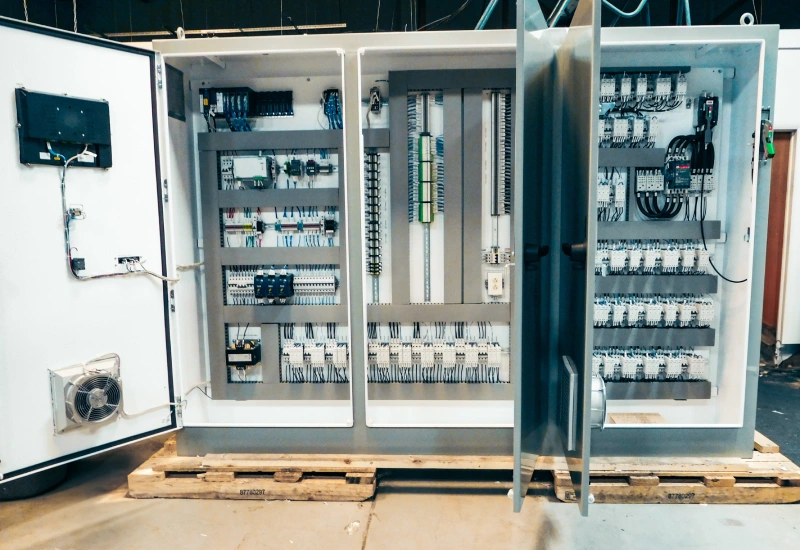

When you look inside an industrial control panel, you’ll find a few essential components that keep everything running safely and smoothly. Here’s what you’ll usually see:

| Component | Function |

|---|---|

| Circuit Breakers | Protects electrical circuits from overload or short circuits by automatically disconnecting the power supply. |

| Fuses | Provides overcurrent protection by breaking the circuit when excessive current flows through. |

| Relays | Electrically operated switches used to control the flow of electricity in a circuit, often used for automation. |

| Contactors | Heavy-duty electrical switches used to control electric motors and other high-power applications. |

| Transformers | Changes voltage levels to either step up or step down the electrical power for specific use cases. |

| Power Supplies | Provides the necessary electrical power to run control panel components and equipment. |

| Programmable Logic Controllers (PLCs) | Controls automated industrial processes by receiving input from sensors and executing programmed commands. |

| Motor Drives | Controls the speed, torque, and operation of electric motors to optimize industrial machinery performance. |

| Terminal Blocks | Provides a convenient and secure way to connect electrical wires in control panels. |

| Switches | Manual or automatic devices used to open or close an electrical circuit for control purposes. |

| Indicators | Provide visual signals (like LED lights) to indicate the operational status of equipment or circuits. |

| Ethernet Switches | Facilitates communication between industrial control systems, enabling data transfer over local area networks. |

| Sensors | Detects changes in the environment (temperature, pressure, motion) and sends signals to the control system for processing. |

| Cooling System | Maintains an optimal temperature within the control panel to prevent overheating of electrical components. |

| Cable Management | Organizes and secures wires and cables to ensure proper airflow and prevent damage or tangling. |

Each of these industrial control panel components plays a crucial role. Circuit breakers and fuses protect against overloads, while relays and contactors handle heavy electrical loads. PLCs and sensors take care of automation. By choosing the right control panel components, you make sure your system stays reliable and efficient. Linkewell’s experience helps you select the most essential components for every application.

Recommended products

Key Takeaways

- Industrial control panels use key parts like circuit breakers, PLCs, sensors, and power supplies to keep machines safe and running smoothly.

- Choosing the right enclosure and components protects your system from damage and helps it work efficiently in different environments.

- Automation devices like PLCs and relays make your operations smarter and reduce errors by controlling machines automatically.

- Safety features such as emergency stops, overload protection, and clear labeling keep your team safe and prevent costly downtime.

- Working with experts like Linkewell ensures you get quality parts, custom solutions, and support to build reliable, future-ready control panels.

What is an Industrial Control Panel

Definition & Purpose

When you hear the term industrial control panel, you might picture a metal box filled with wires and switches. In reality, it’s much more than that. An industrial control panel is an assembly of electrical components—like relays, circuit breakers, and controllers—designed to manage and automate machines or processes in factories and other industrial settings. These panels operate at 1000 volts or less and usually come in two types: enclosed (with all parts inside a protective case) or open (where parts need to be installed in a safe enclosure at the site).

Here’s what makes industrial control panels so important:

- They distribute power to machines and equipment, making sure everything gets the right amount of electricity.

- They automate tasks using devices like PLCs and relays, which helps you boost productivity and reduce mistakes.

- They monitor things like voltage, temperature, and current, so you can spot problems before they cause downtime.

- They keep you and your team safe by including emergency stops, disconnect switches, and overload protection.

- They provide a user-friendly interface, like an HMI, so you can control and adjust settings easily.

- They protect sensitive components from dust, moisture, and accidental contact.

Take a look at this quick overview of what industrial control panels do:

| Function | Description |

|---|---|

| Power Distribution | Routes electricity to machines and keeps systems stable |

| Automation Control | Uses PLCs and relays to automate operations |

| System Monitoring | Tracks voltage, current, and temperature for early fault detection |

| Safety Management | Includes emergency stops and overload protection |

| Operator Interface | Lets you monitor and adjust settings in real time |

Linkewell’s Role

You want your industrial control panel to be reliable, safe, and ready for the future. That’s where Linkewell comes in. Linkewell stands out as a trusted partner in the global market, offering a wide range of high-quality products for industrial control panels. The company focuses on quality, competitive pricing, and fast delivery, making it a top choice for businesses that need dependable solutions.

Linkewell doesn’t just supply parts. You get expert support for design, assembly, and even custom solutions. Their team helps you choose the right components, ensures your panel meets safety standards, and provides after-sales service. With Linkewell, you can feel confident that your industrial control panels will keep your operations running smoothly, no matter how complex your needs are.

Primary Components of a Control Panel

When you open an industrial control panel, you see a well-organized system. Each part has a job to do. Let’s walk through the main control panel components you’ll find inside.

Enclosure & Backplate

The enclosure is the shell that keeps everything safe. It protects the internal parts from dust, water, and accidental contact. You can choose from different materials like steel, stainless steel, or non-metallic types. The right choice depends on where you plan to use the panel. For example, stainless steel works well in harsh or wet environments.

Here’s a quick look at common enclosure materials and their uses:

| Material Type | Description/Use Case |

|---|---|

| Aluminum | Lightweight, corrosion resistant, commonly used |

| Carbon Steel | Strong, cost-effective, often powder-coated |

| Stainless Steel | Corrosion resistant, great for harsh environments |

| Powder-Coated Steel | Extra durable, long-lasting protection |

You also need to think about protection ratings. NEMA ratings tell you how much protection the enclosure gives. For example, NEMA 1 and 12 are for indoor use, while NEMA 4 and 4X are for outdoor or wet areas. NEMA 7 is explosion-proof for hazardous places.

| NEMA Protection Rating | Protection Characteristics |

|---|---|

| NEMA 1 | Indoor, dust and light splashes |

| NEMA 12 | Indoor, dust, dirt, dripping water |

| NEMA 4 | Indoor/outdoor, windblown dust, rain, hose water |

| NEMA 4X | Like NEMA 4, plus corrosion resistance |

| NEMA 7 | Explosion-proof, hazardous locations |

The backplate, or sub-panel, sits inside the enclosure. It holds all the industrial control panel components in place. You want a sturdy backplate so your wiring and devices stay secure.

Tip: Linkewell offers enclosures and backplates in many sizes and materials, with options for custom layouts and high IP/NEMA ratings.

Power Supply & Transformers

The power supply is the heart of your panel. It takes incoming AC power and converts it to the DC voltage your devices need. Most control panel components run on 24 Vdc, which is safe and reliable. You might see input voltages like 120 Vac or 230 Vac, depending on your location.

| Power Supply Aspect | Details |

|---|---|

| Input Voltage | 120 Vac or 230 Vac |

| Output Voltage | 24 Vdc (for PLCs and automation devices) |

| Current Ratings | 3 A, 4 A, 12 A, 16 A |

| Voltage Conversion Steps | Step down from 480 Vac or 230 Vac to 120 Vac, then to 24 Vdc |

| Additional Devices | Isolation transformers, constant voltage transformers |

Transformers step down high voltages to safer levels. They also help protect sensitive equipment from surges and voltage swings. Linkewell’s power supply solutions are built for reliability and meet global standards.

Circuit Breakers & Fuses

Circuit breakers and fuses protect your panel from overloads and short circuits. If something goes wrong, they cut off the power fast. This keeps your equipment and team safe.

- Circuit breakers can be reset after tripping.

- Fuses need to be replaced if they blow.

You’ll find different types and ratings. For example, Class L fuses handle up to 6000 A, while Class CC fuses are for smaller circuits up to 30 A. The right choice depends on your load and safety needs.

Note: Always match the current rating to your circuit. This helps prevent nuisance trips and keeps your system running smoothly.

Disconnect Switches

Disconnect switches let you safely turn off power for maintenance or emergencies. You usually find them mounted outside the panel. This way, you can shut down a circuit without opening the enclosure.

- These switches must meet standards like UL 508A, NFPA 79, and NEC.

- NEC says you need a local disconnect switch in sight of the motor.

- Door interlocks make sure you can’t open the panel while it’s live.

You want clear markings and easy access for safety.

Terminal Blocks

Terminal blocks organize your wiring. They give you safe, secure connections for all your wires. You don’t need to solder anything—just clamp the wire in place.

| Terminal Block Type | Key Function and Contribution to System Reliability |

|---|---|

| Feed-thru Terminal Blocks | Connect two wires securely; easy inspection or repair. |

| Ground Terminal Blocks | Provide grounding, boosting safety. |

| Fused Connection Terminal Blocks | Add fuses and LEDs for overcurrent protection and fault indication. |

| Multi-Level Terminal Blocks | Save space, support complex wiring for sensors and actuators. |

| Disconnect Terminal Blocks | Allow quick disconnection for maintenance. |

| Power Distribution Blocks | Split power from one source to many outputs. |

A good terminal block setup makes troubleshooting and upgrades much easier. Linkewell’s terminal blocks are known for their durability and clear labeling.

Relays & Contactors

Relays and contactors act as switches. Relays handle low to medium currents and are perfect for automation and safety circuits. Contactors control high-power devices like motors and heavy machinery.

- Use relays for control signals, alarms, and small loads.

- Use contactors for starting and stopping motors, HVAC, and lighting.

You can’t swap these devices. Pick the right one for your application to keep your industrial control panel components working safely.

Programmable Logic Controllers (PLCs)

PLCs are the brains of your control panel. They automate tasks, process inputs from sensors, and send commands to other devices. You’ll see PLCs in almost every modern industrial control panel.

| Brand | Leading Models / Series | Key Features and Industry Focus |

|---|---|---|

| Siemens | SIMATIC S7-1200, S7-1500 | Robust, versatile, global support, AI and IoT integration |

| Allen-Bradley | ControlLogix, CompactLogix | Strong in manufacturing, oil & gas, automotive |

| Mitsubishi Electric | MELSEC PLC series | High performance, integrates with industrial robots |

| Schneider Electric | Modicon PLCs | Energy management, EcoStruxure platform |

| Omron | CJ and CS series | High-speed, advanced sensor integration |

You can program PLCs to handle everything from simple on/off control to complex automation. Linkewell’s panels support all major PLC brands, so you get flexibility for your project.

Human-Machine Interface (HMI)

The human-machine interface is your window into the system. HMIs let you monitor and control machines with a touchscreen or display. You can see real-time data, alarms, and system status at a glance.

- HMIs reduce downtime by giving you quick access to controls.

- Modern HMIs offer multi-touch screens, graphical data, and remote monitoring.

- You can connect HMIs to PLCs and other devices using Ethernet or USB.

Note: A good human-machine interface makes your job easier and helps you spot problems before they grow.

Motor Drives & Starters

Motor drives and starters control how motors start, stop, and run. Starters protect motors from overloads and let you automate motor control. Drives, like variable frequency drives (VFDs), adjust motor speed to save energy and extend equipment life.

| Type of Motor Drive/Starter | Main Functions and Characteristics |

|---|---|

| Starter Panel | Basic motor control, includes overload protection. |

| Motor Control Center | Centralizes power and control for multiple motors. |

| Across-The-Line Combination Starters | Start three-phase motors, include overload relay and push button control. |

| Explosion Proof Starters | Safe for hazardous environments. |

| Multi-Speed and Reduced Voltage Starters | Control speed and reduce stress on motors. |

| Multi-Motor Starter Panels | Start several motors at once, include disconnects and controllers. |

| Duplex Pump Panels | Control two pumps, often with alarms and remote control. |

You’ll find motor drives in HVAC, conveyors, and pumps. Linkewell’s motor control panels use certified components for safe, efficient operation.

Surge Suppressors & Overload Relays

Surge suppressors protect your panel from voltage spikes. Overload relays keep motors safe by shutting them down if they draw too much current. Both devices must meet standards like UL, CE, and IEC.

- Surge suppressors guard against lightning and power surges.

- Overload relays prevent overheating and motor damage.

You want these control panel components to meet strict safety standards for peace of mind.

Communication Devices

Communication devices connect your panel to the outside world. They let your PLCs, HMIs, and sensors talk to each other and to remote systems.

- Common protocols include Modbus, EtherCAT, OPC UA, PROFIBUS, CANopen, DeviceNet, Ethernet/IP, and PROFINET.

- These devices support real-time data exchange, remote monitoring, and smart automation.

You can use Ethernet switches, industrial radios, or fieldbus modules. Linkewell’s panels support all major communication devices for seamless integration.

Wire Ducts & DIN Rails

Wire ducts and DIN rails keep your panel neat and organized. Wire ducts hold and route cables, making installation and maintenance easier. DIN rails provide a standard way to mount devices like terminal blocks, relays, and circuit breakers.

| Component | Standard Dimensions (mm) | Length (m) | Material | Additional Details |

|---|---|---|---|---|

| DIN Rails | 35 x 7.5, 15 x 7.5 | 1 or 2 | Aluminum or cold rolled steel | Conforms to DIN EN 60715; slotted or non-slotted; easy mounting |

| Wiring Duct | Various slot sizes | 2 | UL94V0 flame retardant PVC | Available in gray and white; removable fingers; includes cover and accessories |

Sensors & Indicators

Sensors and indicators give you feedback about your system. Sensors measure things like temperature, pressure, position, and flow. Indicators show you system status with lights or displays.

| Sensor Type | Function/What It Does | Common Uses/Applications |

|---|---|---|

| Position Sensors | Detect orientation or distance of objects | Robotics, automotive systems |

| Pressure & Force | Measure mechanical or fluid pressure | Industrial machines, HVAC, braking systems, scales |

| Temperature & Humidity | Monitor heat and moisture levels | Climate control, manufacturing, agriculture, electronics |

| Vibration Sensors | Detect oscillations in machinery | Predictive maintenance, fault diagnosis |

| Motion Sensors | Detect movement or presence | Security, automatic lighting, safety shutdowns |

| Flow Sensors | Measure rate or quantity of fluid/gas flow | Water treatment, chemical processing, fuel systems |

| Level Sensors | Monitor material levels in containers | Inventory management, safety systems, process control |

You’ll use sensors and input devices to monitor everything from machine speed to room temperature. Indicators help you spot problems fast.

Electrical Power Distribution Box by Linkewell

The electrical power distribution box is a key part of many industrial control panel components. It splits incoming power into multiple circuits and protects each one from overloads. Linkewell’s distribution boxes are built to IEC 61439 and UL 508A standards. You can choose from steel, stainless steel, or polycarbonate enclosures, all with high IP ratings for dust and water protection.

- Pre-cut cable entries and labeled terminals make installation quick.

- Custom sizes and layouts fit your exact needs.

- These boxes work well in factories, telecom, and data centers.

Note: Linkewell’s distribution boxes help you save time and boost safety, making them a smart choice for any industrial control panel.

Component Integration & Operation

When you look at an industrial control panel, you see more than just a collection of parts. Each component works together to deliver power, automate processes, and keep your team safe. Let’s break down how this happens inside a modern electrical control panel.

Power Distribution

Power distribution is the backbone of every electrical control panel. The process starts with the power supply, which converts high-voltage AC into low-voltage DC for your sensitive devices. Transformers adjust voltage levels so each part gets exactly what it needs. Power distribution blocks split the main power into smaller circuits, making sure every device receives safe and steady electricity.

Here’s a quick look at how these components interact:

| Component | Function and Interaction |

|---|---|

| Power Supply | Converts AC to DC, regulates voltage for stable operation. |

| Transformer | Steps voltage up or down to match device requirements. |

| Power Distribution Block | Routes power to different circuits for safe, efficient use. |

| Terminal Block | Connects and organizes wiring, ensuring reliable connections. |

| Relays & Contactors | Control power flow to motors and devices based on commands from the PLC. |

| Circuit Breakers & Fuses | Protect against overloads and short circuits, keeping the system safe. |

In Linkewell’s electrical control panels, you get all these features in a neat, organized layout. This setup helps you avoid downtime and keeps your equipment running smoothly.

Control & Automation

Automation control is what makes your industrial control panel smart. You use push buttons and switches to send signals. Relays act as messengers, turning those signals into action. The programmable logic controller (PLC) is the brain, running automated sequences and making decisions based on input from sensors.

You can see how these parts work together in this table:

| Component | Automation Function |

|---|---|

| Push Button | Starts or stops machines with a simple press. |

| Relay | Switches devices on or off based on control signals. |

| PLC | Runs complex logic, automates tasks, and processes sensor data. |

| HMI | Lets you monitor and adjust settings in real time. |

| VFD | Controls motor speed for energy savings and smooth operation. |

| Sensors | Feed real-time data to the PLC for smarter automation. |

With Linkewell’s electrical control panel, you can easily add or upgrade automation features. The modular design supports everything from basic motor control to advanced system monitoring.

Safety & Monitoring

Safety and monitoring are at the heart of every electrical control panel. You rely on safety devices like emergency stop buttons and interlock switches to protect your team. Sensors keep an eye on temperature, pressure, and other key factors, sending alerts if something goes wrong.

For best results, follow these tips:

- Place safety devices where operators can reach them fast.

- Use sensors to track heat, humidity, and machine status.

- Add indicators and alarms for instant feedback.

- Keep enough space inside the panel for airflow and future upgrades.

- Label wires and devices clearly for quick troubleshooting.

Linkewell’s electrical control panels include built-in monitoring and safety features that meet strict standards. You get peace of mind knowing your system is protected and easy to maintain.

Remember: Good system monitoring and safety practices help you spot problems early and keep your operations running without interruption.

Quality, Compliance & Best Practices

Standards & Certifications

When you build or upgrade an electrical control panel, you want to make sure it meets the right standards. These standards keep your team safe and help your equipment last longer. The most recognized certifications for control panel components are UL 508A and IEC 61439. Here’s a quick comparison:

| Aspect | UL 508A | IEC 61439 |

|---|---|---|

| Region | U.S. & Canada | International (Europe, Asia, etc.) |

| Focus | Industrial Control Panels | Low-voltage switchgear & controlgear assemblies |

| Certification | Required for North American markets | Used globally, mandatory in some regions |

| Testing | Panel-level testing | System-level testing |

You might also see NEC, NFPA 79, and CE marking. These rules make sure your control panel specifications match local and global safety needs. Certified panels protect against electrical hazards and help you avoid costly downtime.

Design & Layout

Great panel design is about more than just fitting everything inside a box. You want your control panel components to be easy to reach, well-organized, and safe to use. Here are some best practices for panel design:

- Group related parts together for better airflow and easier troubleshooting.

- Use clear labels and color-coded wires to avoid confusion.

- Keep high-voltage and low-voltage areas separate for extra safety.

- Plan for future upgrades by leaving space and adding diagnostic ports.

- Install safety devices like circuit breakers, emergency stops, and lockout-tagout systems.

- Use wire ducts and DIN rails to keep cables neat and prevent overheating.

- Make sure there’s enough room for ventilation and cooling fans.

Tip: Good panel design helps you spot problems fast and keeps your team safe during maintenance.

Linkewell’s Quality Commitment

You want a partner who cares about safety and reliability as much as you do. Linkewell puts quality first in every step of making control panel components. They use certified parts, invest in research, and test every product before it leaves the factory. Their team supports you with expert advice on panel design, wiring, and installation. You get detailed documentation and clear labeling, which makes maintenance and upgrades simple. Linkewell’s focus on innovation means your panels stay up to date with the latest safety and control panel specifications. When you choose Linkewell, you know your electrical control panel will meet strict standards and deliver long-lasting performance.

You’ve seen how each industrial control panel component plays a unique part in keeping your systems running smoothly. When you select the right parts, you boost efficiency, simplify maintenance, and improve safety.

- Always match your panel to your power needs and plan for future upgrades.

- Choose quality components and work with experts who know the standards.

If you want custom solutions or need help picking the best products, reach out to Linkewell’s team for support and guidance.

FAQ

What’s the most important component in an industrial control panel?

Every part matters, but the power supply is key. Without it, nothing works. Circuit breakers and PLCs also play big roles. You need all these to keep your system safe and running.

How do I choose the right enclosure for my control panel?

Think about where you’ll install the panel. For dusty or wet places, pick an enclosure with a high NEMA or IP rating. Stainless steel works well in harsh environments. Always match the enclosure to your site’s needs.

Can I upgrade my control panel later?

Yes! Most panels use modular designs. You can add new relays, PLCs, or sensors as your needs change. Just make sure you leave enough space inside for future upgrades.

How often should I inspect my control panel components?

Check your panel every six months. Look for loose wires, dust, or signs of wear. Regular inspections help you catch problems early and avoid downtime.

Does Linkewell offer custom solutions for unique projects?

Absolutely! Linkewell specializes in custom layouts, sizes, and features. You can get expert advice and support for any project, big or small. Just reach out to their team for help.