You need to follow wiring standards required for terminal blocks like IEC 60947-7-1, UL 1059, and NEC 2026 to keep your electrical systems safe and reliable. In North America, UL 1059 is the standard, while Europe uses IEC 60947-7-1 and the Low Voltage Directive. Meeting these standards helps prevent electrical hazards; proper grounding alone can stop almost 30% of issues in facilities. High-quality terminal blocks boost system reliability. Linkwell stands out by offering products certified to UL, CE, and RoHS, helping you meet global requirements with confidence.

Key Takeaways

- Follow wiring standards like IEC 60947-7-1, UL 1059, and NEC 2026 to ensure safety and reliability in electrical systems.

- Choose certified products, such as Linkwell’s terminal blocks, to meet global safety requirements and avoid compliance issues.

- Always check the voltage and current ratings for your terminal blocks to prevent overheating and ensure stable connections.

- Implement proper grounding and circuit separation to enhance safety and reduce the risk of electrical hazards.

- Maintain clear documentation and labeling for your wiring projects to simplify troubleshooting and ensure compliance.

Wiring Standards Required for Terminal Blocks

Key International and US Standards

You need to know the wiring standards required for terminal blocks before you start any project. These standards make sure your spring terminal blocks work safely and reliably. They also help you avoid problems with insurance and legal requirements. Let’s look at the main standards you’ll see in 2026.

Here’s a quick table to help you compare the most important standards:

| Standard | Description |

|---|---|

| IEC 60947-7-1 | Applies to terminal blocks for copper conductors with rated voltage not exceeding 1,000 Vac or 1,500 Vdc. |

| UL 1059 | Specifies requirements for terminal blocks in the U.S. market. |

| NEC 2026 | Not specifically detailed in the retrieved results, indicating a gap in the information provided. |

IEC 60947-7-1 sets the rules for spring terminal blocks in Europe and many other regions. It covers voltage rating, current rating, and the types of connections you can use. UL 1059 is the standard for the U.S. market. It focuses on safety, flame resistance, and temperature tolerance. NEC 2026 will guide future trends in spring terminal block technology, but details are still emerging.

If you want to meet the wiring standards required for terminal blocks, you should always check the voltage rating and current rating for your application. Make sure your spring terminal blocks match the rated values. This keeps your connections safe and stable.

Tip: Always use spring terminal blocks that meet IEC and UL standards. This helps you avoid electrical hazards and keeps your installation legal.

Linkwell Product Compliance (Screw Terminal, Terminal Block Connector)

You want products that make compliance easy. Linkwell’s Screw Terminal and Terminal Block Connector give you peace of mind. Both products hold UL, CE, and IEC certifications. These certifications mean your spring terminal blocks meet the wiring standards required for terminal blocks in every major market.

Here’s a quick look at how these certifications help you:

- UL certification ensures your spring terminal blocks pass strict safety tests.

- CE marking guarantees your spring terminal blocks work across global markets.

- IEC compliance means your spring terminal blocks meet international wiring standards required for terminal blocks.

You also need to think about RoHS compliance. RoHS makes sure your terminal blocks are safe for the environment. This is important for legal and insurance reasons. The table below shows how each certification impacts your selection:

| Key Considerations | Impact on Terminal Block Selection |

|---|---|

| RoHS Compliance | Ensures environmental safety and compliance with regulations, crucial for legal and insurance requirements. |

| UL Certification | Guarantees testing for flame resistance and temperature tolerance, indicating reliability. |

| CE Marking | Confirms compliance with European safety and health regulations, ensuring suitability for applications. |

When you choose Linkwell’s Screw Terminal or Terminal Block Connector, you get products that meet all the wiring standards required for terminal blocks. You also get key features to consider when choosing terminal blocks, like modular design, easy installation, and strong connections. These products support both solid and stranded wires, so you can use them in many different applications.

Spring terminal blocks from Linkwell help you build safe, reliable connections. You can trust their certifications and quality. If you want to stay ahead of future trends in spring terminal block technology, Linkwell’s products are a smart choice.

Conductor Selection and Installation

Choosing the Right Conductor for Terminal Blocks

You want your spring terminal blocks to work safely and last a long time. Picking the right conductor is the first step. Start by checking the current rating and voltage rating for your application. If you use a wire that cannot handle the load, you risk overheating or even fire. Always match the wire gauge to the terminal blocks. This keeps your electrical connections stable.

Think about the environment. If you install spring terminal blocks in a place with high humidity or dust, choose wires with strong insulation. In places like the UAE, heat and moisture can cause corrosion or short circuits. You need to look at the ambient temperature range, exposure to chemicals, and vibration conditions. Indoor and outdoor use also matters. Here’s a quick table to help you decide:

| Criteria | Details |

|---|---|

| Maximum current per circuit | Check current rating for safety and efficiency. |

| Operating voltage | Make sure voltage rating fits your needs. |

| Wire gauge required | Use the right wire gauge for your terminal blocks. |

| Ambient temperature range | Pick insulation that handles the heat. |

| Exposure to moisture/dust | Choose insulation that resists corrosion. |

| Vibration conditions | Select wires that stay secure in spring terminal blocks. |

| Indoor vs. outdoor use | Use materials that match the installation environment. |

If you want to avoid common failures, make sure you insert wires fully and strip insulation correctly. Poor wire insertion leads to unstable connections. Corrosion can happen if you use the wrong materials or ignore moisture. Never force wires into terminal blocks. Always check compatibility.

Installation Best Practices with Linkwell Products

You want your spring terminal blocks to perform well for years. Linkwell’s Screw Terminal and Terminal Block Connector offer key features to consider when choosing terminal blocks. These products meet UL and CE standards, use flame-retardant housing, and support both solid and stranded wires. You get a double-layer design for space efficiency and a transparent panel for easy inspection.

Here are some practical tips for installing spring terminal blocks:

- Turn off the power before you start. Safety comes first.

- Strip wires to the right length, usually about half an inch. Don’t damage the strands.

- Insert wires fully into the terminal blocks. Tighten screws or use ferrules for secure connections.

- Inspect for loose connections, corrosion, or overheating. Replace worn parts quickly.

- Use tool-free rail mounting for fast and secure installation, especially in high-vibration areas.

- Clean terminal blocks regularly to prevent dust buildup and maintain reliable electrical connections.

Linkwell’s spring terminal blocks use flange face screws for a gas-tight connection. This reduces overheating risks. High-purity copper busbars boost conductivity. The insulated rail shield protects against accidental contact. These features help you meet international standards and keep your system safe.

If you want to stay ahead of future trends in spring terminal block technology, choose products that offer durability, easy installation, and strong connections. Linkwell’s solutions make your job easier and your electrical connections more reliable.

Grounding, Separation, and Safety

Grounding and Bonding for Terminal Blocks

You want your spring terminal blocks to keep your system safe and reliable. Proper grounding and bonding play a big role in this. If you follow UL 1059 and NEC 2026, you will meet the latest requirements for terminal blocks. Here’s a quick table to help you understand what you need to do:

| Requirement Type | Description |

|---|---|

| Grounding Methods | Equipment grounding conductors, grounding electrode conductors, and bonding jumpers must be connected using listed pressure connectors, terminal bars, or other listed means as per NEC NFPA70 Article 250.8. |

| UL Standards | UL 486A-B and UL 1059 are referenced for terminal blocks and grounding applications. |

If you skip proper grounding, you put your system at risk. Inadequate grounding and bonding can stop fault currents from flowing safely. This can leave metal parts at dangerous voltages. You could face electric shock or damage to your equipment. Without a low-impedance path, even parts that should not carry current can become energized. This is a serious safety hazard.

Tip: Always check that your spring terminal blocks use listed connectors and follow the latest standards. This step gives you improved safety and peace of mind.

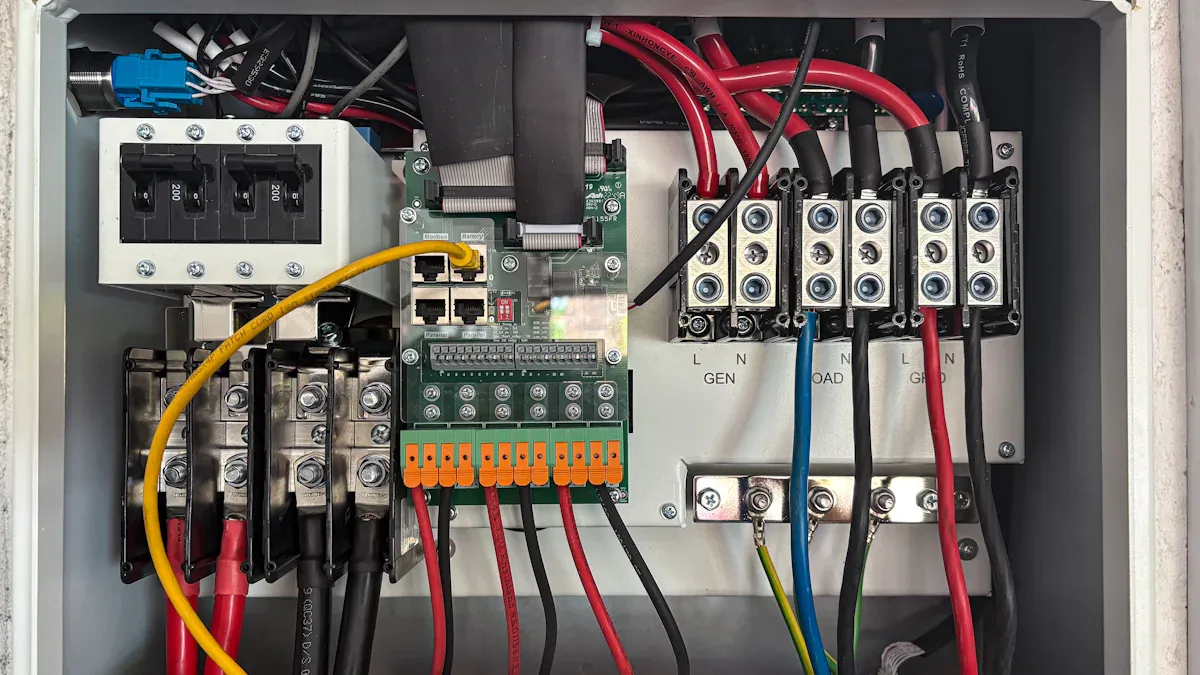

Circuit Separation and Field Wiring

You need to keep control and power circuits separate when you wire your spring terminal blocks. This helps prevent interference and keeps your connections clear. Good separation also makes troubleshooting easier and reduces the risk of accidental shorts.

Here are some key features to consider when choosing terminal blocks for separation and field wiring:

- Use color-coded spring terminal blocks to mark different circuits.

- Choose modular designs for flexible layouts.

- Pick products with clear labeling for fast identification.

Linkwell’s spring terminal blocks and terminal block connectors support these best practices. You get strong, secure connections and easy-to-read markings. The modular design lets you expand or change your setup as your needs grow. These features help you stay ready for future trends in spring terminal block technology.

If you want improved safety and reliable performance, always follow the latest standards for grounding, bonding, and circuit separation. Your system will thank you with fewer problems and longer life.

Cable Management, Documentation, and Testing

Cable Routing and EMC for Terminal Blocks

You want your wiring to look neat and work well. Good cable management is more than just making things tidy. It helps you avoid problems with your spring terminal blocks and keeps your system running smoothly. When you route cables to terminal blocks in industrial panels, you should follow clear guidelines. The National Electrical Code says you need to keep enough space between wires. This stops design mistakes that can cause trouble later. Try to keep wire lengths reasonable. Long wires can tangle and add resistance, which hurts performance.

Plan your wiring early. Draw a detailed diagram before you start. This helps you see where each wire goes and keeps sensitive wires away from power cables or hot parts. If you use Linkwell’s modular spring terminal blocks, you get flexible layouts and easy cable routing. The modular design lets you add or move blocks as your needs change. You also get better electromagnetic compatibility (EMC) because you can separate signal and power wires.

Tip: Neat cable routing not only looks good but also makes future maintenance much easier.

Labeling, Documentation, and Verification

Clear labeling and good records are key for any project with spring terminal blocks. In 2026, you must follow UL 508A standards. This means you need to document things like conductor size, how you connect wires, and your testing steps. Every wire should have a number or label that matches your wiring diagram. This makes it easy to trace wires from the field to the panel.

Modern panels often use QR codes or machine-readable labels. These give you fast access to circuit details. Linkwell’s terminal blocks support easy labeling, so you can mark each connection clearly. This helps you find problems quickly and keeps your system safe.

Testing is the last step. You should check:

- Clearance and creepage distances between conductive parts

- SCCR rating for short-circuit safety

- Derating curve for current capacity

- Temperature rise under load

- Impulse withstand voltage

- Short-time withstand current

- Dielectric strength of insulation

When you follow these steps, you make sure your spring terminal blocks and terminal blocks meet all standards. You get reliable connections and peace of mind about safety.

Conclusion

You’ve learned about the wiring standards required for terminal blocks in 2026. These rules help you keep your electrical systems safe and reliable. When you follow standards like IEC 60947-7-1, UL 1059, and NEC 2026, you protect your equipment and everyone who uses it.

Choosing certified products makes your job easier. Linkwell’s Screw Terminal and Terminal Block Connector give you peace of mind. You get UL, CE, and RoHS certifications, so you know your connections meet global safety rules. These products also support strong cable management and clear labeling, which helps you avoid mistakes.

Remember, checking the current and voltage rating for each terminal block is key. This step keeps your system running smoothly and prevents overheating.

Here’s what you can do next:

- Review your wiring plans and make sure you use certified terminal blocks.

- Check your installation for proper grounding and circuit separation.

- Keep your documentation up to date for every project.

- Test your connections before you power up your system.

If you want to stay ahead, keep learning about new standards and best practices. You can reach out to Linkwell or talk to industry experts for advice on your next project. Regular compliance checks help you avoid problems and keep your systems running safely.

You’re ready to build safer, smarter electrical panels. Good luck with your next installation!

You need to follow wiring standards like UL, IEC, and NEC for terminal blocks in 2026. Picking certified products such as Linkwell’s Screw Terminal and Terminal Block Connector helps you avoid safety risks and meet fire resistance, shock-proof, and arc suppression requirements.

| Maintenance Task | Recommended Interval |

|---|---|

| Visual inspection for overheating/moisture | Quarterly |

| Full internal cleaning | Yearly |

| Infrared thermography scan | Annually |

Stay sharp by checking your system often and keeping up with new rules. If you face tricky wiring problems, reach out to Linkwell or talk to industry experts for advice.

FAQ

What wiring standards should you follow for terminal blocks in 2026?

You should use IEC 60947-7-1, UL 1059, and NEC 2026. These standards keep your electrical panels safe and legal. Always check your local regulations before starting any project.

How do you choose the right Linkwell terminal block for your project?

Pick a terminal block based on wire size, current rating, and installation environment. Linkwell’s Screw Terminal and Terminal Block Connector work with both solid and stranded wires. You can find more details on the Linkwell website.

Do Linkwell terminal blocks meet international safety standards?

Yes! Linkwell terminal blocks carry UL, CE, and RoHS certifications. You get reliable products that meet global safety requirements. These certifications help you pass inspections and avoid compliance issues.

How often should you inspect and maintain your terminal blocks?

| Task | Interval |

|---|---|

| Visual inspection | Quarterly |

| Full cleaning | Yearly |

| Infrared scan | Annually |

Regular checks help you catch problems early and keep your system running smoothly.

Can you get help with installation or troubleshooting from Linkwell?

Absolutely! You can contact Linkwell’s support team 24/7 for advice, troubleshooting, or custom solutions. Just reach out by phone, email, or WeChat for fast help.