Do you struggle with keeping your electrical enclosures or control cabinets cool? Many face challenges like hot spots, poor air movement, and harsh environments.

- Inadequate air circulation often creates isolated temperature build-up, which can cause system malfunctions and shorten component life.

- Poor ventilation is common, especially in industrial spaces where panels sit in tight or poorly ventilated areas.

- Dust and humidity can lead to condensation, raising the risk of short circuits and damaging key components.

Choosing the right custom cooling fans helps you prevent these issues and protect your equipment.

Key Takeaways

- Understand your cooling needs by calculating the heat load from your equipment. This helps prevent overheating and ensures safe operation.

- Consider the size and mounting options of your enclosure. Proper fan placement is crucial for effective airflow and maintenance.

- Select fans based on environmental conditions. Choose models with appropriate IP ratings to protect against dust and moisture.

- Calculate airflow requirements using specific formulas. Ensure your fan can handle the necessary flow rate and static pressure for optimal performance.

- Prioritize reliability and maintenance. Regular inspections and cleaning extend the lifespan of your cooling fans and protect your investment.

Cooling Needs

When you select a custom cooling fan, you first need to understand your system’s cooling needs. This step helps you avoid overheating and keeps your equipment running safely.

Heat Load

Start by figuring out how much heat your enclosure produces. Heat load comes from two main sources:

- Internal heat load: This is the heat created by the electronics inside your enclosure.

- External heat load: This is the heat gained or lost through the enclosure walls, which depends on where you place the enclosure.

You can estimate your total cooling requirements by following these steps:

- Check the power consumption of all components inside the enclosure. About 10–15% of this power turns into heat.

- Measure the temperature difference between the inside and outside of the enclosure.

- Add up the known heat generation of each device (in watts or BTU/h).

Different environments need different NEMA ratings. For example, outdoor, washdown, or hazardous locations require special protection. Linkwell’s fan filter units and electrical enclosure fans work well in many industrial settings, helping you manage both internal and external heat loads.

Airflow & Temperature

Once you know your heat load, you need to set your airflow and temperature targets. Proper airflow ensures your system stays within safe temperature limits. You can calculate airflow using these formulas:

- For degrees Fahrenheit:

Airflow (CFM) = BTU/hr / (1.08 × ΔT°F) - For degrees Celsius:

Airflow (CFM) = BTU/hr / (1.95 × ΔT°C)

A typical temperature rise is 10°C or 18°F. Add a 25% safety margin to your total cooling requirements for extra protection.

Tip: Many electrical components, like power supplies and drives, operate safely up to 60°C (140°F). Devices that generate more heat need careful thermal management.

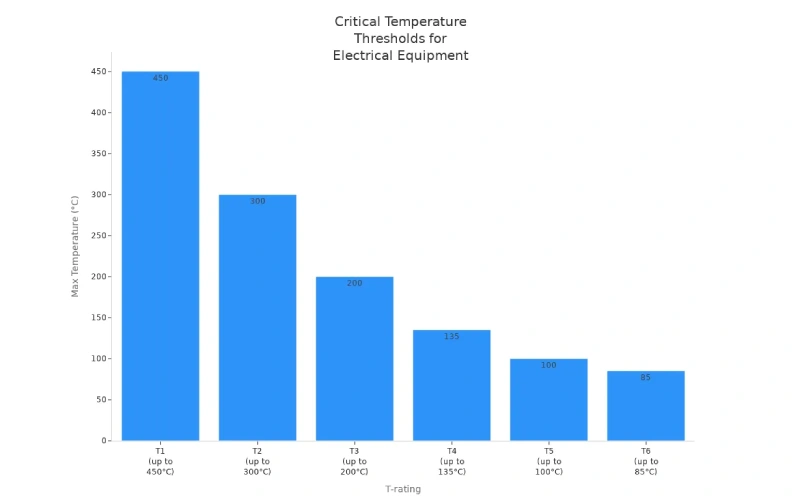

Here are common temperature thresholds for electrical equipment:

| Temperature Rating (T-rating) | Description |

|---|---|

| T1 (up to 450 °C) | High ignition risk environments |

| T2 (up to 300 °C) | Many industrial applications |

| T3 (up to 200 °C) | Moderate ignition risk |

| T4 (up to 135 °C) | Lower ignition risk |

| T5 (up to 100 °C) | Less hazardous environments |

| T6 (up to 85 °C) | Very low ignition risk environments |

When you choose a Linkwell fan filter unit or electrical enclosure fan, you match your cooling capacity to your system’s needs. This approach helps you meet safety standards and keeps your equipment reliable.

System Constraints

Space & Mounting

When you choose a cooling fan, you must consider the size and shape of your enclosure. The available space inside the cabinet determines where you can mount the fan and how much airflow you can achieve. A compact enclosure limits your options and requires careful planning to avoid blocking airflow or making maintenance difficult.

Here is a table showing standard space constraints for industrial enclosures:

| Description | Dimensions (W x H x D) |

|---|---|

| Maximum internal space for devices | 413 mm x 470 mm x 152 mm |

| Maximum allowable space (brackets/cables) | 470 mm x 470 mm x 152 mm |

| Primary internal PC mounting plate | 356 mm x 457 mm |

| Secondary service panel maximum size | 381 mm x 368 mm x 152 mm |

You should also think about mounting options. The way you install the fan affects how well it cools your equipment. For example:

- Wall-mounted exhaust fans pull air toward them, which can create dead zones.

- Wall-mounted intake fans push air into the enclosure and may disrupt natural airflow.

- Roof-mounted exhaust fans help remove hot air by promoting vertical airflow.

Tip: If your PC has an integrated cooling fan, you may not need an internal circulating fan. If you skip the internal fan, mount the PC as low as possible in the enclosure for better cooling.

Linkwell offers fan filter units and electrical enclosure fans that fit various mounting styles. You can select models designed for tight spaces or larger cabinets, ensuring proper airflow and easy installation.

Environment

The environment around your enclosure plays a big role in fan performance. High temperatures, humidity, and corrosive substances can damage fan components and reduce their lifespan. You need fans built with materials that withstand these conditions.

| Environmental Factor | Impact on Fan Performance |

|---|---|

| Temperature | Fans must handle high heat without losing efficiency. |

| Humidity | Moisture can shorten the life of fan motors and bearings. |

| Corrosive Substances | Fans need corrosion-resistant materials to keep working in harsh environments. |

IP ratings help you choose fans that resist dust and water. The first digit of the IP rating shows protection against solids, and the second digit shows protection against liquids. For example, an IP55 rating means the fan has limited dust ingress and can handle low-pressure water jets. This rating improves reliability in dusty or moist settings.

Linkwell’s IP-rated fan filter units and weatherproof enclosure fans give you peace of mind. You can trust these products to perform well in challenging environments, keeping your equipment safe and cool.

Calculate Airflow

Use Equations

You need to calculate the required flow rate and static pressure before choosing a cooling fan. Start by estimating the heat produced inside your enclosure. Use the following formula to find the necessary flow rate in cubic feet per minute (CFM):

Airflow (CFM) = BTU/hr / (1.08 × ΔT°F)

This equation helps you determine how much air you need to move to keep your equipment cool. If you measure in metric units, use:

Airflow (m³/h) = Qv / (F × ssT)

Here is a table that explains the variables:

| Variable | Description |

|---|---|

| V | Required volumetric air flow (m³/h) |

| F | Volume (m³) of air needed per °C change for each Watt-hour of heat transfer |

| Qv | Heat generated by equipment |

| ssT | Difference between internal requirement and external ambient |

You must also consider static pressure. Static pressure measures the resistance to airflow caused by filters, heatsinks, or tight spaces. High static pressure fans push air through obstacles, keeping the flow rate steady. Use this equation to relate heat transfer and flow rate:

- Q̇ = 1.0746 × ΔT × ṁ

- Q̇: Rate of heat transfer

- ΔT: Temperature difference

- ṁ: Flow rate of air (CFM)

Tip: Always check the static pressure rating of your fan. If your enclosure uses filters or has dense wiring, you need a fan that can overcome higher static pressure.

Apply to Linkwell Products

Linkwell offers fan filter units and electrical enclosure fans designed for efficient airflow in industrial settings. You can match your calculated flow rate and static pressure needs to their product specifications. For example, Linkwell’s fan filter units provide airflow capacities from 600 to 1200 m³/h. These units maintain reliable flow rate even when filters increase static pressure.

Static pressure plays a key role in high-density equipment. Linkwell’s static pressure fans excel in cabinets with filters and heatsinks. You avoid airflow loss and keep your system cool. Undersized filters increase static pressure and reduce flow rate. Oversized filters may cause system imbalance.

Here is a comparison table of Linkwell’s specifications and industry standards:

| Specification | Linkwell Product | Industry Standard |

|---|---|---|

| Efficiency | F9 | Meets/exceeds |

| Filtration Grade | ULPA Filter | Meets/exceeds |

| IP Class | IP54, IP55, IP56 | Meets/exceeds |

| Noise Level | 46-50 dB(a) | Acceptable range |

| Operating Temperature Range | -30 to +70 °C | Standard range |

You achieve efficient airflow by selecting a fan with the right flow rate and static pressure rating. Linkwell’s products help you maintain cooling performance, even in tough environments.

Custom Cooling Fans Selection

Select the Right Fan

When you need to select the right fan for your application, you must focus on several important criteria. Custom cooling fans give you the flexibility to match your system’s exact needs. You should start by identifying your cooling goals and the environment where your equipment operates.

You want a fan that meets safety standards, fits your budget, and offers customization options. These priorities help you avoid problems and keep your system running smoothly.

Here is a table showing the top criteria to consider when selecting a fan or blower for industrial use:

| Criteria | Description |

|---|---|

| Safety and Compliance | Make sure your fan meets industry standards and local regulations. |

| Budget Considerations | Look at the total cost of ownership, not just the purchase price. |

| Customization Options | Choose a manufacturer that can customize features for your business needs. |

Custom cooling fans let you select a fan or blower with features that match your application. You can choose fans with variable speed, advanced controls, and special mounting options. These choices help you manage airflow, reduce hotspots, and improve overall system performance.

Compare Fan Types

You have many options when selecting a fan or blower for your enclosure. Linkwell offers fan filter units, electrical enclosure fans, and computer chassis fans. Each type has unique strengths for different environments.

- Fan Filter Units: These custom cooling fans combine a fan and filter to keep dust and moisture out. You can select a fan for indoor or outdoor use. Indoor filtered fans maintain positive pressure and cool the enclosure. Outdoor filtered fans have lockable covers and sloped designs to protect against harsh weather.

- Electrical Enclosure Fans: These fans focus on moving air efficiently inside control cabinets and telecom boxes. You can select a blower with weatherproof housing for outdoor use. These fans work well in high-temperature and high-humidity environments.

- Computer Chassis Fans: These custom cooling fans provide high airflow and low noise levels for IT equipment and industrial computers. You can select a fan with PWM speed control for adjustable performance. Over 70% of engineers now use PWM devices to improve thermal management. PWM technology can reduce power consumption by up to 20% compared to traditional models.

Here is a table comparing the main types of custom cooling fans:

| Fan Type | Characteristics | Use Case |

|---|---|---|

| Plastic Filtered Fans | Quiet operation, easy filter maintenance, removes harmful particles from air. | Use in clean indoor environments. |

| Metal Filtered Fans | Durable, customizable, robust filter materials. | Use in areas needing more strength and custom aesthetics. |

| NEMA Rated Fans | Extra protection features, designed for specific conditions. | Use in both indoor and outdoor settings, depending on NEMA rating. |

Recommended products

When selecting a fan or blower, you must consider noise, efficiency, and compatibility. Custom cooling fans with low noise levels help you maintain a quiet workspace. Features like variable speed and PWM control allow you to balance noise and cooling efficiency. The demand for adaptable temperature regulation systems continues to grow. You can select a fan or blower that matches your airflow needs and fits your enclosure.

Tip: Always check compatibility. Make sure the fan’s voltage and current ratings match your power supply. Evaluate the space available for mounting. Assess the operating environment, including temperature, humidity, and dust exposure. Regulatory standards for performance, efficiency, and noise levels also matter.

Here is a table to help you compare compatibility and integration options when selecting a fan or blower:

| Factor | Description |

|---|---|

| Application Requirements | Know your cooling needs, including heat load and airflow. |

| Space Constraints | Check the fan’s size against available space. |

| Power Supply Compatibility | Match voltage and current ratings to your system. |

| Environmental Conditions | Consider temperature, humidity, and dust exposure. |

| Regulatory Standards | Follow industry standards for performance and noise. |

Custom cooling fans from Linkwell offer solutions for every application. You can select a fan or blower with the right features for your system. You improve energy efficiency, reduce maintenance, and extend equipment life. Selecting a fan or blower with advanced controls and low noise levels helps you create a reliable and quiet environment.

You can select a fan or blower that fits your needs by comparing features, compatibility, and efficiency. Custom cooling fans give you the flexibility to solve any cooling challenge.

Practical Factors

Cost & Reliability

When you choose a custom cooling fan, you want to balance performance with a reasonable cost. Industrial fans can range in price from $400 to over $10,000. The final cost depends on the size, motor type, features, and service requirements. You also need to consider installation, which averages $0.25–$0.32 per square foot.

Reliability matters just as much as cost. You should look for fans that meet strict safety and quality standards. Linkwell’s cooling fans hold certifications that include UL, cUL, CE, and ISO. These certifications show that the fans meet international safety and quality requirements.

| Certification | Compliance Standard |

|---|---|

| UL | U.S. safety standards |

| cUL | Canadian safety standards |

| CE | International safety standards |

| ISO | Quality management standards |

Regular maintenance helps you protect your investment. You should inspect fan wheels and shafts for wear or corrosion. Tighten fasteners, especially in areas with vibration. Clean the impeller and air inlet to prevent dust buildup. Replace filters as needed to keep airflow strong. Check motor and electrical parts for signs of wear. These steps help you avoid breakdowns and keep your system running smoothly.

Linkwell’s global support ensures you get reliable performance in any industrial environment. Their fans help maintain stable temperatures, prevent overheating, and support uninterrupted power distribution.

Service Life

You want your cooling fan to last as long as possible. The average service life depends on the fan type and how well you maintain it. Axial fans can last 5–10 years. Centrifugal fans may reach 8–15 years. HVLS fans often last 10–20 years.

| Fan Type | Lifespan Potential |

|---|---|

| Axial fan | 5–10 years |

| Centrifugal fan | 8–15 years |

| HVLS fan | 10–20 years |

Regular cleaning and inspections help you achieve a long service life. Linkwell’s commitment to quality control and international standards means you can trust their fans to perform reliably over time. Their customization options let you select features that match your needs, so you get the best value for your investment.

Selecting the right custom cooling fan involves several key steps. You should:

- Identify the type of fan and airflow needed for your application.

- Calculate total airflow and static pressure.

- Consider noise levels, voltage, and space constraints.

- Match fan specifications to your real-world needs for best performance.

| Factor | Description |

|---|---|

| Size | Ensure the fan fits your enclosure. |

| Airflow | Choose the right CFM for your space. |

| Noise Levels | Select low-noise models for comfort and safety. |

For expert advice or custom solutions, consult Linkwell. Matching fan specs to your needs improves reliability and efficiency.

FAQ

How do you know which fan size fits your enclosure?

Measure the available space inside your cabinet. Check the mounting dimensions in the product datasheet. Select a fan that fits without blocking airflow or access to other components.

What is the difference between an axial fan and a centrifugal fan?

| Fan Type | Airflow Direction | Best Use Case |

|---|---|---|

| Axial | Straight | General cooling |

| Centrifugal | Sideways | High static pressure |

Choose axial fans for open spaces. Pick centrifugal fans for tight or filtered enclosures.

How often should you replace the filter in a fan filter unit?

You should check the filter every 3 months. Replace it every 4–6 months in clean areas. In dusty or outdoor locations, change the filter every 1–3 months for best airflow.

Can you use Linkwell cooling fans outdoors?

Yes, you can use Linkwell cooling fans outdoors. Select models with IP ratings like IP54 or IP65. These ratings protect against dust and water, making them suitable for harsh environments.