Cooler Fan Assembly

Cooler Fan Assembly Solutions for Control Cabinets and Electrical Enclosures

Our Cooler Fan Assembly is designed for control cabinets, telecom enclosures, and electrical boxes. As a trusted manufacturer, Linkwellelectrics provides quality products, custom solutions, and reliable support for global buyers.

Key Features of Our Cooler Fan Assembly

Designed for wholesalers and large-scale buyers, our Cooler Fan Assembly combines high performance with easy integration, ensuring your cabinets stay cool and efficient in demanding environments.

High Cooling Efficiency

Maximized airflow keeps equipment at safe operating temperatures, protecting sensitive electronics from overheating and reducing unexpected downtime.

Low Noise Design

Quiet performance ensures cabinets can be installed in offices, factories, or telecom environments without disturbing nearby staff.

Durable & Reliable

Built with strong materials and strict quality standards, ensuring long-lasting performance even in harsh industrial conditions.

Energy Saving

Optimized motor and blade design lowers power consumption, helping large facilities save on operating costs.

Easy Installation

Simple mounting system designed to fit standard cabinet cutouts, reducing labor time during installation.

Our Cooler Fan Assembly Series

Our Cooler Fan Assembly Series offers durable, energy-efficient cooling solutions for control cabinets and enclosures, ensuring reliable airflow, easy installation, and long-term performance for industrial applications worldwide.

FU Series

Multiple size options with built-in nuts ensure secure mounting; optional air duct design boosts cooling performance and airflow efficiency.

LK32 Series

Quick-release buckle system allows easy maintenance; optional power indicator clearly shows real-time operating status.

LK66 Series

Straight-line grill pattern promotes smooth air circulation and significantly improves cabinet ventilation.

FF Series

Durable UV-resistant PC alloy construction; optional corrugated filter mat ensures high-level dust protection for sensitive equipment.

FK55 Series

Ultra-thin cover fits compact enclosures; elegant curved-line grill adds a modern look while maintaining airflow efficiency.

Global Partnership

Cooler Fan Type

Our Cabinet Cooler Fan product range meets the cooling needs of various industries, ensuring stable performance and reliable protection for your electrical cabinets.

Compact Axial Fans

Lightweight and efficient, ideal for small enclosures requiring focused airflow.

Propeller Axial Fan

High-capacity airflow, perfect for large cabinets with heavy-duty cooling needs.

Vane Axial Fan

Balanced pressure and airflow, designed for complex cabinet cooling applications.

Technical Specifications

We meet global industry standards with customizable airflow (CFM), voltage, noise level, IP rating, and filter grade.

-

FK5522 Dust-proof ventilation filter for shutters

-

FK5521 Series Fan And Filter

-

FK5523 Cooling fan and filter

-

FK5525 Series Fan And Filter

-

FK5524 Multi specification filter cooling exhaust fan

-

FK5526 Imported ultra-thin ventilation filter group

-

FK5527 Cabinet filter cooling fan electrical control cabinet

-

FK5528 Dustproof plastic shutter axial flow fan

-

FK5529 Cabinet power distribution cabinet shutter fan and filter

-

LK3237 Filter Fans For Enclosure Cooling

-

FU95 Power Efficient Fans

-

Low Profile Cooler

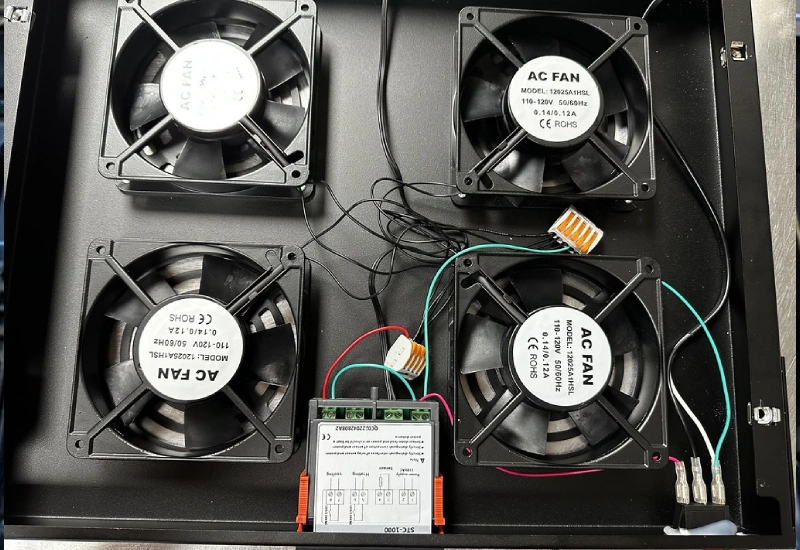

Cooler Fan Assembly Key Components

Front Filter

Prevents dust and debris from entering the cabinet.

Filter Media

Ensures consistent air filtration, extending component life.

Filter Back

Provides secure placement and easy replacement of filter elements.

Fan

The core unit delivering strong airflow for cooling performance.

Finger Guard

Safety feature preventing accidental contact with blades.

Applications

Our Cabinet Cooler Fan Assembly is used in industries where stable cooling is critical.

Telecom Industry

Reliable cooling for signal cabinets to ensure uninterrupted network service.

Power Distribution

Keeps electrical cabinets safe, reducing risk of overheating and power failures.

Automation Systems

Maintains stable control cabinet environments, ensuring smooth machine operations.

Data Centers

Supports cooling in server racks, enhancing equipment lifespan and performance.

Certifications & Clients

Our fans comply with international standards such as CE, UL, and RoHS, ensuring quality and safety.

Our clients include leading manufacturers and distributors worldwide, trusting Linkwellelectrics for long-term supply partnerships.

Why Choose Linkwell?

At Linkwellelectrics, we focus on creating durable and energy-efficient cooler fans that meet international quality benchmarks. Every fan we manufacture is tested against strict standards and certified under CE, UL, and RoHS, ensuring safe and reliable operation across industries.

Our global customers trust us not just for product quality, but also for our ability to deliver quickly and adapt to their unique requirements. Whether you need custom sizes, branding, or bulk orders, we provide tailored solutions with fast shipping and full after-sales support. With us, you get more than a product—you get a long-term partner dedicated to your business success.

FAQs

What is a Cooler Fan Assembly and why is it important?

A Cooler Fan Assembly is a complete system that includes a fan, protective grill, and filter. It is installed in control cabinets, electrical enclosures, and telecom boxes to maintain safe operating temperatures. Without it, overheating can cause failures, reduce equipment lifespan, and increase costly downtime.

How does a Cooler Fan improve cabinet performance?

By bringing in cool air and exhausting hot air, a Cooler Fan keeps sensitive electronics within safe temperature limits. This ensures consistent performance of control systems, servers, or telecom cabinets, and helps businesses avoid overheating risks that could lead to production stops or network failures.

Are Cooler Fan Assemblies energy-efficient?

Yes. Modern cooler fans are designed with aerodynamic blades and optimized motors that deliver strong airflow with minimal energy use. This not only protects equipment but also lowers electricity bills for factories, data centers, and telecom operators who run cabinets 24/7.

How often should filters be cleaned or replaced?

Most filters need cleaning or replacement every 3–6 months, depending on environmental dust levels. In dusty industrial areas, filters may need more frequent attention. Regular maintenance ensures maximum airflow efficiency and keeps internal equipment free from dust buildup.

Can Cooler Fans reduce operational noise?

Yes, many models are engineered with low-noise technology. This makes them suitable for settings like offices, hospitals, or control rooms where quiet operation is critical, while still maintaining excellent cooling capacity.

What materials are typically used in Cooler Fan Assemblies?

High-quality cooler fans use durable plastics such as UV-resistant PC alloy, combined with corrosion-resistant metals and reliable filter materials. These materials meet international safety and environmental standards, ensuring long-lasting use in harsh industrial conditions.

What is your production capacity for Cooler Fan Assemblies?

We operate advanced manufacturing lines capable of handling large-scale bulk orders. This ensures wholesalers and big brands receive consistent quality and on-time delivery, even during peak demand.

Do you provide technical support and after-sales service?

Yes. We believe long-term cooperation requires more than just selling products. Our technical team provides installation guidance, troubleshooting support, and quick responses to customer inquiries, ensuring smooth operation after purchase.

Contact & Inquiry

Contact us today for detailed product information, quotes, or expert technical support. Simply complete the form with your name, email, company, country, and inquiry, and our team will get back to you quickly. You can also connect with us directly via WhatsApp, email, or phone for fast and reliable assistance.