Custom CNC Electrical Enclosure Manufacturer in China

CNC Electrical Enclosure is designed to protect sensitive electrical components in control cabinets, telecom signal cabinets, and industrial panels. At Linkwellelectrics, we manufacture durable enclosures and offer tailored supply solutions. Contact us today for your project needs.

Linkwell Electrics - Your Trusted CNC Electrical Enclosure Manufacturer from China

Certified quality with ISO 9001 and CE compliance

Corrosion-resistant steel and aluminum construction

Flexible sizing with modular design for easy upgrades

Reliable thermal management with advanced cooling options

Choosing us means benefiting from strict quality control, reliable delivery schedules, and market-driven pricing. We combine engineering expertise with efficient manufacturing to give you an edge in wholesale distribution and large-scale projects.

Global Partnership

Electrical Enclosure By Type

As a trusted supplier of CNC Electrical Enclosure, we provide complete services including product sourcing, bulk packaging, global shipping, and technical support. We ensure cost-effective solutions while maintaining high industry standards. Reach out now for a custom quote.

NEMA 1

The NEMA 1 enclosure provides basic protection for indoor CNC applications, guarding against accidental contact with electrical components. It is cost-effective, durable, and widely used in control panels and machinery.

IP65

An IP65 enclosure ensures complete dust-tight protection and resistance to low-pressure water jets, making it ideal for CNC electrical systems in harsh environments. It guarantees equipment safety, reliability, and long-lasting performance.

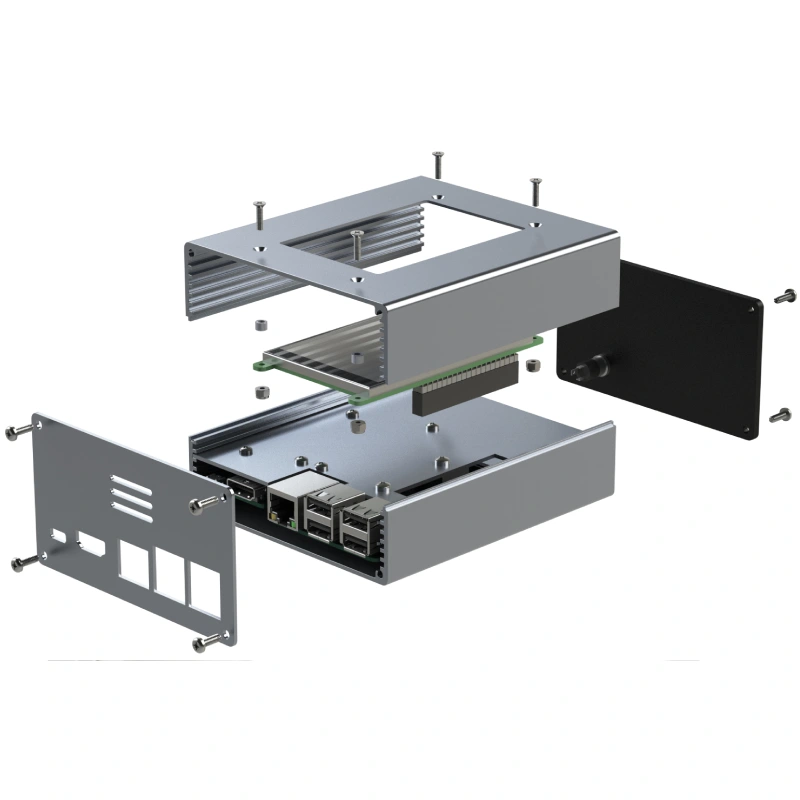

Aluminum Electrical Enclosure

Aluminum electrical enclosures offer lightweight yet strong housing for CNC systems, with excellent corrosion resistance and heat dissipation. They are perfect for outdoor or industrial environments requiring durable and efficient protection.

CNC Electrical Enclosure Key Parts

Thermostat and Hygrostat

Types: Mechanical, electronic

Performance: Regulates temperature and humidity

Durability: Long-lasting under varied climates

Integration: Easy wiring to control systems

Fan and Filter

Types: Axial, centrifugal

Performance: Improves airflow, dust control

Durability: High-performance bearings, washable filters

Integration: Mountable on enclosure panels

Air Conditioner

Types: Surface, inset, top-mount

Performance: Maintains precise cooling

Durability: Designed for continuous duty cycles

Integration: Fits cabinets and telecom racks

Enclosure Lamp

Types: LED, fluorescent

Performance: Provides interior lighting

Durability: Shock and vibration resistant

Integration: Clip or screw mount installation

Enclosure Heater

Types: PTC, fan heater

Performance: Prevents condensation buildup

Durability: Heat-resistant construction

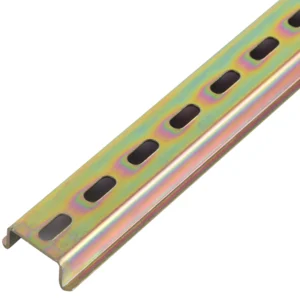

Integration: DIN rail mountable

Terminal Blocks

Types: Screw, spring clamp

Performance: Ensures reliable wiring connections

Durability: Flame-retardant insulation

Integration: DIN rail compatible

Control Transformer

Types: Single-phase, three-phase

Performance: Adjusts voltage for devices

Durability: Copper windings, epoxy-coated

Integration: Panel or rail mounted

CMS Cable Management

Types: Slotted ducts, brush strips

Performance: Organizes and protects cables

Durability: ABS or polycarbonate build

Integration: Fits racks or enclosures

Push Button

Types: Momentary, latching

Performance: Controls power or functions

Durability: IP-rated, impact-resistant

Integration: Front-panel installation

Certificate

More Manufacturing Process for Linkwell CNC Electrical Enclosure

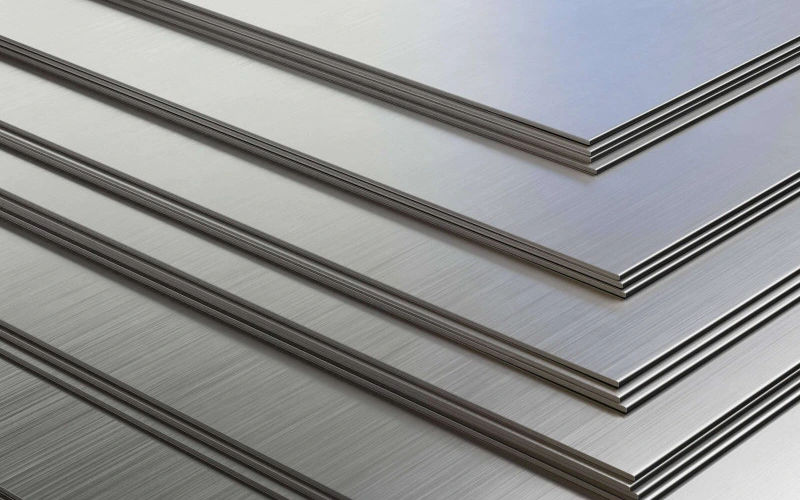

Precision Material Selection

We begin with premium steel or aluminum sheets, carefully inspected for thickness, strength, and corrosion resistance. This ensures every CNC electrical enclosure starts with reliable, long-lasting raw materials.

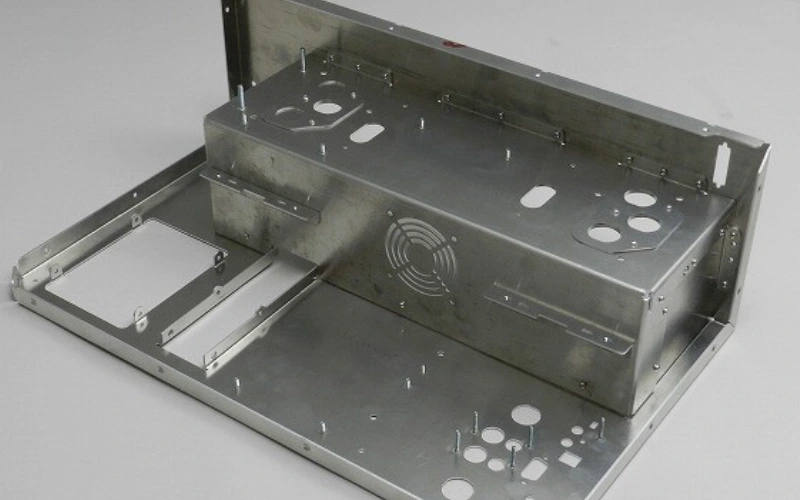

Advanced CNC Fabrication

Using state-of-the-art CNC machines, we cut, bend, and weld with extreme precision. This guarantees accurate dimensions, smooth finishes, and structural integrity for both standard and custom enclosure designs.

Surface Treatment & Assembly

Each enclosure undergoes powder coating, sealing, and rigorous quality checks. Components like hinges, locks, and gaskets are assembled, ensuring final products meet strict IP/NEMA standards for global applications.

Customize Your CNC Electrical Enclosure

Quality & Reliability

We ensure enclosures meet IP55/IP66 protection standards for harsh environments.

Our production process follows ISO-certified systems ensuring consistent product quality.

Each enclosure is tested for durability before shipment to reduce buyer risk.

Customization & Flexibility

We offer tailored dimensions, colors, and cooling solutions to fit client needs.

Buyers can request branding, cut-outs, or modular designs for specific industries.

Our customization ensures cost savings and better integration into projects.

Cost & Efficiency

Bulk orders receive competitive pricing without compromising performance.

Efficient logistics and fast lead times minimize downtime for distributors.

We help wholesalers reduce replacement costs with long-lasting enclosures.

After-Sales & Market Support

We provide technical documentation and installation guidance.

Our service team supports distributors with global market insights.

Reliable warranty and spare parts availability ensure long-term trust.

What is CNC Electrical Enclosure? How Does It Work?

A CNC Electrical Enclosure is a protective housing used to safeguard electrical equipment, wiring, and control systems in industrial, telecom, and automation applications. It shields sensitive components from dust, moisture, heat, and accidental contact, ensuring safe and reliable operation.

How does it work?

The enclosure functions as a controlled environment for electronics. It begins with robust construction, usually from powder-coated steel or stainless steel, designed to withstand physical impact, corrosion, and environmental hazards. The enclosure is sealed with gaskets and fitted with IP-rated doors that block out dust and water ingress.

Inside, the enclosure contains mounted components such as PLCs, relays, and transformers. Proper organization is achieved through DIN rails and cable management systems, which secure wiring and improve serviceability. For power distribution, terminal blocks and control transformers are installed to regulate and route electricity safely.

To maintain optimal operating conditions, the enclosure integrates thermal management systems. This may include fans, filters, heaters, or even full air conditioning units. These devices ensure that equipment stays within safe temperature and humidity levels, preventing overheating, condensation, and corrosion.

Safety is enhanced through grounding provisions, lockable doors, and push-button controls that allow operators to manage systems safely. Internal lighting supports maintenance work, while protective coatings extend the life of the enclosure even in outdoor or harsh industrial settings.

In operation, the enclosure allows electrical equipment to perform efficiently and safely, with minimal risk of environmental damage or system failure. By providing mechanical strength, climate stability, and easy integration of components, the CNC Electrical Enclosure becomes a vital part of any modern electrical or telecom infrastructure.

What are the Benefits of CNC Electrical Enclosure?

Enhances equipment safety and performance reliability

Reduces downtime with efficient cooling and organization

Lowers maintenance costs with durable, certified design

Customer Testimonials

FAQ of CNC Electrical Enclosure

What materials are CNC Electrical Enclosures made of?

Most enclosures are built from powder-coated steel, stainless steel, or aluminum. These materials provide excellent resistance to corrosion, heat, and mechanical impact. For telecom or outdoor use, additional weatherproof coatings are applied.

How do CNC Electrical Enclosures ensure safety?

They are designed with IP ratings (IP55, IP66) to guard against dust and water. Many models feature locking systems, thermal management (fans or AC units), and grounding provisions to protect operators and equipment.

Do CNC Electrical Enclosures support large-scale projects?

As a manufacturer, we supply in bulk for control cabinets, telecom base stations, and automation lines. Wholesalers benefit from competitive pricing, reliable delivery, and technical support.

How do I select the right CNC Electrical Enclosure?

Selection depends on factors like environment (indoor/outdoor), IP rating, size, material, and cooling requirements. Our engineers provide recommendations to help clients choose the best option for their projects.

What industries commonly use CNC Electrical Enclosures?

Industries include telecommunications, industrial automation, energy distribution, and data centers. These sectors need secure enclosures to protect sensitive equipment and ensure uninterrupted operations.

What services does Linkwellelectrics provide as a manufacturer?

We offer design consultation, custom fabrication, bulk production, global shipping, technical documentation, and warranty support. Our services are designed to help distributors succeed in their markets.

How does Linkwellelectrics ensure product quality?

We comply with ISO 9001, CE, and RoHS certifications. Every enclosure undergoes strict quality checks, including mechanical stress testing, corrosion testing, and electrical safety inspections.

What is the delivery time for bulk orders?

Typically, lead time is 3–5 weeks, depending on customization. We prioritize large orders for distributors and guarantee on-time delivery with global logistics support.

What is the purpose of a CNC electrical enclosure and how is it connected to FFUs and air conditioning units?

A CNC electrical enclosure safeguards machine controls and wiring while using DIN rail electronic enclosures for organized mounting. It often connects to network switch cabinets and telecom shelters for communication interfaces. Equipped with control cabinet air conditioners, FFUs, and enclosure air conditioning units, it ensures stable temperatures, dust-free airflow, and longer machine life.

All-in-one CNC Electrical Enclosure Solutions for Your Project

We specialize in custom-built CNC Electrical Enclosure with flexible options such as size, materials, cooling systems, wiring layout, and branding. Customization helps reduce downtime, optimize costs, and improve market competitiveness with faster delivery and consistent quality.