You see cooling systems everywhere—at home, in offices, and across factories. Some names stand out in the market, like Johnson Controls Inc., which leads with HVAC systems and chillers built for energy efficiency. Evaporative cooling systems are also popular, especially in industries where excessive heat can damage equipment.

When you pick the right types of cooling systems, you protect your space and save on costs. Linkwell offers smart solutions for industrial and enclosure cooling, helping you keep things safe and reliable. Think about your needs and environment before choosing a cooling system.

Key Takeaways

- Central air conditioners provide even cooling for large spaces, making them ideal for homes and offices.

- Mini-split systems offer flexibility and energy savings, perfect for smaller or uniquely designed areas.

- Heat pumps deliver both heating and cooling, making them a smart choice for year-round comfort.

- Evaporative coolers are cost-effective solutions for dry climates, but they lose efficiency in high humidity.

- Linkwell’s enclosure cooling systems protect sensitive electronics, ensuring reliable operation and reducing downtime.

Recommended products

Types of Cooling Systems for Homes and Industry

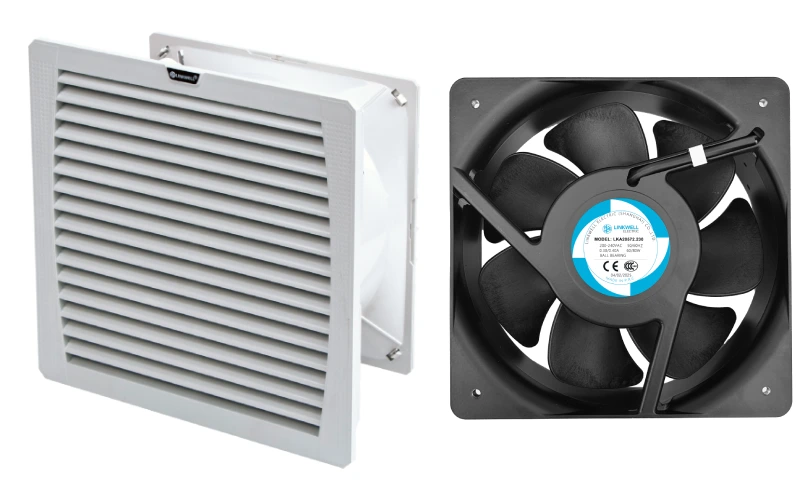

Electrical Cabinet Fan Overview

An electrical cabinet fan plays a vital role in keeping control cabinets, electrical enclosures, and telecom signal cabinets at a stable temperature. When your equipment runs for long hours, it naturally generates heat. If that heat is not removed in time, components can fail, sensors can malfunction, and your entire system may face unnecessary downtime. That’s why you see cabinet fans used in factories, automation lines, telecom base stations, power distribution cabinets, and communication cabinets. They protect sensitive electronics by moving hot air out and pulling cooler air in, ensuring a balanced airflow.

A reliable cabinet fan also helps extend the lifespan of electrical parts. When temperatures stay stable, PLCs, drives, transformers, relays, and control boards perform more consistently. This gives your clients fewer repair costs and more confidence in your solutions.

Another benefit is energy efficiency. Instead of using large cooling systems, many companies choose electrical cabinet fans because they save power while still offering very effective cooling. For wholesalers and distributors, cabinet fans are a strong repeat-order product, since every new cabinet installation requires ventilation and existing systems need regular upgrades.

Overall, an electrical cabinet fan is one of the simplest and smartest ways to protect industrial equipment, maintain stable performance, and improve long-term reliability.

When you look at the types of cooling systems available, you’ll notice that homes and industries use different designs to meet their needs. Let’s break down the main options you’ll find in both settings.

Central Air Conditioner Overview

If you want steady comfort at home or in a large office, a central air conditioner is a classic choice. This air conditioning system cools air in a central unit and pushes it through ducts to every room. You get even temperatures and better air quality. Most central air conditioners in homes have SEER2 ratings between 13.4 and 26, so you can pick a conditioner that matches your energy goals. In commercial spaces, central air conditioners handle big areas and keep temperatures consistent. You’ll see these conditioners on rooftops or tucked away in backyards. Homeowners can often handle basic maintenance, but commercial units need professional care.

Tip: Central air conditioners work best when you want to cool multiple rooms at once.

Mini-Split Systems Explained

Mini-split systems are a smart pick if you want flexibility. These ductless mini-split air conditioners don’t need ductwork, so installation is easier and cheaper—usually between $3,000 and $6,000. You can control temperatures in different zones, which saves energy. Mini-split units often have SEER ratings above 20, making them more efficient than many central air conditioners. Ductless mini-split systems also improve air quality since there are no ducts to trap dust. In small commercial spaces, mini-split conditioners offer heating and cooling, low maintenance, and easy installation. You’ll find ductless mini-split air conditioners in older buildings or places with tricky layouts.

| Benefit | Description |

|---|---|

| Energy Efficiency | Ductless mini-split air conditioners avoid energy loss and let you control zones. |

| No Ductwork, Easy Install | Mini-split conditioners are perfect for older buildings or unique layouts. |

| Low Maintenance | Ductless systems reduce allergens and lower upkeep costs. |

| Heating and Cooling Options | Many mini-split conditioners provide both heating and cooling. |

Heat Pumps and Their Uses

Heat pumps give you both heating and cooling in one system. You can use them in homes or industrial settings. Most heat pumps last 10 to 20 years if you keep them maintained. In cold climates, older heat pumps may struggle, but newer models handle extreme temperatures better. You’ll see heat pumps in places where you want year-round comfort and energy savings. Ductless mini-split heat pumps can last up to 30 years, so they’re a solid investment.

- Heat pumps work well for moderate climates.

- Modern heat pumps use advanced compressors for better performance.

- You can use heat pumps in homes, offices, or factories.

Evaporative Coolers for Dry Climates

Evaporative coolers, also called open-loop evaporative cooling systems, use water to cool air. These systems work best when humidity is below 30%. If humidity rises above 50%, the evaporative cooler loses efficiency. You’ll find open-loop evaporative cooling systems in dry regions, warehouses, and some factories. Evaporative coolers are simple, cost-effective, and use less energy than traditional conditioners. Just remember, in humid areas, an open-loop evaporative cooling system may not keep you comfortable.

| Humidity Level | Effect on Efficiency |

|---|---|

| Below 30% | Most effective |

| 30% – 50% | Reduced performance |

| Above 50% | Ineffective |

| Above 70% | Performance drops significantly |

Note: Evaporative coolers are great for dry climates but not for humid ones.

You have many types of cooling systems to choose from. Whether you need a central air conditioner, a mini-split, heat pumps, or an evaporative cooler, think about your space, climate, and comfort needs before picking a conditioner.

Enclosure Cooling Systems by Linkwell

When you work with sensitive electronics or industrial control panels, you know how important it is to keep everything cool and running smoothly. Linkwell offers a full lineup of enclosure cooling systems that help you protect your equipment, save energy, and avoid costly downtime. Let’s break down the main types you’ll find and see how each one fits different needs.

Heat Sink Coolers (HSC)

Heat sink coolers use air-to-air technology to move heat away from your enclosure. You get a simple, reliable way to manage temperature, especially in tight spaces. These systems work well in indoor manufacturing plants where space is at a premium. Linkwell’s heat sink coolers come packed with features that make your job easier and your equipment safer.

| Feature | Description |

|---|---|

| IP54 Design | Prevents water ingress, eliminating leaks. |

| Strong Centrifugal Fans | Distributes heat effectively, preventing hot spots. |

| Eco-Friendly Refrigerant | Utilizes R134a refrigerant, operational up to 60°C. |

| Compact Design | Thin and small, facilitating easy installation and maintenance. |

| Various Cooling Sizes | Available in sizes from 350W to 3500W, allowing for tailored cooling solutions. |

| Energy-Saving Thermostat Control | Regulates cooling operation to save energy and enhance equipment longevity. |

You’ll notice these coolers have a thin profile, so they don’t take up much space inside your cabinet. The corrosion-resistant fins last a long time, and you won’t have to worry about complicated maintenance. You can install them quickly, and the strong fans make sure heat gets pushed out evenly.

Heat Pipe Coolers (HPC)

Heat pipe coolers give you a smart way to handle heat in compact or outdoor enclosures. These systems use a small amount of fluid to move heat from hot spots to cooler areas. You get efficient energy transfer and minimal temperature differences, which is perfect when you need to cool specific components.

Heat pipe coolers stand out because they offer higher thermal conductivity than traditional aluminum plates. This means you get better performance at a lower cost compared to other conduction cooling methods. You’ll find these coolers excel at point-to-point thermal transfer, so they’re great for localized cooling needs. Vapor chambers, which are similar, help spread heat evenly across high-performance electronics.

- Heat pipes work best for moving heat from one spot to another.

- They keep temperature differences small, so your electronics stay safe.

- You can use them in places where space is tight or where you need to cool just one part of your system.

Vapor Compression Coolers (VCC)

Vapor compression coolers are the heavy hitters when you need serious cooling power. These systems use a compressor and refrigerant to pull heat out of your enclosure, making them ideal for medium to large cabinets. You’ll see vapor compression coolers in industries like telecom, automation, and data centers, where equipment generates a lot of heat.

| Advantage | Description |

|---|---|

| Efficiency | VCC systems are known for their high energy efficiency, making them the go-to choice for cooling large commercial and industrial spaces. |

| Compact Size | They are relatively compact and can be easily integrated into existing buildings. |

| Quick Cooling | VCCs offer rapid cooling, making them ideal for applications where fast temperature control is crucial. |

| Wide Application | They are versatile and can be used in various industries, from commercial buildings to data centers. |

You get a wide range of cooling capacities, so you can match the system to your needs. Compressor-based cabinet air conditioners from Linkwell can deliver up to 260W of cooling power, which means you can handle big heat loads without breaking a sweat. These systems are easy to install and maintain, and they keep your equipment running at peak performance.

Thermoelectric Coolers (TEC)

Thermoelectric coolers use solid-state technology to move heat, so you get quiet, reliable operation. These systems are perfect for small to medium enclosures, especially when you need to cool below the ambient temperature. You’ll love how precise they are—some can keep temperatures within half a degree Celsius.

| Benefit | Description |

|---|---|

| Reliability | Thermoelectric coolers have a high reliability with a lifespan exceeding 150,000 hours, making them suitable for remote locations with minimal monitoring. |

| Low Maintenance | With few moving parts and no need for filters or oils, thermoelectric systems are virtually maintenance-free compared to compressor-based systems that require regular upkeep. |

| Environmentally Friendly | These coolers do not use harmful chemical refrigerants, making them a more eco-friendly option compared to traditional air conditioning systems. |

| Precise Temperature Control | They can maintain target temperatures within ±0.5°C, offering better temperature stability than conventional systems that may have larger fluctuations. |

| Ability to Cool Below Ambient | Thermoelectric coolers can effectively cool below ambient temperatures, unlike heat pipes, which are limited by environmental conditions. |

| Heating Options | Some systems can switch between heating and cooling, providing year-round protection for sensitive electronics in varying climates. |

Thermoelectric coolers have no moving parts, so you get less noise and fewer things that can break. Their performance depends on the voltage and the temperature around them, but they’re a great choice when you want a low-maintenance, eco-friendly solution.

Applications and Benefits

You can use Linkwell’s enclosure cooling systems in all kinds of industries. Here’s a quick look at where each product shines:

| Cooling Product | Common Applications |

|---|---|

| Fan Filter Units | Factories, automation panels, CNC machines—great for dusty or industrial spaces |

| Cabinet Air Conditioners | Telecom, automation, power control—perfect for high-heat or outdoor environments |

| Electrical Cabinet Louvers | Control rooms, outdoor cabinets—ideal for passive airflow |

| Enclosure Thermostats | Control panels, automation, outdoor boxes—keeps temperatures in check |

When you choose the right system, you get big benefits:

| Benefit | Description |

|---|---|

| Improved Equipment Lifespan | Proper cooling prevents overheating and extends the life of your equipment. |

| Energy Efficiency | The right system ensures optimal energy use, reducing operational costs. |

| Enhanced Performance | Maintaining the correct temperature ensures your equipment operates at peak efficiency. |

| Reduced Downtime | Reliable cooling minimizes the risk of equipment failure and costly downtime. |

Linkwell’s cabinet air conditioners, electrical enclosure ventilation, and axial fans all work together to keep your systems safe and efficient. You can count on these solutions to protect your investment, lower your energy bills, and keep your operations running smoothly. If you’re not sure which enclosure cooling system fits your needs, Linkwell’s team can help you find the perfect match.

Industrial Cooling Systems and Technologies

When you step into a factory or a data center, you see how important industrial cooling systems are. These systems keep machines, electronics, and even entire buildings at safe temperatures. Let’s look at the main types you’ll find in modern industry.

Liquid Cooling Systems

You might notice that liquid cooling systems are everywhere in high-tech environments. These systems use liquids to pull heat away from equipment much faster than air. You get better energy efficiency and longer hardware life. Many data centers now use closed-loop dry cooling system designs, which recycle the same liquid and keep things clean and efficient.

Here’s what’s new in liquid cooling systems:

- Single-phase immersion cooling lets you submerge servers in special fluids. This keeps dust and vibration away.

- Two-phase immersion cooling uses boiling liquids for even more powerful cooling.

- Direct-to-chip liquid cooling systems send chilled liquid right to the hottest parts of your equipment.

You’ll see these industrial cooling systems in places with high-density servers or AI hardware. Closed-loop dry cooling system setups help you save energy and reduce noise. The market for these systems is growing fast, especially as more companies want sustainable solutions.

| Feature | Description |

|---|---|

| Cooling Method | Immersion cooling can be single-phase or two-phase, with two-phase offering superior heat transfer. |

| Heat Management Capability | Can handle rack densities exceeding 100kW with low PUE ratings. |

| Operational Advantages | Eliminates the need for air cooling, reduces component failure rates, and operates silently. |

| Environmental Benefits | Enables heat recovery at higher temperatures, suitable for district heating applications. |

Cooling Towers

A cooling tower is a classic part of many industrial cooling systems. It uses evaporation to remove heat from water cooling systems. You’ll find cooling towers in power plants, refineries, and factories. They work by sending warm water up to the top, where it meets air and cools down as some water evaporates.

But you should know about the environmental side. Cooling towers use a lot of water and energy. They need chemical treatments to keep the water clean, and they can release small droplets into the air. Closed-loop dry cooling system options can help reduce water use and lower chemical needs.

| Environmental Consideration | Description |

|---|---|

| Water Consumption | Cooling towers rely on evaporation, leading to significant water loss. |

| Energy Consumption | Mechanical draft cooling towers consume substantial electricity. |

| Water Quality and Chemical Use | Requires chemical treatment to prevent scaling and biofouling. |

| Air Quality and Drift Emissions | Cooling towers can release small droplets containing chemicals and pathogens. |

| Thermal Pollution | Heat discharge can alter local microclimates. |

| Noise Pollution | Fans and water noise can contribute to noise pollution. |

Specialized Solutions

Some industrial cooling systems need more than just water or air. You might use a closed-loop dry cooling system for high-heat processes, especially where water is limited. These systems use chilled air or fluids in a sealed loop, so you don’t lose water to evaporation.

Other options include:

- Air-cooled heat exchangers, which use fans to blow air over hot surfaces.

- Hybrid cooling systems, which mix air and water for better results.

- Closed-loop dry cooling system setups, which are easy to maintain and work well in remote areas.

Custom cooling system designs can double the lifespan of your equipment. You get lower temperatures and more reliable performance. Closed-loop dry cooling system technology is a smart choice if you want to save water and energy while keeping your operations safe.

Tip: Always match your industrial cooling systems to your process needs. The right closed-loop dry cooling system can make a big difference in cost and reliability.

Choosing the Right Cooling System

Key Factors to Consider

Picking the right cooling system can feel overwhelming, but you can make it easier by focusing on a few important points. Start by thinking about what your equipment needs and the space you have. Here are some key factors you should keep in mind:

- Material compatibility: Make sure the coolant and system parts work well together. Some materials can react and cause problems.

- Heat transfer requirements: Check if the system can handle the amount of heat your equipment produces. This helps keep everything running smoothly.

- System design constraints: Look at the size and shape of your space. Some cooling systems need more room than others.

- Heat absorption and dissipation: The system should absorb and release heat well to keep temperatures steady.

- Flow rate considerations: The coolant should move easily through the system for the best results.

- Longevity and maintenance needs: Choose a system that won’t need lots of repairs or downtime.

- Budgeting for coolants: Think about both the upfront cost and what you’ll spend over time.

You also want to look at energy efficiency. A system that uses less power saves you money and helps the environment. Don’t forget to consider how easy it is to maintain and if it fits your budget.

Matching Systems to Needs

Every space is different, so you want a cooling system that matches your exact needs. For small enclosures, you might need a compact solution. For large factories, you’ll want something powerful and reliable. Energy efficiency should always be a top priority, especially if you run equipment all day.

If you’re not sure what works best, talking to experts can help. Linkwell offers custom solutions that fit your project perfectly. Here’s how working with Linkwell can benefit you:

| Benefit | Description |

|---|---|

| Tailored Systems | Get a cooling system designed for your equipment and space, boosting operational efficiency. |

| Quick Turnaround | Fast production and delivery help you meet tight deadlines. |

| Comprehensive Support | You receive ongoing technical help and after-sales service to keep things running smoothly. |

Tip: Consulting Linkwell means you protect your electronics, extend equipment life, and improve safety. You also get more uptime and less stress.

Conclusion

You’ve just explored the main types of cooling systems and how each one fits different needs. Whether you want to keep your home comfortable, protect sensitive electronics, or manage heat in a busy factory, you have plenty of options. Picking the right cooling system can make a huge difference in how well your equipment works and how much you spend on repairs or energy.

Let’s recap what you’ve learned:

- Central air conditioners work best for cooling large spaces evenly.

- Mini-split systems give you flexibility and energy savings for smaller or unique spaces.

- Heat pumps offer both heating and cooling, making them a smart year-round choice.

- Evaporative coolers shine in dry climates where humidity stays low.

- Enclosure cooling systems from Linkwell protect your electronics and keep your operations running smoothly.

- Industrial cooling systems like liquid cooling and cooling towers handle heavy-duty jobs in factories and data centers.

Remember: The right cooling system helps you avoid downtime, save money, and extend the life of your equipment.

If you’re not sure which system fits your needs, don’t worry. Linkwell stands ready to help you with expert advice and custom solutions. You can trust their experience and wide range of products, from cabinet air conditioners to advanced enclosure ventilation and axial fans.

| Why Choose Linkwell? | What You Get |

|---|---|

| Decades of industry know-how | Reliable, tailored solutions |

| 24/7 support | Fast answers and ongoing assistance |

| Global reputation | Trusted by top brands worldwide |

Ready to take the next step? Reach out to Linkwell for a recommendation that matches your project. Investing in the right cooling system today means fewer headaches and better performance tomorrow. Stay cool and keep your equipment safe!

You’ve seen how cooling systems—from central air conditioners to enclosure solutions—keep your space and equipment safe. Picking the right system boosts reliability and saves you money over time. Linkwell stands out with expert support and custom solutions for industrial and enclosure cooling. If you want advice or a tailored recommendation, reach out to Linkwell. Investing in the right cooling system means less downtime, longer equipment life, and peace of mind.

Ready to upgrade your cooling? Contact Linkwell and get the perfect fit for your needs!

FAQ

What is the main benefit of using enclosure cooling systems?

You protect your electronics from overheating. This keeps your equipment running longer and helps you avoid costly repairs or downtime. You also get better performance and peace of mind.

How do I know which cooling system fits my needs?

Start by checking your equipment size, heat output, and environment. If you feel unsure, reach out to Linkwell. Their team can help you pick the best solution for your space.

Can I install Linkwell cooling products myself?

Most Linkwell products come with easy-to-follow instructions. You can handle basic installations if you have some experience. For complex setups, you might want a professional to help.

How often should I maintain my cooling system?

Check filters and fans every few months. Clean or replace parts as needed. Regular maintenance keeps your system efficient and extends its life.