When you look at cooling electrical enclosures, you need to know the four primary heat transfer mechanisms: conduction, convection, radiation, and phase change cooling. Conduction moves heat through direct contact between surfaces inside enclosures. Convection uses air movement to carry heat away, whether it’s natural or forced airflow. Radiation lets heat escape as energy waves from hot surfaces.

Phase change cooling absorbs heat by changing materials from solid to liquid or liquid to gas. Each of these heat transfer mechanisms for electrical enclosures plays a big role in keeping temperatures safe. Industry studies show that managing heat with these types of heat transfer methods can double the lifespan of your electrical components. When you control heat buildup, you avoid early failures and keep your systems running strong.

Cooling Electrical Enclosures Key Takeaways

- Four main heat transfer types—conduction, convection, radiation, and phase change—work together to cool electrical enclosures effectively.

- Choosing materials with high thermal conductivity and using thermal interface materials improve heat conduction inside enclosures.

- Forced convection with fans and fan filter units boosts airflow and removes heat faster than natural airflow alone.

- Phase change materials absorb heat during melting to keep enclosure temperatures stable without extra energy use.

- Selecting the right cooling method depends on heat load, environment, and safety standards to protect equipment and ensure reliability.

Heat Transfer Mechanisms Overview

Understanding the heat transfer mechanisms for electrical enclosures helps you keep your equipment safe and reliable. Let’s break down the four main types of heat transfer and see how you can use them for cooling electrical enclosures.

Conduction in Electrical Enclosures

Conduction moves heat through solid materials inside your enclosure. When you touch a metal surface, you feel heat transfer because molecules bump into each other and pass energy along. In electrical enclosures, conduction happens when heat travels from hot components to the enclosure walls or heatsinks.

Here’s a quick look at the most common enclosure materials and their thermal conductivities:

| Material | Thermal Conductivity (W/m·K) |

|---|---|

| Aluminum | ~235 |

| Carbon Steel | ~45 |

| Stainless Steel | ~15 |

Aluminum works best for conduction because it moves heat quickly. If you use carbon steel or stainless steel, heat transfer slows down. You can boost conduction by making sure surfaces are flat and using thermal interface materials like paste or pads. These fill gaps and help heat flow better. When you design your enclosure, pick materials with high thermal conductivity and keep the contact area large but the path thin. This makes conduction more efficient.

Tip: Always check that your enclosure baseplate sits flat against heatsinks or other cooling surfaces. Use pressure and thermal paste to reduce air gaps.

Linkwell’s cabinet air conditioners and fan filter units use conduction to move heat from inside components to the enclosure walls and then out to the environment. Good conduction means less risk of overheating and longer life for your electronics.

Convection and Cooling

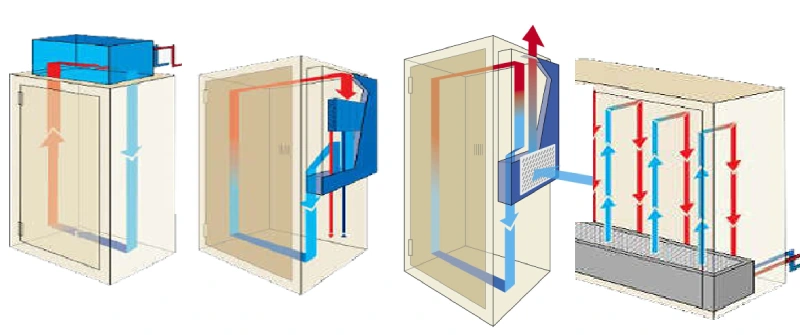

Convection is all about heat removal by fluid movement. In electrical enclosures, convection uses air to carry heat away from hot surfaces. You get two types: natural convection and forced convection. Natural convection happens when warm air rises and cool air sinks, creating a gentle flow. Forced convection uses fans or blowers to push air faster, which cools things down more quickly.

You can calculate airflow rates for effective convection cooling like this:

- Airflow (CFM) = BTU/hr ÷ (1.95 × ∆T°C)

- Add a safety margin of 25% to your calculated airflow.

- Use fans with at least three times the calculated airflow to overcome resistance.

Fan filter units from Linkwell boost forced convection. They pull in clean air, filter out dust, and keep a steady flow inside your enclosure. This keeps your electronics cool and safe. If your heat load is high, you might need cabinet air conditioners or air-to-air heat exchangers. Proper placement of components and vents helps airflow and makes cooling more effective.

Note: Forced convection works best when you combine it with good enclosure design and regular filter maintenance.

Convection is the main way you remove heat from heatsinks and enclosure walls. It’s a key part of effective thermal management for electrical systems.

Radiation Mechanism

Radiation transfers heat as energy waves from hot surfaces to cooler surroundings. You don’t need direct contact or air movement for radiation to work. In electrical enclosures, radiation helps release heat from the outside surfaces, especially if you use special coatings.

Surface finishes matter a lot. High-emissivity coatings, like white or black paint, help your enclosure radiate heat better. White coatings reflect sunlight and radiate heat efficiently, keeping internal temperatures lower. Black coatings absorb more heat but still radiate well. Plain aluminum doesn’t radiate much heat, so it’s less effective.

Did you know? Anodized surfaces can boost emissivity from 0.04 to 0.86, making radiation much more efficient.

Radiation becomes more important at higher temperatures or in outdoor applications. Linkwell’s enclosures can use high-emissivity coatings to improve radiation cooling, especially for photovoltaic panels or outdoor electrical boxes.

Phase Change Cooling

Phase change cooling uses materials that absorb heat when they melt or evaporate. These phase change materials (PCMs) keep your enclosure temperature steady by soaking up heat during peak periods and releasing it when things cool down.

Here’s a table of common PCMs and their properties:

| PCM Type | Usage in Electrical Cooling | Melting Temp (°C) | Latent Heat | Thermal Conductivity | Advantages | Disadvantages |

|---|---|---|---|---|---|---|

| Paraffin Waxes | Widely used | 50 – 90 | Low | Low | Stable, cheap, safe | Lower heat storage, slow flow |

| Salt Hydrates | Popular (e.g., Glauber’s) | 50 – 90 | High | Higher | More heat storage | May degrade, needs encapsulation |

| Non-Paraffin Organics | Special needs | 0 – 120 | Moderate | Moderate | Wide temp range, safer | More expensive |

| Metal PCMs | Limited use | Varies | Excellent | Excellent | Best thermal properties | Heavy, costly |

PCMs work passively, so you don’t need extra energy. They absorb heat during the day and release it at night, which saves energy and lowers costs. You can combine PCMs with other cooling methods for even better results. Linkwell’s solutions can integrate PCMs for passive cooling in sensitive or remote applications.

Block Quote: Passive cooling with PCMs can cut energy use by up to 90% and keep your enclosure temperature stable, even during hot spells.

When you use phase change cooling, you get efficient thermal management without extra power. It’s a smart choice for energy savings and reliability.

Summary Table: Heat Transfer Mechanisms for Electrical Enclosures

| Mechanism | How It Works | Where It’s Used | Linkwell Solution Example |

|---|---|---|---|

| Conduction | Heat moves through solids | Enclosure walls, heatsinks | Cabinet AC units, enclosure design |

| Convection | Heat carried by air movement | Inside enclosures, heatsinks | Fan filter units, air conditioners |

| Radiation | Heat radiates from surfaces | Outdoor enclosures, PV panels | High-emissivity coatings, design |

| Phase Change | Heat absorbed during melting | Passive cooling applications | PCM integration, hybrid solutions |

When you understand these types of heat transfer, you can choose the best cooling method for your electrical enclosures. Linkwell’s products use all four mechanisms to deliver effective thermal management and keep your systems running smoothly.

Practical Cooling Methods

Passive Cooling Solutions

You can start with passive cooling when you want a simple way to manage heat in electrical enclosures. Passive cooling uses natural heat dissipation through conduction, convection, and radiation. You don’t need power or moving parts, so it’s silent and reliable. If you use aluminum enclosures and place them in shaded areas, you boost heat transfer. However, passive cooling works best when the ambient temperature stays below your target. In hot climates, passive cooling struggles to keep up, especially when temperatures rise above 95°F. At that point, you need more than airflow alone to protect sensitive electrical components.

Here’s a quick comparison of passive and active cooling:

| Feature | Passive Cooling | Active Cooling |

|---|---|---|

| Energy Use | No power consumption during operation | Requires electricity to run fans, pumps, etc. |

| Noise & Vibration | Silent, no moving parts | Produces audible noise and possible vibration |

| Temperature Control | Limited to ambient conditions | Precise control, can cool below ambient temp |

| Complexity & Maintenance | Simple design, low maintenance | More components, higher maintenance needs |

| Cost (initial & operating) | Lower upfront and operating costs | Higher capital and operating expenses |

| Reliability | High reliability, no moving parts | Dependent on lifespan of mechanical parts |

Tip: Passive cooling is great for low heat loads and mild climates, but you should consider active solutions for high-performance or outdoor applications.

Forced Ventilation and Fan Filter Units (electrical enclosure fan)

Recommended products

When you need more cooling power, forced ventilation steps in. You use fans to create forced convection, which moves heat out of electrical enclosures faster than natural airflow. Linkwell’s fan filter units combine strong airflow with dust and moisture filtration, keeping your electronics safe. These units use energy-efficient motors and advanced filters, so you get up to 50% energy savings compared to traditional forced ventilation systems. ECM fans maintain airflow even when filters clog, which means you get reliable cooling and lower energy bills. Forced convection works well with heatsinks, boosting heat transfer and protecting sensitive parts.

Note: Regular filter changes keep your forced ventilation system running smoothly and help maintain optimal cooling.

Cabinet Air Conditioner Applications

Recommended products

If you face high heat loads or extreme environments, cabinet air conditioners offer the best solution for cooling electrical enclosures. These systems use closed-loop refrigerant cycles to maintain precise internal temperatures. You keep dust, moisture, and contaminants out, which protects your electronics and extends their lifespan. Unlike passive cooling, enclosure air conditioning lets you control temperatures below ambient levels. You get stable performance even in harsh outdoor or industrial settings. Linkwell’s cabinet air conditioners use smart controls and inverter technology, so you save energy and reduce maintenance.

Block Quote: Cabinet air conditioners deliver consistent cooling, reduce overheating risks, and improve reliability for mission-critical electrical enclosures.

Combining Cooling Mechanisms

You can combine multiple cooling methods to get the best results. Pairing heatsinks with fans increases surface area and boosts forced convection. Some enclosures use liquid cooling for high-power applications, but this adds complexity and cost. When you mix passive and active cooling, you balance reliability, efficiency, and performance. You should choose the right combination based on heat load, enclosure size, and ambient conditions. Linkwell’s solutions let you customize your cooling strategy for any electrical enclosure.

- Combining cooling mechanisms improves heat dissipation and temperature control.

- Heatsinks work well with forced convection fans for delicate electronics.

- Liquid cooling suits dense or high-power enclosures but needs careful design.

- More cooling methods mean higher complexity and maintenance, so plan accordingly.

Tip: Always match your cooling method to your enclosure’s needs for the best protection and efficiency.

Selection Criteria and Safety

Heat Load and Environmental Factors

When you start choosing the right cooling method for your electrical enclosures, you need to look at several factors. First, figure out the total heat load inside your enclosure. This means adding up the heat from all your electrical components and considering how much heat comes from outside, like sunlight or nearby machines. If you want to keep your enclosure safe, you should keep the temperature below critical levels, usually around 35°C.

Here’s a table to help you see what matters most:

| Factor | Description |

|---|---|

| Internal Heat Load | Add up the heat from all electrical parts to size your cooling system and keep things below critical temperatures. |

| Ambient Temperature | Indoor setups might use natural airflow, but outdoor or hot areas need active cooling like air conditioners. |

| Solar Exposure | Direct sunlight or nearby heat sources add extra heat, so you may need insulation or shading. |

| Humidity & Condensation | High humidity can cause condensation and damage. Use heaters with cooling to manage moisture. |

| Contaminants | Dust or chemicals can harm electronics. Closed-loop cooling keeps air clean inside. |

| Water Exposure | If your enclosure faces rain or washdowns, use sealed, corrosion-resistant cooling systems. |

You can also use tools that calculate heat load, like RiTherm, to help you pick the most efficient cooling method. These tools consider heat, ambient conditions, and even altitude, so you get the best thermal management for your setup.

Tip: Always check your enclosure’s location and environment before picking a cooling solution. This helps you avoid overheating and keeps your system reliable.

Reliability and Compliance

You want your cooling system to work every time, no matter where you install it. Reliability means your thermal management keeps your electrical enclosures safe and running smoothly. International standards like IEC, NEMA, UL, and CSA set the rules for enclosure safety and cooling system reliability. For example, NEMA Type 4 and 4X enclosures protect against water, dust, and corrosion. UL and CSA certifications show that your cooling products meet strict safety and performance standards.

Linkwell’s cabinet air conditioners and fan filter units follow these standards. You get products tested for reliability and compliance, so you don’t have to worry about failures or unsafe conditions. When you choose certified cooling systems, you know your thermal management will protect your electrical equipment in any environment.

Note: Always look for UL, CE, or RoHS marks on your cooling products. These show the manufacturer cares about safety and reliability.

Safety Considerations

Safety comes first when you manage heat in electrical enclosures. You need cooling systems that prevent overheating, fires, and electrical failures. Certifications like UL 508A and UL 484 make sure your cooling products meet national codes. If you work in hazardous locations, you need closed-loop cooling and purge systems to keep out dangerous gases and prevent ignition risks.

Here are some safety tips for thermal management:

- Use thermostats to control temperature and avoid overheating.

- Pick enclosures with the right rating for your environment (NEMA 4X for wet or corrosive areas).

- Make sure your cooling products have agency approvals and safety interlocks.

- Regularly inspect and maintain your cooling systems to catch problems early.

Linkwell’s solutions meet international safety standards and offer reliable thermal management for all types of electrical enclosures. You get peace of mind knowing your equipment stays protected.

Application Scenarios

Indoor and Outdoor Enclosures

You face different cooling challenges depending on where you install your electrical enclosures. Indoor enclosures usually sit in controlled environments. You can rely on passive cooling or simple fan filter units to manage heat. These enclosures often use thinner materials and don’t need heavy protection against weather. Outdoor enclosures deal with moisture, dust, solar radiation, and big temperature swings. You need closed-loop cooling systems like cabinet air conditioners or air-to-air heat exchangers to keep heat and contaminants out. Outdoor setups must handle solar gain and environmental hazards, so sealed and active cooling systems become essential for reliability.

Tip: Outdoor electrical enclosures need robust climate control and surge protection to keep sensitive equipment safe from harsh weather and contaminants.

Common cooling challenges for outdoor applications include high ambient temperatures, solar load, and the need to maintain NEMA ratings for protection. You also need to size air conditioners properly to avoid rapid cycling and extend equipment life.

Industry-Specific Solutions

Every industry brings its own cooling requirements for electrical enclosures. In telecommunications and industrial automation, you protect sensitive electronics with sealed cooling systems like heat sink coolers and thermoelectric units. The energy sector, including wind and power conversion, demands specialized solutions for high heat loads and tough environments. Manufacturing plants often use forced-air ventilation or heat sinks to keep control panels cool in dusty, hot spaces. Medical device makers rely on custom thermal management to protect heat-sensitive reagents. Battery energy storage systems need closed-loop air conditioning to maximize reliability.

| Industry Sector | Cooling Solution Types | Key Applications |

|---|---|---|

| Telecom & Automation | Sealed cooling, heat sinks | Protect sensitive electronics |

| Energy | Robust, custom cooling | Manage high heat loads |

| Manufacturing | Forced-air, heat sinks | Control panels, CNCs |

| Medical | Custom thermal management | Blood analyzers |

| Energy Storage | Closed-loop AC | Portable power systems |

Linkwell Product Integration

You can match Linkwell products to almost any electrical enclosure application. Linkwell offers modular cooling solutions that fit cabinet size, heat load, and installation needs. Fan filter units and roof fan filters provide flexible mounting for wall, door, or roof setups. These units optimize airflow, pulling in cool air and pushing out hot air to prevent overheating and moisture buildup. Advanced features like thermostats, filters, and protective grills boost cooling performance and reliability. Smart controls let you monitor temperature and adjust settings remotely. Cabinet air conditioners deliver closed-loop cooling, protecting sensitive components from dust, humidity, and external heat. Customers report longer fan life, cleaner filters, and big drops in downtime after installing Linkwell cooling products. You get quick installation, reliable operation, and easy maintenance, making Linkwell a trusted choice for electrical enclosure cooling.

Block Quote: Linkwell’s cooling solutions help you keep your electrical enclosures safe, efficient, and ready for any application—indoors or outdoors.

Understanding the four main heat transfer types—conduction, convection, radiation, and phase change—helps you pick the right strategy for your enclosure. When you use Linkwell’s cabinet air conditioners and fan filter units, you get proven reliability and safety. Just look at the difference:

- Choose your solution by checking the environment, calculating the load, and thinking about future needs.

- Reach out to Linkwell for a custom plan that keeps your equipment safe and running strong.

FAQ

What is the most common way to cool electrical enclosures?

You usually rely on conduction convection for most enclosures. Fan filter units help move heat energy out quickly. For higher heat loads, you might need cabinet air conditioners. Always match your cooling method to your enclosure’s needs.

How do I know if my enclosure needs active cooling?

If you notice hot surfaces or see equipment shutting down, you probably need more than passive cooling. Use a thermal calculator to check your heat load. When in doubt, add a fan or air conditioner for extra protection.

Can I combine different heat transfer types in one enclosure?

Absolutely! You can mix conduction, convection, and even phase change cooling. For example, pair a heatsink with a fan or add PCMs for extra stability. Combining methods gives you better control over heat energy.

How often should I replace filters in fan filter units?

Check your filters every 1–3 months if you work in dusty or outdoor areas. In clean rooms, you can wait 4–6 months. Clean filters keep heat transfer mechanisms working at their best.

Are Linkwell cooling products safe for outdoor use?

Yes! Linkwell designs cabinet air conditioners and fan filter units with IP54/IP65 ratings. You get protection from dust, water, and harsh weather. These products keep your electrical enclosures safe and cool, even outside.