You need to control temperature and humidity if you want to prevent condensation inside electrical enclosures. Condensation can cause big problems, like short circuits, corrosion, and even fire hazards. Here are some risks you face when moisture builds up:

- High humidity leads to condensation, which can trigger electrical malfunctions.

- Flooding and storms can damage components, increasing fire and electrocution risks.

- Corrosion weakens parts, making your system unsafe.

Reliable solutions matter. Linkwell offers trusted products that help you learn how to prevent condensation in electrical enclosures. Whether you work in a factory or handle home projects, you can use practical tips to keep your equipment safe.

Prevent Condensation in Electrical Enclosures: Key Takeaways

- Keep the temperature inside electrical enclosures steady to stop moisture from forming and damaging your equipment.

- Control humidity by using dehumidifiers or desiccants and keep it below 60% to 70% to prevent condensation.

- Seal enclosures tightly with good gaskets and check them regularly to block moisture and dust from entering.

- Use proper ventilation and airflow to remove moist air and bring in dry air, reducing the chance of condensation.

- Perform regular inspections and maintenance to spot and fix moisture problems early, protecting your equipment from corrosion and failure.

Electrical Enclosures Causes of Condensation

Temperature Fluctuations

You might notice condensation inside electrical enclosures when temperatures swing up and down. This happens a lot in places where the weather changes quickly or when equipment heats up and cools down. When warm, humid air inside the enclosure meets a cold surface, water vapor condensation forms. Even a small temperature drop can push the air inside to its dew point, causing moisture to appear on your electronics. Metal enclosures transfer heat faster, so they can cool down quickly at night and warm up fast during the day. This creates temperature variations that make condensation more likely. If you place your enclosure in direct sunlight or near heat sources, you increase the risk. Keeping a steady temperature inside helps prevent the build-up of moisture and protects your equipment.

Tip: Try to avoid placing enclosures in spots with direct sunlight or rapid temperature swings. Good ventilation and spacing between components can help keep things stable.

Humidity and Moisture

Humidity plays a huge role in condensation. When the humidity level inside your enclosure gets close to 100%, the air cannot hold any more water. If the temperature drops, water vapor turns into liquid and settles on surfaces. This is a big problem in outdoor electrical enclosures, especially during rainy or humid seasons. Even if you seal your enclosure, the air trapped inside can still hold moisture from when you closed it. Over time, repeated temperature cycles—like day and night changes—can cause condensation to form again and again. Keeping the humidity level below 60% to 70% inside your enclosure is a smart way to reduce the risk.

Poor Sealing

Poor sealing lets humid air, dust, and even water sneak into your electrical enclosures. Gaps around cable entries, worn-out gaskets, or misaligned doors all create paths for moisture. Once inside, this moisture raises the humidity level and, with temperature changes, leads to condensation. Over time, seals and gaskets can crack or lose their shape, making the problem worse. If you skip regular maintenance, you might not notice these issues until you see corrosion or equipment failure. Always check seals and replace old gaskets to keep your enclosure airtight.

Note: Regular inspections and replacing seals before they fail can save you from costly repairs and downtime.

Risks to Electrical Enclosures

Short Circuits

You might think a little moisture is harmless, but condensation inside electrical enclosures can quickly lead to trouble. When humid air sneaks in and cools down, water droplets form on wires and circuit boards. This moisture creates a path for electricity to jump where it shouldn’t, causing short circuits. In fact, humidity is often the main reason circuits get damaged—not just direct water leaks. Even if your enclosure looks sealed, condensation can still build up inside, especially when temperatures swing from hot to cold. Short circuits can trip breakers, shut down equipment, or even start fires. You want to avoid these risks by keeping your enclosures dry and well-managed.

⚡ Tip: If you notice tripped breakers or flickering lights, check for signs of moisture inside your enclosure.

Corrosion

Condensation doesn’t just cause shorts—it also eats away at your equipment over time. When water sits on metal parts, rust starts to form. This rust weakens connections and makes your devices less efficient. You might also see other types of corrosion, like galvanic corrosion on circuit boards, which happens when moisture removes protective layers and breaks tiny copper paths. Sometimes, dendritic corrosion forms, creating unwanted bridges between connections and causing your device to malfunction. All these problems start with too much condensation inside electrical enclosures. Corrosion reduces the lifespan of your gear and can lead to sudden breakdowns.

Here are the most common types of corrosion you might face:

- Rust on metal parts, which weakens connections.

- Galvanic corrosion on PCBs, breaking circuit traces.

- Dendritic corrosion, creating new paths that cause malfunctions.

Equipment Failure

When condensation and corrosion team up, your equipment doesn’t stand a chance. Moisture inside electrical enclosures can cause relays to stick, sensors to fail, and control panels to stop working. Over time, even small amounts of water can break down insulation and damage sensitive electronics. You might notice your system acting up for no clear reason—often, hidden condensation is to blame. If you ignore these warning signs, you risk costly repairs, downtime, or even total equipment loss. Keeping condensation under control helps you avoid unexpected failures and keeps your operations running smoothly.

How to Prevent Condensation in Electrical Enclosures

Condensation can sneak up on you and cause big problems inside your electrical enclosures. If you want to know how to prevent condensation in electrical enclosures, you need to focus on four main areas: temperature control, humidity management, ventilation, and sealing. Let’s break down each method so you can keep your equipment safe and dry.

Temperature Control (Heaters)

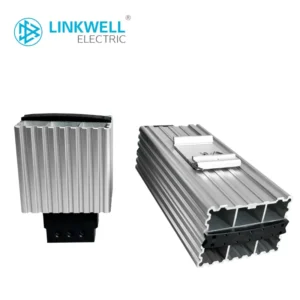

Electrical Enclosures Heaters Type

200w Enclosure Heater | Explosion-Proof Enclosure Heaters | Fan Enclosure Heaters |

Recommended products

You can stop condensation before it starts by keeping the inside of your enclosure warmer than the dew point. Heaters work best for this job. When you install enclosure heaters, you create a stable climate that keeps moisture from forming on cold surfaces. Linkwell Enclosure Heaters are designed for this exact purpose. They use thermostats to maintain the right temperature, so you don’t have to worry about overheating or wasting energy.

Here’s why heaters are so effective:

- They keep the temperature steady, which helps prevent condensation.

- Heaters with built-in humidistats turn on only when humidity rises, saving power.

- You avoid freezing and rust, which means your equipment lasts longer.

- Linkwell’s certified heaters protect your gear in harsh outdoor or factory settings.

Tip: Always install enclosure temperature and humidity controller for precise climate control. This lets you set the temperature just above the dew point, which is the best way to prevent condensation.

If you work in cold or damp environments, heaters are your first line of defense. They help you maximize uptime and reduce costly repairs.

Humidity Management (Dehumidifiers, Desiccants)

Humidity is the main reason condensation forms inside electrical enclosures. You can reduce humidity by installing electrical cabinet dehumidifier units. These devices pull moisture out of the air and keep the relative humidity below critical levels. Dehumidifiers work well in places with high humidity or temperature swings. Some models use sensors to monitor moisture and adjust automatically.

You can also use desiccants like silica gel packets. These absorb water vapor and help prevent condensation on sensitive parts. Just remember to check and replace them regularly. If you want extra protection, combine dehumidifiers with desiccants for better results.

- Dehumidifiers actively remove moisture and keep humidity low.

- Desiccants offer passive moisture control but need regular maintenance.

- Humidity-regulating systems with sensors give you real-time control.

Note: For best results, install enclosure temperature and humidity controller along with dehumidifiers. This combo gives you accurate control and fast response to changing conditions.

Linkwell offers solutions that make humidity management easy. Their products help you prevent condensation and protect your electronics from corrosion.

Ventilation and Airflow

Good airflow is key to condensation prevention. A proper ventilation system lets moist air escape and brings in fresh, dry air. You can use passive vents, like slanted louvre vents or waterproof vent plugs, to promote air movement. For larger enclosures, install fans to boost airflow and speed up evaporation.

Here’s how ventilation helps:

- It regulates temperature and reduces moisture buildup.

- Fans circulate air, making sure no area stays damp.

- Passive vents work well for small enclosures, while blower fans suit bigger cabinets.

Tip: Place vents and fans near areas where condensation is likely to form. Make sure nothing blocks airflow inside your enclosure.

Linkwell Outdoor Enclosures come with pre-mounted fans and vents, making it easy to set up a reliable ventilation system. Their certified products help you prevent condensation and keep your equipment running smoothly.

Sealing and Insulation

Proper sealing and insulation stop humid air and water from getting inside your electrical enclosures. Use high-quality gaskets, liquid rubber sealants, and epoxy coatings to close gaps around doors, cable entries, and joints. Neoprene gaskets provide a tight seal, while thermal insulation keeps the temperature steady and prevents cold spots.

| Material/Method | Purpose/Effectiveness | Notes/Details |

|---|---|---|

| Neoprene gaskets | Smooth, high-pressure sealing | Great for doors and cable entries |

| Liquid rubber sealant | Seals wire entry points | Maintains waterproof rating |

| Thermal insulation | Reduces temperature gradients | Prevents dew point formation |

| Breathable membrane vents | Allows air exchange, blocks water | Equalizes pressure, stops moisture ingress |

Insulation also helps you lower energy costs and improve safety. Polyisocyanurate foam and polyurethane work well for thermal management. When you combine proper sealing and insulation with heaters and dehumidifiers, you get the best protection against condensation.

Note: Linkwell Outdoor Enclosures use advanced sealing and insulation materials. Their products meet UL, CE, and NEMA standards, so you know your equipment is safe.

If you want to know how to prevent condensation in electrical enclosures, always check seals and insulation during regular maintenance. This keeps moisture out and helps your system last longer.

Product Solutions from Linkwell

Enclosure Heater Features

If you want to keep moisture out of your electrical enclosures, Linkwell’s Enclosure Heater gives you a smart solution. You get a heater that prevents condensation and freezing, which protects sensitive parts like relays and sensors. These heaters use energy-efficient PTC technology, so you save power while keeping your equipment safe. You can install them near the bottom of your enclosure for even heat. Automatic control is easy with built-in thermostats or hygrostats. You don’t have to worry about safety because these heaters meet CE, UL, RoHS, and ATEX certifications. You can choose from different power ratings and mounting styles to fit your needs. If you work in outdoor or humid places, these heaters help your electrical enclosures last longer.

Tip: Use a heater with a thermostat or hygrostat for automatic moisture control. This keeps your enclosure dry without wasting energy.

Outdoor Enclosure Benefits

Linkwell’s Outdoor Enclosures protect your electrical enclosures from dust, moisture, and temperature swings. You get insulation and sealing that block water and keep the inside climate stable. These enclosures come with air conditioning units that cool your equipment and prevent overheating. You don’t have to worry about downtime because the cooling system uses a closed-loop cycle, keeping dust and moisture out. You can trust these enclosures in high-humidity environments because they meet CE, UL, and ISO9001 standards. You also get energy-efficient designs that lower power use. If you need something special, Linkwell offers customization for size, material, and accessories.

- Stable cooling extends the life of your electrical enclosures.

- Insulation and sealing protect against moisture and dust.

- Custom options fit your specific needs.

- Certified for harsh conditions.

| Feature | Benefit |

|---|---|

| Air conditioning units | Prevent overheating and moisture buildup |

| Insulation & sealing | Block dust and water |

| Certifications | Ensure safety and durability |

| Customization | Tailor solutions for any environment |

Choosing the Right Product

You want the best protection for your electrical enclosures, so think about your environment and equipment. Check if your area has high humidity or big temperature changes. Look at airflow inside your enclosure to avoid hotspots. Use heaters with hygrostats if humidity rises often. Pick enclosures with high IP ratings, like IP66, to keep water out. If you need extra moisture control, add a dehumidifier or silica gel packets. Linkwell helps you customize enclosures for telecom, energy, or industrial use. You can choose lockable doors, special finishes, or extra cooling. Their expert team supports you from design to installation, making sure your electrical enclosures stay safe and reliable.

- Evaluate humidity and temperature swings.

- Choose the right IP rating for your enclosure.

- Add heaters, dehumidifiers, or cooling units as needed.

- Customize for your industry and location.

Note: Linkwell offers flexible scheduling and bulk production for large projects. You get fast delivery and expert support every step of the way.

Maintenance to Prevent Condensation

Regular Inspections

You can stop condensation problems before they start by making inspections a habit. Check your electrical enclosures before cold weather hits. This helps you spot issues early. During cold or humid days, look inside your enclosures every day or at least once per shift. If the weather changes fast or a storm rolls in, do a quick spot check. Look for water droplets, rust, or any signs of moisture. If you find anything, act right away. Early action keeps your equipment safe and dry.

Tip: Use a checklist for your inspections. This way, you never miss a step and your electrical enclosures stay protected.

Seal and Gasket Checks

Seals and gaskets are your first defense against moisture. Pick gasket materials that match your environment, like silicone or EPDM, because they resist heat and chemicals. Make sure the gasket fits snugly and covers the whole sealing surface. If you see cracks or gaps, replace the gasket right away. After you install a new seal, check it often to make sure it stays tight. Use humidity indicator cards or electronic sensors inside your enclosure to keep an eye on moisture without opening the door. If you have a lot of cables or buttons, double-check that every entry point keeps its seal. Dual gaskets on doors add extra protection.

- Always check for even compression on the gasket.

- Replace worn seals with kits from the manufacturer.

- Tighten loose fasteners to keep everything secure.

Cleaning and Upkeep

Keeping your electrical enclosures clean helps prevent condensation. Dust and dirt block vents and trap moisture. Wipe down surfaces and clear out any debris from vents or fans. Make sure drainage holes stay open if your enclosure has them. Use desiccant packs or small heaters inside sealed enclosures to control moisture. After storms or big temperature swings, check for corrosion on fasteners and conduit connections. If you spot rust or loose parts, fix them right away. Reseal any holes or knockouts to keep your enclosure’s rating and protection strong.

| Maintenance Task | How Often | What to Look For |

|---|---|---|

| Inspect seals and gaskets | Monthly/Seasonal | Cracks, gaps, or wear |

| Clean vents and fans | Monthly | Dust, blockages |

| Check for condensation | Daily/Shift | Water droplets, rust |

| Replace desiccants | As needed | Saturated or expired packs |

Note: Good cleaning and upkeep not only stop condensation but also help your equipment last longer.

You can keep condensation out of your electrical enclosures by focusing on a few key steps:

- Use proper ventilation and airflow to balance temperature and humidity.

- Choose materials and insulation that block sudden temperature changes.

- Install heaters or dehumidifiers to keep the inside above the dew point.

- Check seals and gaskets often for a tight fit.

- Inspect and clean your enclosures regularly.

Trusted solutions like Linkwell make this easy. Take a look at your setup today. If you want expert support or the right product, reach out to Linkwell for help.

FAQ

How do I know if my enclosure needs a heater?

If you see condensation, rust, or water droplets inside, you probably need a heater. Cold climates, outdoor setups, or big temperature swings make heaters a smart choice. You want to keep your electronics dry and safe.

Can I install a Linkwell enclosure heater myself?

Yes, you can. Most Linkwell heaters use DIN rail or screw mounting. The wiring is simple, but always follow the instructions. If you feel unsure, ask a qualified electrician for help.

What’s the best way to keep humidity low inside my enclosure?

You can use a dehumidifier or desiccant packs. Make sure your enclosure seals tight. Check for leaks or gaps. For extra control, try a humidity sensor with automatic fans or heaters.

How often should I check seals and gaskets?

Check seals and gaskets every month or after storms. Look for cracks, gaps, or wear. Replace them right away if you spot damage. Good seals keep moisture out and protect your equipment.

Are Linkwell outdoor enclosures good for harsh weather?

Absolutely! Linkwell outdoor enclosures have strong seals, insulation, and high IP ratings. They protect your equipment from rain, dust, and extreme temperatures. You can trust them in tough environments.

Conclusion

Maintaining stable temperature, controlling humidity, ensuring proper sealing, and improving ventilation are key to how to prevent condensation in electrical enclosures. Linkwell offers heaters, dehumidifiers, and high-quality sealing solutions to reduce short circuits, corrosion, and equipment failures, keeping your systems safe and reliable.