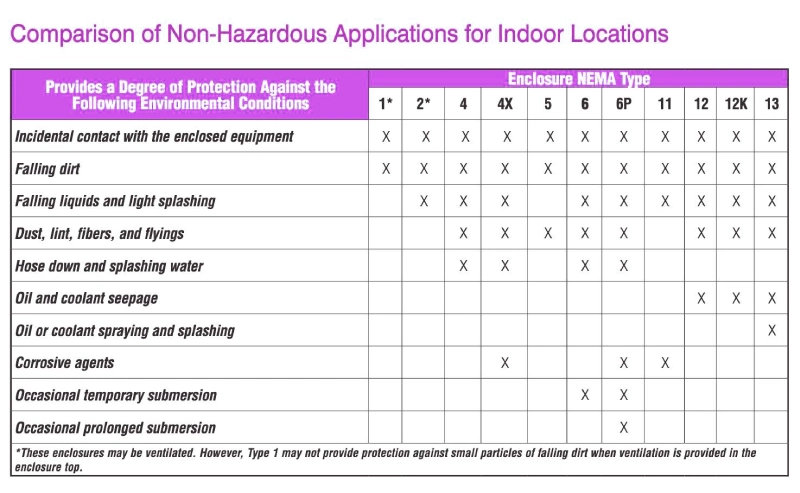

Ratings such as Type 1 through 13 reflect how well an enclosure resists dust, water, ice, corrosion, and even hazardous atmospheres. Each type has clearly defined scenarios—from everyday indoor cabinets to explosion-proof housings. Think of it as a shorthand for specifying exactly how tough and suitable your electrical housing needs to be.

Why NEMA Ratings Matter in Electrical Cabinets

Environmental Protection

Inside an industrial cabinet, the atmosphere could vary greatly—dust in processing plants, moisture in HVAC rooms, heavy washdown areas in food processing, or oily mist in machining shops. NEMA levels help you select accessories that match these environments, preventing dust ingress, water damage, or corrosion.

Safety for Personnel and Equipment

Beyond protecting components, NEMA ratings guard people. A poorly rated enclosure could lead to electric shock, arc-flash risk, or internal failures. Our commitment is to build parts that ensure both component integrity and user safety—even under harsh industrial conditions.

Detailed NEMA Rating Breakdown

NEMA 1 & 2 (Indoor Use)

- Type 1: Basic indoor protection—guards against dust and incidental contact.

- Type 2: Adds limited dripping or light water protection

NEMA 3, 3R, 3S, 3X Series (Outdoor/Weather)

These standards extend protection outdoors, from rain and sleet to windblown dust. Variants like X offer corrosion resistance; S ensures mechanisms work even in icing

NEMA 4 & 4X (Washdown/Corrosion Protection)

Rated for washdown areas—waterproof to hose streams and resistant to freezing. Type 4X also resists corrosion, ideal for chemical or salty environments .

NEMA 5 to 6P (Dust- and Water-Resistant)

- Type 5: Dust-tight, indoor only.

- Types 6 & 6P: Protects against hose-directed water and temporary to prolonged submersion

Hazardous‑location Series (7, 8, 9, 10)

Designed to prevent explosions in flammable or dust-prone environments. Includes Mine Safety (MSHA) ratings under Type 10

Automation & IP Code Cross‑Reference

NEMA ratings loosely align with IEC IP codes—Type 4 equals IP66/68, Type 5 matches IP53, Type 6 is roughly IP67, etc. But NEMA adds icing, corrosion, knock-outs, and mechanical access tests.

How We Leverage NEMA Expertise in Our Cabinet Accessories

Recommended products

Industrial Fans & Cooling Integration

Fans are selected and certified based on NEMA level—Type 4/4X fans go into washdown zones, while NEMA 12 fans meet oil and dust-room specs. Fans integrate with thermal switches and thermostats to dynamically manage heat during summer or cold snaps.

Terminal Blocks, Temperature Controls & Air Conditioning

Recommended products

Our terminal blocks, thermostats, and cabinet AC units are all designed to NCC/UL and match NEMA requirements. For instance, a Type 4X cabinet uses stainless-steel or aluminum AC condensing units to prevent corrosion and maintain enclosure integrity.

Engineering Standards and Best Practices

We engineer with IEEE, NEC, NFPA, and MSHA standards in mind. For example, NEC mandates certain cable knock-outs and ground conductor spaces. We include these in our assemblies to ensure both compliance and easy installation.

Real‑World Feedback from Distributors and End‑Users

Wholesale Partner Praise

A prominent U.S. wholesaler remarked:

“Your NEMA‑rated fans and terminal blocks are a cut above—reliable, easy to install, and sell themselves with their specs.”

Terminal‑Customer Case Studies

One food processing plant shared:

“After switching to your Type 4X cooling units, we saw zero corrosion issues in six months—even after daily sanitary washdowns.”

Ensuring Compliance & Quality

UL/CSA, NEC, NFPA, and MSHA Standards

We test components via UL/CSA accredited facilities and design per NEC Articles 312, 400, 501–508, and MSHA Part 18. Each piece is traceable, certifiable, and lab-approved.

ISO/IEC IP Code Comparison

While IP66 means ingress protection withstanding high-pressure water jets, NEMA 4/4X also requires internal icing and corrosion tests. So we deliver double-checked reliability beyond IP codes NEMA.

Technical Insights and Strategies

Cooling Efficiency in High IP Series Cabinets

High-rating cabinets retain heat. Adding thermostats with variable-speed fans and filtered airflow paths ensures temperature control, prolongs equipment life, and reduces energy usage.

Material Selection for Corrosive Environments

Our Type 4X gear uses stainless steel or powder-coated aluminum, ensuring solid performance even in marine or chemical plants. We also optimize gaskets and coatings based on environment and CLEANING SOLVENT compatibility.

Where Are NEMA-Rated Enclosures Used?

Industrial Facilities

Factories and processing plants rely heavily on NEMA enclosures to protect sensitive electronics. In dusty environments like woodworking or metal shops, NEMA 12 or NEMA 13 enclosures keep airborne particles out. In wet or washdown zones like food and beverage production, NEMA 4 or 4X boxes are a must to handle high-pressure cleaning.

Outdoor Installations

Power systems, lighting controls, and telecommunications equipment often sit outside, exposed to rain, snow, and wind. NEMA 3R and 4 enclosures are commonly used in these settings because they provide solid defense against the elements. NEMA 3S, 3SX, and 4X go further by handling corrosion and icing—making them ideal for coastal and high-altitude installations.

Oil, Gas, and Hazardous Environments

Explosive gases and dusts in petrochemical plants and mining operations demand specialized enclosures like NEMA 7, 8, 9, and 10. These are engineered to contain potential explosions and prevent outside sparks or gases from triggering hazardous events. It’s about life-or-death safety, not just performance.

Water and Wastewater Treatment Plants

These facilities are full of moisture and chemicals. NEMA 4X enclosures with stainless steel or non-metallic bodies are common here, offering high corrosion resistance. Control systems, sensors, and relays in these plants need that rugged layer of protection.

Agriculture and Irrigation Systems

In dusty, wet, or pest-prone environments like farms or greenhouses, NEMA-rated enclosures protect pumps, valves, and sensors. From barns to pump stations, NEMA 3 or 4 units keep gear running despite the challenges of the field.

Marine and Coastal Applications

Seawater is no joke—it corrodes fast. NEMA 4X stainless steel enclosures are used on ships, docks, and ports to keep electronics functioning without rusting away. These units often include cooling fans and salt-resistant gaskets.

Commercial Buildings and Rooftops

NEMA enclosures on rooftops or building exteriors house HVAC controls, backup generators, and lighting timers. Even signage systems use NEMA boxes to ensure uninterrupted operation, rain or shine.

FAQ

- What steel type is best for Type 4X cabinets?

Stainless steel (304/316) or powder-coated aluminum—depending on chemical exposure. - Can IP66 components be swapped into a NEMA‑rated cabinet?

Usually yes, but NEMA certification may still require sealing, corrosion resistance, and other criteria. - Do NEMA ratings cover ice and snow?

For types like 3S/3SX/4X, yes—they must operate even when ice‑covered. - How long is Type 6P submersion tested?

It must withstand continuous water exposure for a specified duration—refer NEMA 250 for exact specs (e.g., hours at a depth). - Does installing a cabinet AC void ratings?

Not if the unit and mounting meet NEMA standards; our screws and seals ensure rating is maintained. - Are NEMA accessories UL‑approved?

Yes—our fans, blocks, and sensors are UL/CSA certified and traceable.

Conclusion

NEMA ratings aren’t just industrial jargon—they’re promises of safety, reliability, and performance. When designing cabinets that house fans, terminal blocks, thermostats, or AC units, matching NEMA specifications is essential. Our gear is engineered for real-world demands—from washdown areas to explosive atmospheres—and vetted by distributors and clients alike.

Bookmark this guide, share it with your engineering team, and turn to it when choosing components that won’t let you down. Choose NEMA. Choose durability. Choose peace of mind.

Contact us today to get professional-grade electrical cabinet products