Custom Pwm Fan Manufacturer in China

Our PWM Fan is engineered for electrical control cabinets, telecom signal cabinets and computer cooling – durable, reliable and designed for high-volume supply. At Linkwellelectrics we manufacture directly, offer bulk orders and support your brand’s needs.

Linkwell Electrics - Your Trusted Pwm Fan Manufacturer from China

Certified quality: ISO 9001 & UL 94 V-0 ratings ensure industry-level safety and consistency.

High-performance: 4-pin PWM control allows precise speed regulation and quieter operation.

Modular design: Easily integrates into control cabinets, computer cases and telecom racks; supports simplified stocking.

Bulk-friendly: Large production runs, consistent part numbers, traceability and logistic support for distributors.

Global Partnership

Pwm Fan Type

As your trusted supplier of PWM Fan solutions we provide services including specification support, custom branding, logistics coordination and after-sales support for large-scale buyers. Contact us to explore partnership.

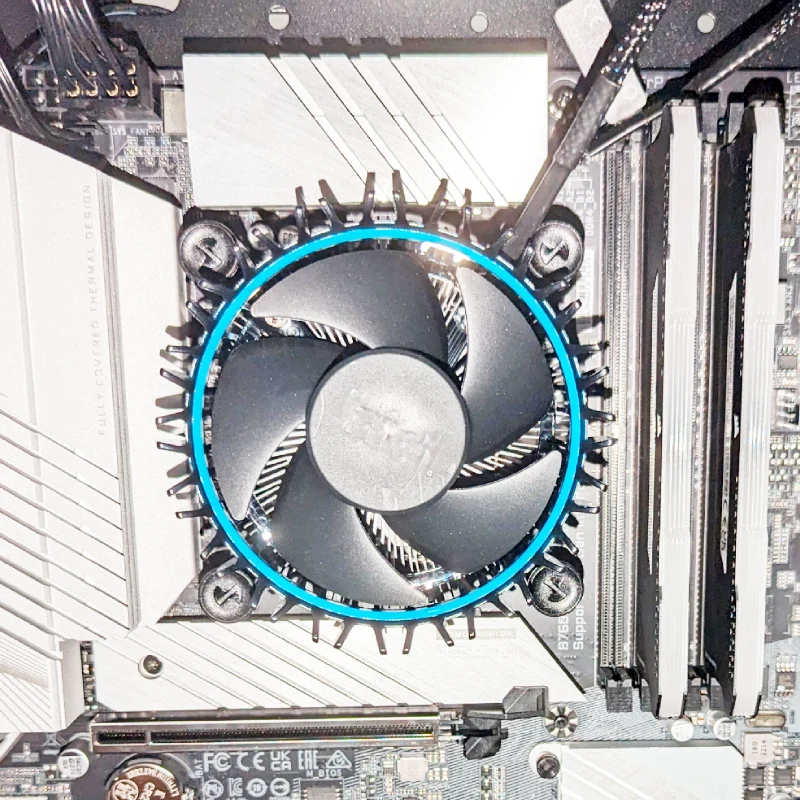

PWM Computer Fan

Description: A fan with built-in PWM control used in computer systems for cooling processors and components.

Key Features: 4-pin connector, duty-cycle speed control, low noise at low load.

Applications: Used by system integrators and wholesalers for computer chassis cooling, server racks and workstation builds.

PWM Case Fan

Description: An axial fan with PWM speed control designed for computer or control cabinet enclosure ventilation.

Key Features: Variable airflow, low RPM at idle, durability for long operation.

Applications: Ideal for PC case builds, control cabinets in industrial plants, telecom-signal enclosures.

PC Case Fan PWM

Description: A variant tailored for PC case environments offering PWM speed control, often bundled for bulk supply.

Key Features: Easy integration into PC builds, standard sizes (120mm, 140mm), low noise.

Applications: Wholesalers supply PC builders; system integrators for gaming rigs, workstation cases.

PWM Fan Controller Automotive

Description: A controller unit to manage PWM Fans in automotive or vehicular cooling systems (e.g., radiator, HVAC) with speed regulation.

Key Features: Automotive grade, supports 12 V or 24 V systems, integrates temperature sensors.

Applications: Automotive aftermarket distributors, industrial vehicle OEMs, machine cooling systems.

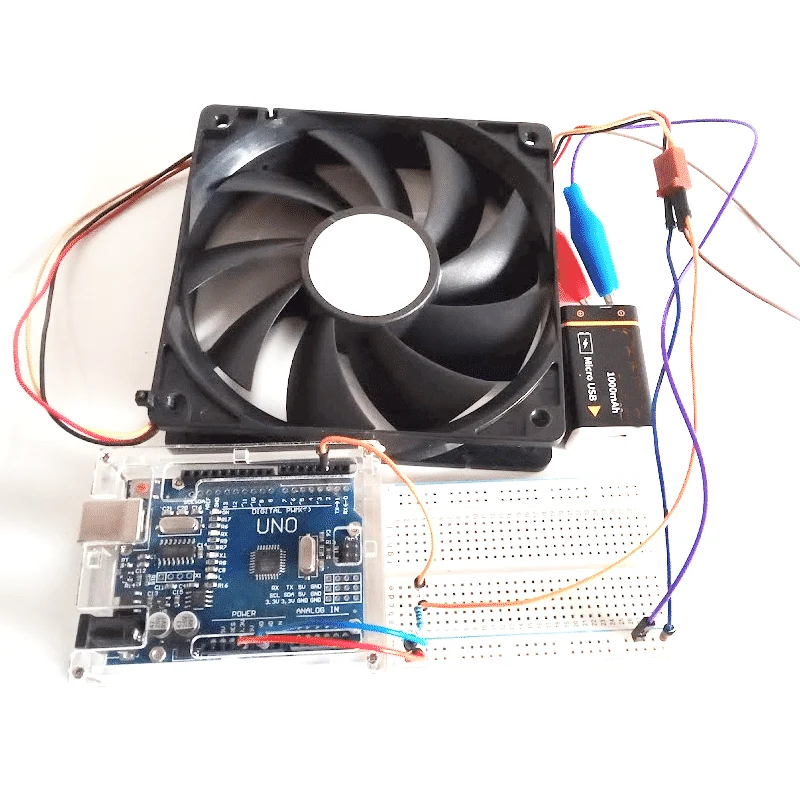

Cooling Fan PWM

Description: Generic category of cooling fans equipped with PWM control for industrial, computer and telecom use.

Key Features: Duty-cycle control, energy-efficient, noise-optimized.

Applications: Wholesalers supply panel-builders, system integrators, large-scale machine OEMs.

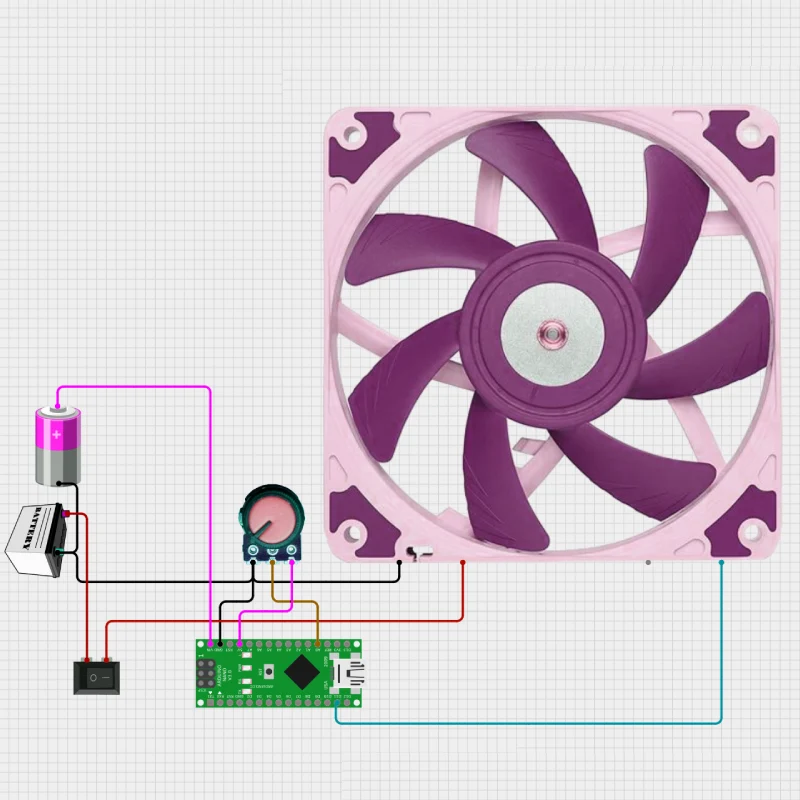

DIY PWM Fan Controller

Description: A module or kit designed for hobbyists or system integrators to build custom fan control using PWM for multi-fan systems.

Key Features: Programmable, supports multiple channels, ideal for small production or prototyping.

Applications: Product designers, small OEMs, custom machine builders, prototyping labs.

120mm PWM Fan

Description: A 120 mm size PWM Fan from Linkwellelectrics, optimized for high volume supply in both PC and industrial cabinet markets.

Key Features: Standard footprint, wide RPM range via PWM, scalable for brand bulk orders.

Applications: Used by control cabinet manufacturers, computer case producers, high-volume distributors. Contact us for custom branding.

140mm PWM Fan

Description: Larger 140 mm PWM Fan offering greater airflow at lower noise, suitable for bigger enclosures.

Key Features: Higher static pressure, slower RPM for quiet environments, compatible with standard mounts.

Applications: Industrial cabinets, larger telecom racks, PC cases needing high performance airflow.

200mm PWM Fan

Description: A large size PWM Fan designed for max airflow in industrial enclosures, telecom base stations and large computer cabinets.

Key Features: Massive airflow, PWM speed control, built for bulk-system integrators.

Applications: Electrical distribution cabinets, large control rooms, data-centre rack ventilation.

Pwm Fan Key Parts

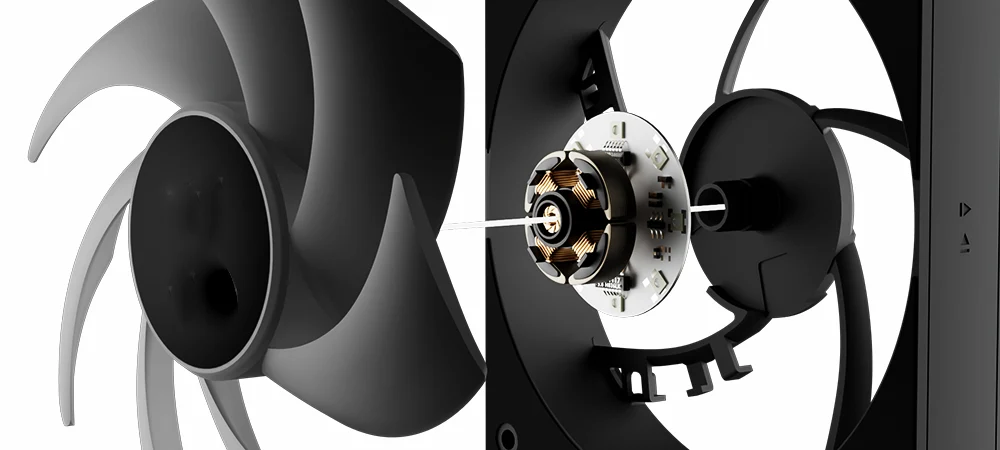

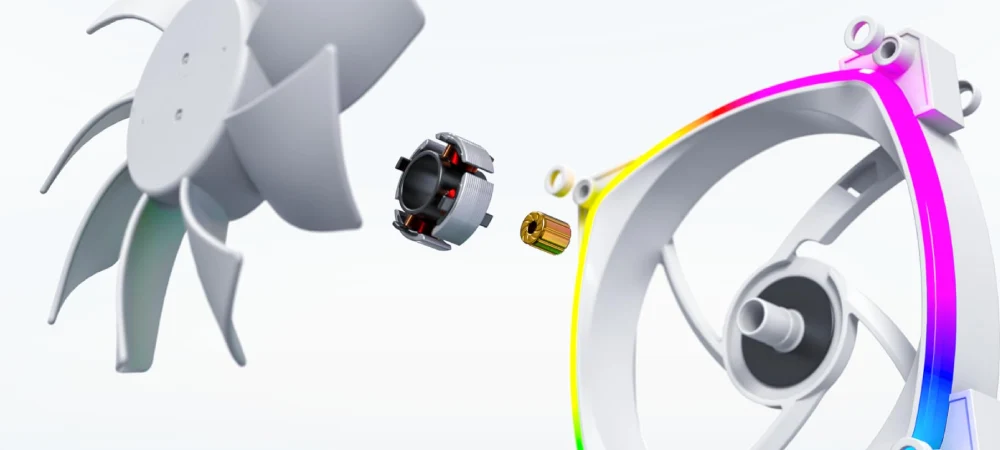

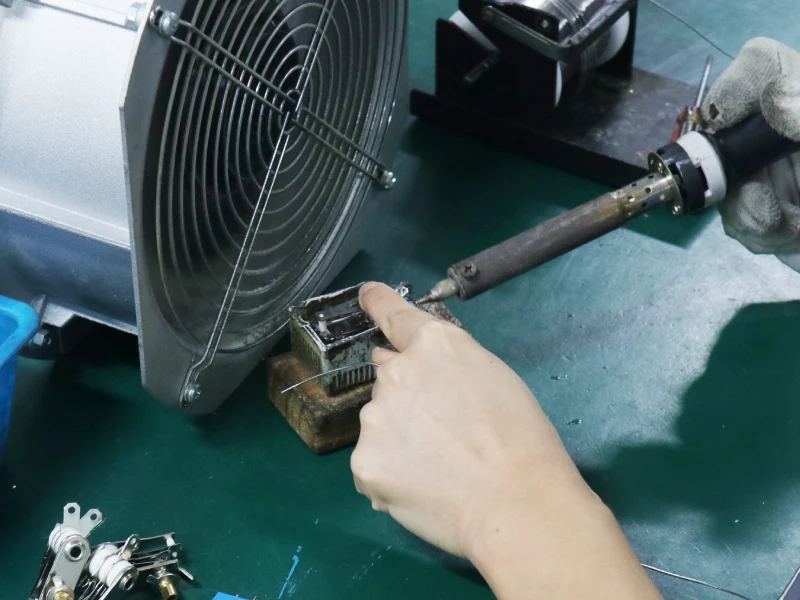

Motor & Bearing Assembly

This is the core of the fan. The motor drives the blades and the bearing determines longevity, noise and reliability in demanding conditions.

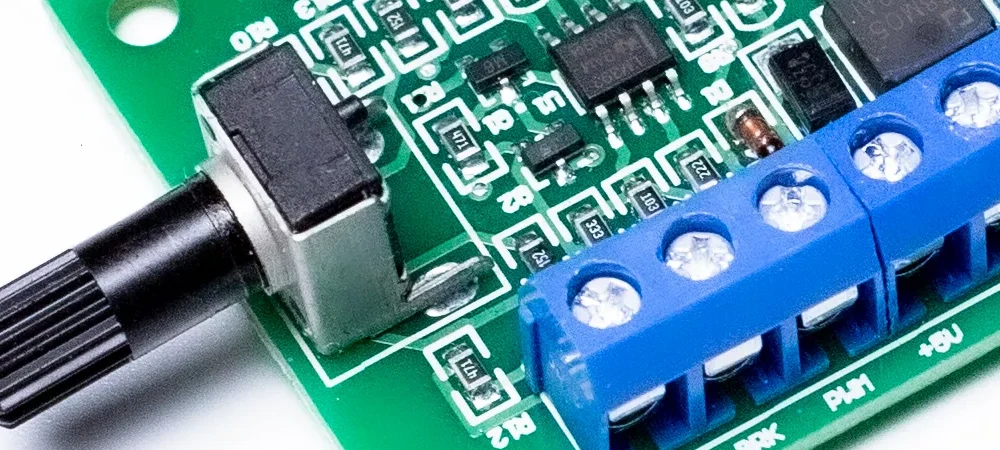

Electronics & PWM Control Board

This board interprets the PWM signal, gates the supply to the motor and regulates speed smoothly based on the duty cycle.

Blade & Frame Design

The blade geometry and frame impact airflow, static pressure and acoustics. In industrial or control-cabinet environments, the right design ensures better cooling, quieter operation and easier integration.

Certificate

Application of Pwm Fan in Different Industries

Industrial Automation

Telecom Base-Stations

Computer Manufacturing

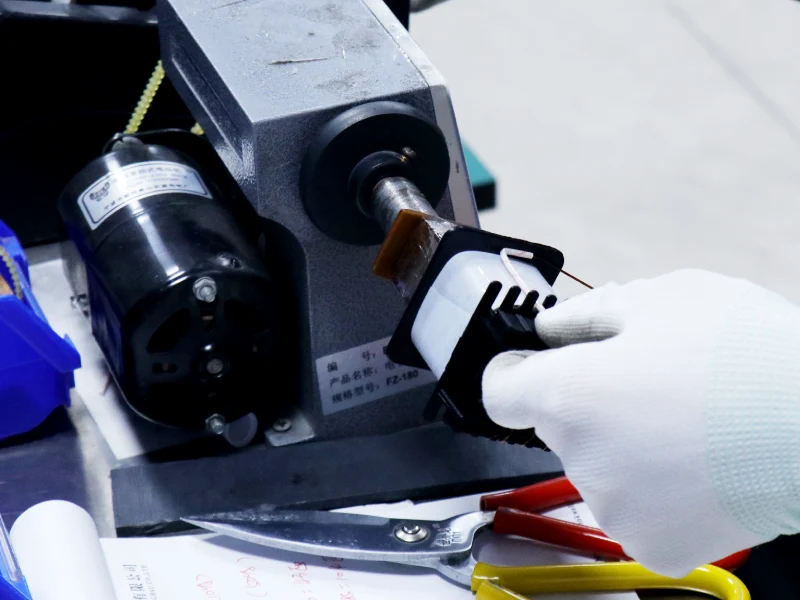

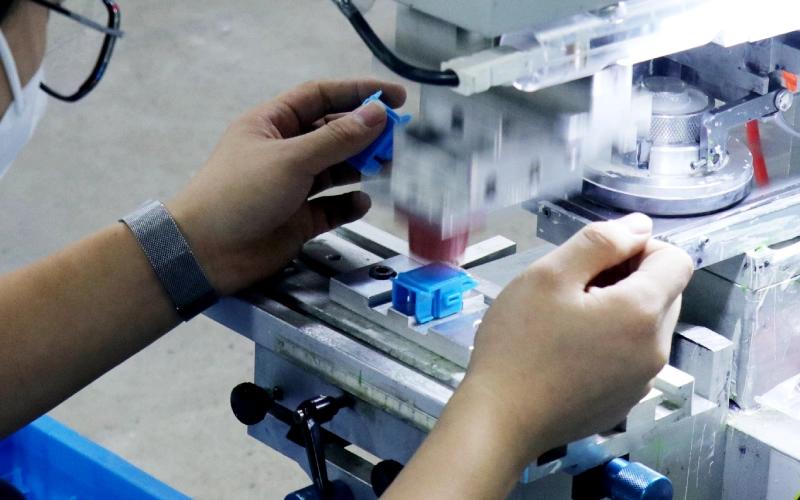

Our Factory

We provide full customisation of our PWM Fan – choose blade design, speed range, connector type, branding packaging and materials. This translates into lower cost per unit, consistent quality, faster turnaround and improved market competitiveness.

Customize Your Pwm Fan

Customisation & Branding

We allow blade geometry, connector type, label/branding, packaging design and speed profile customisation.

That flexibility differentiates your offering in the market rather than simply reselling commodity fans.

You can order with your brand name or ours, align with your client’s requirements and reduce re-packaging cost.

Technical Performance

Our PWM Fans use precision motors and 4-wire control enabling fine speed control based on demand.

Designed for industrial environments (control cabinets, telecom racks) with dust and vibration resistance.

Cost Efficiency

We optimise material and process so your unit cost stays competitive in bulk orders.

Larger batch volume reduces set-up cost per piece and improves margins for your distribution business.

Efficient logistics and consistent inventory mean you avoid emergency orders and excess stock.

Service & Delivery

We have rigorous quality control, track each production batch, and provide traceability for your buyers.

Our logistics system supports timely shipment and replenishment so you maintain uptime in your supply chain.

As a manufacturing partner focused on wholesale and brand-supply, we align with your business growth rather than one-off retail sales.

What is PWM Fan? How Does It Work? How Does It Work?

A PWM Fan (Pulse-Width Modulation fan) is a type of cooling fan whose speed is regulated by digital pulses rather than simple voltage changes. In modern electronics, control cabinets, computers and telecom equipment, managing fan speed is key to balancing airflow, noise and energy use.

What are the Benefits of Pwm Fan?

Improved energy efficiency: PWM Fans adjust speed to demand, reducing power use and lowering operational cost.

Noise reduction: By running slower when full airflow isn’t needed, PWM Fans reduce system noise — a big plus for control cabinets, telecom racks and computer builds.

Better performance & control: Precise speed regulation gives you flexibility in design (smaller fans, quieter systems), differentiates your offering and supports bulk-supply for large-scale installations.

Customer Testimonials

FAQ of Pwm Fan

What is a PWM Fan and where is it used?

A PWM Fan (Pulse-Width Modulation fan) uses a control signal to vary speed based on demand rather than running at fixed speed. It’s widely used in control cabinets, computer systems and telecom equipment to reduce noise, save energy and provide reliable cooling.

How does a PWM Fan differ from a DC fan?

A DC fan varies speed by changing voltage; a PWM Fan keeps voltage constant and uses a high-frequency signal to adjust duty cycle (i.e., how long the motor is powered) for better speed control, lower minimum speed and less noise.

Why is a 4-pin connector important for PWM Fans?

Most PWM Fans have four wires: ground, +12 V, tachometer (speed feedback) and the PWM control signal. That fourth wire is what enables the speed control, monitoring and integration into automated systems.

Can a PWM Fan be used in an electrical control cabinet environment?

Yes — if it meets the required industrial ratings (voltage, insulation, bearing type, thermal profile). Our models are designed for such use and we provide documentation to support cabinet builders and wholesale users.

What speeds and noise levels can I expect from a PWM Fan?

It depends on design: at lower duty cycles the fan can spin slowly for quiet operation; at high duty cycles it can ramp up for full airflow. The benefit is responsive cooling, less wasted energy and quieter systems when full speed isn’t required.

How often should the PWM Fan be inspected or replaced in industrial usage?

For commercial/industrial use we recommend periodic inspection of bearings, airflow drop and noise increase. Replacement intervals depend on environment, but tracking performance helps you maintain reliability for your end-clients.

Can Linkwellelectrics customise PWM Fans for my brand?

Yes — at Linkwellelectrics we manufacture customisable PWM Fans under our brand or yours. We offer custom blade design, connector type, branding, packaging and specific speed/airflow curves. Contact us to discuss your volume and specifications.

What is your minimum order quantity (MOQ) for custom PWM Fans?

Our MOQ is aligned with wholesale and OEM supply (typically hundreds to thousands per model). This suits distributors, panel-builders and system integrators rather than individual retail buyers.

All-in-one Pwm Fan Solutions for Your Project

Choosing us as your PWM Fan supplier delivers benefits on three key dimensions. First: Quality – our manufacturing lines adhere to strict standards, resulting in fans that perform reliably and reduce warranty risk. Second: Delivery – we maintain production and inventory capacity tailored to bulk orders, meeting your project timelines and avoiding supply gaps. Third: Market Insight – we understand the demands of electrical cabinet builders, computer system manufacturers and telecom integrators, helping you bring cost-effective, premium fan solutions to your clients. Let us be your manufacturing partner.