You want your terminal junction box wiring to be safe and reliable. Safety comes first, so you should never rush this process. Common mistakes like loose wire connections, missing grounding, or broken covers can create real hazards. Here’s a quick look at issues you need to watch for:

| Common Issue | Description |

|---|---|

| Loose Wire Connections | Can loosen over time, raising fire risk. |

| Corrosion and Moisture | Damaged insulation from humidity can cause safety risks. |

| Overcrowding of Wires | Too many wires can overheat and complicate repairs. |

| Lack of Grounding | Missing grounding increases electrocution risk. |

| Missing or Damaged Box Covers | Exposed wires break safety codes. |

Before you start, check your tools and materials. For peace of mind, trust Linkwell for high-quality terminal block connectors.

Key Takeaways

- Always turn off the power before working on a junction box. This simple step prevents electric shocks and keeps you safe.

- Use the right tools for wiring. Essential tools include wire strippers, screwdrivers, and a voltage tester to ensure a smooth process.

- Choose high-quality materials like Linkwell Terminal Block Connectors. They enhance safety and reliability in your electrical connections.

- Organize wires neatly inside the junction box. This prevents overcrowding and makes future maintenance easier.

- Double-check all connections before closing the junction box. A few extra moments can save you from serious problems later.

Junction Box Overview

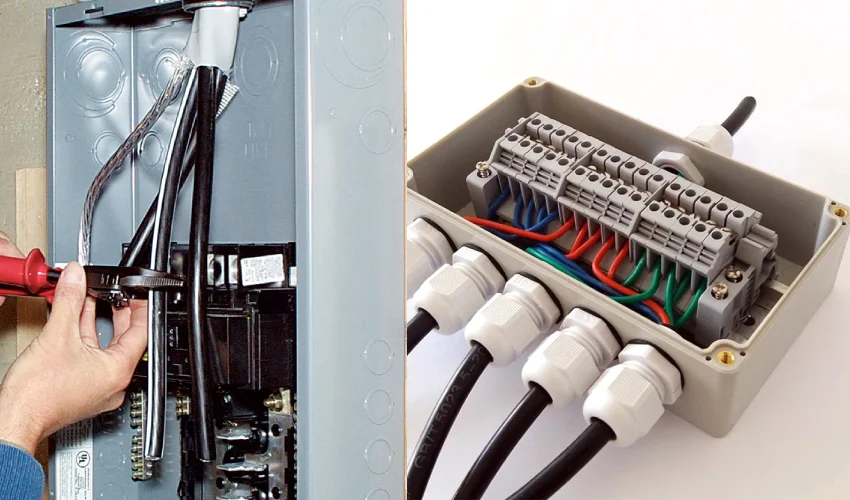

What Is a Junction Box

You might hear people call it a junction box, terminal box, or even a jbox. No matter the name, this small enclosure plays a big role in every electrical system. Take a look at this table to see how experts define a junction box:

| Term | Definition |

|---|---|

| Junction Box | A box through which the main conductors of a system of electric distribution pass, and where connection is made with branch circuits or to extend circuits. |

| Junction Box | An electrical junction box (also known as a “jbox”) is an enclosure housing electrical connections. Junction boxes protect the electrical connections from the weather, also playing a crucial role in protecting people from accidental electric shocks. |

You use a junction box or terminal box to keep all the wires in an electrical circuit safe and organized. It acts as a central hub where wires meet, split, or change direction. You find these boxes in homes, offices, factories, and anywhere you need to manage an electrical circuit. The terminal box shields wires from dust, moisture, and bumps. It also helps you follow electrical codes and keeps your electrical circuit safe.

Linkwell knows how important a reliable terminal box is. With years of experience, Linkwell creates high-quality cabinet components and terminal block connectors for all kinds of electrical systems. You can trust their products to keep your electrical circuit running smoothly.

Why Proper Wiring Matters

You might wonder why you need to pay attention to wiring inside a junction box or terminal box. Here’s why:

- The terminal box protects electrical connections from damage, moisture, and pests.

- It keeps your electrical circuit safe by reducing the risk of shorts, fires, and shocks.

- The box makes it easy to branch out wires to different devices or rooms.

If you wire a junction box or terminal box the right way, you lower the chance of electrical faults by up to 30%. The National Fire Protection Association reports about 51,000 home electrical fires every year in the U.S. Many of these start with poor wiring in a junction box or terminal box. The National Electrical Code even requires you to use a junction box in many situations.

When you choose Linkwell’s terminal block connectors, you get products that meet UL, CE, IEC, CCC, and ROHS standards. These certifications mean your electrical circuit and terminal box wiring will meet the highest safety and quality requirements.

Tip: Always double-check your connections in the terminal box before closing the cover. A few extra seconds can prevent big problems later.

Tools, Materials, and Linkwell Terminal Block Connector

Essential Tools for Wiring

You want your wiring job to go smoothly. The right tools make all the difference. Here’s what you should have on hand:

- Wire strippers for removing insulation without damaging the wire.

- Screwdrivers (flathead and Phillips) for tightening terminal screws.

- Needle-nose pliers for bending and positioning wires.

- Voltage tester to check if the power is off.

- Utility knife for trimming wires and insulation.

- Electrical tape for securing connections.

- Cable ties to keep wires neat and organized.

Tip: Always double-check your tool kit before you start. Missing tools can slow you down and lead to mistakes.

Materials Checklist

Choosing the right materials keeps your junction box safe and up to code. You need to match your materials to your environment and safety needs. Take a look at this table for a quick guide:

| Material Type | Description | Environmental Considerations |

|---|---|---|

| Metal | Stainless steel or aluminum, great for corrosive environments. | Low corrosion rate, prevents rusting and degradation. |

| Plastic | Used for general jobs, must be moisture-proof in damp places. | Check moisture-proof ratings for safety. |

| Non-combustible | Stainless steel and PVC help prevent fires. | Needed for fire safety and NEC compliance. |

You also need wire nuts, grounding screws, and, of course, a high-quality terminal block connector. Linkwell’s connectors fit perfectly with these materials and help you meet safety standards.

Linkwell Terminal Block Connector Features

Linkwell Terminal Block Connectors stand out for their safety and reliability. You get peace of mind knowing your connections are secure. Here’s what makes them special:

| Feature | Description |

|---|---|

| Voltage & Current Ratings | Handles up to 1000V and 30A–150A, perfect for demanding jobs. |

| Compliance Standards | Meets CE, RoHS, REACH, and IEC 61910 certifications for safety. |

| Material Quality | Tin-plated copper or brass gives you top conductivity and resists oxidation. |

| Operational Safety | Insulation barriers and arc-resistant housing keep accidents away. |

| Built-in Safety Toes | Stops terminal screws from loosening, so your connections stay tight. |

| Durable Materials | Designed to last, giving you long-term reliability. |

| Low Defect Rate | Quality control keeps defects well below international standards. |

| International Certifications | Multiple certifications show a strong focus on safety and reliability. |

You want a connector that’s easy to install and built to last. Linkwell delivers just that. You get a product trusted by professionals worldwide, so your wiring project stays safe and efficient.

Safety Precautions for Terminal Junction Box Wiring

Before you touch any wires in a junction box, you need to focus on safety precautions. You want to protect yourself and your electrical system. Linkwell always puts safety and quality first, so you can trust their products to help you follow the rules.

Power Shut-Off Procedures

You should always turn off the main power before you open a junction box. This step keeps you safe from electric shocks. Go to your electrical panel and flip the breaker for the circuit you plan to work on. Use a voltage tester to check that the wires inside the junction box have no power. Never skip this step. Even a small mistake can lead to serious injury.

Tip: Label the breaker you turned off. This helps you remember which circuit you are working on and keeps others from turning it back on by accident.

Personal Protective Equipment

You need the right gear to stay safe during electrical wiring. Here’s a quick table to show what you should wear and why:

| Personal Protective Equipment | Purpose |

|---|---|

| Insulated gloves | Protect against electric shocks |

| Safety glasses | Shield eyes from debris |

| Appropriate footwear | Prevent electric current from passing through the body |

| Hard hat | Protect from falling objects |

Don’t forget to check your equipment before you start. Good gear can make a big difference in electrical safety.

Common Mistakes to Avoid

Many people make the same mistakes when working inside a junction box. You can avoid trouble by watching out for these issues:

- Missing cable clamp: If you don’t secure the cable, the insulation can wear down and cause a fire. Always use a clamp to hold the cable in place.

- Using the wrong size conductors: Wires that are too small or too large can overheat or cause weak connections. Match the wire size to the other wires in the box.

- Wires that are too short or too long: Short wires make connections weak. Long wires create clutter. Measure carefully and leave 6-8 inches of slack.

- Loose connectors: Loose connections can overheat and start fires. Make sure connectors fit the wire size and type.

- Improper grounding: Always connect the main ground wire to the bus bar without breaks. Don’t daisy-chain grounds without proper connectors.

- Overloaded circuits: Too many devices on one circuit can trip breakers and overheat wires. Know your circuit’s rating.

- Incorrectly reconnecting wires: Take a picture or write notes before you disconnect anything. This helps you put everything back the right way.

Note: Following these safety precautions helps you avoid electrical hazards and keeps your wiring project on track. Linkwell’s terminal block connectors meet strict standards, so you get extra peace of mind.

Step by Step Terminal Junction Box Wiring Process

Wiring a terminal box can feel overwhelming, but you can break it down into clear steps. You want your terminal junction box wiring to be safe, neat, and up to code. Let’s walk through the process together.

Preparing the Junction Box

You need to start with a solid foundation. Here’s how you get your junction box ready for wiring:

- Secure the box. Mount the junction box to a framing member with at least two screws. This keeps it steady during installation and later maintenance.

- Run your cables. Guide the cables through the knockout holes. Use cable clamps to hold them in place. This step prevents strain on the wires and keeps your connections safe.

- Strip and prepare the wires. Remove the outer sheathing from the cables. Strip about 3/4 inch of insulation from the ends of each wire. Make sure you don’t nick the copper or aluminum.

- Double-check your box placement. The box should sit at the right height and location for easy access. You want it flush with the wall so the cover fits tight.

Tip: Always label your cables before you start making connections. This helps you keep track of each circuit inside the terminal box.

Securing and Connecting Wires

Now you’re ready to make the connections inside the terminal box. Follow these steps for safe and reliable wiring:

- Match wire types and gauges. Use only wires that meet the requirements for your electrical circuit. This keeps your installation safe and up to code.

- Group wires by function. Keep hot, neutral, and ground wires organized. Use wire nuts or terminal block connectors for secure connections.

- Twist wires together. For wire nuts, twist the wires clockwise before screwing on the connector. For terminal block connectors, insert each wire into the correct slot.

- Secure the ground wire. Attach the ground wire to the grounding screw or bus bar inside the junction box. Never skip this step.

- Neatly arrange the wires. Fold and tuck the wires into the box without overcrowding. This prevents stress on the connections and makes future troubleshooting easier.

Note: If you use Linkwell Terminal Block Connectors, you get a space-saving design that organizes wires efficiently and reduces installation errors.

Using Linkwell Terminal Block Connector

You want your connections to last. Linkwell Terminal Block Connectors make wiring easier and safer. Here’s how you use them for the best results:

- Select the right connector. Choose a terminal block connector that matches your wire gauge, current, and voltage needs. Linkwell offers a wide range of options for different projects.

- Insert the wire. Push the stripped end of the wire into the connector slot. Make sure the wire sits fully inside.

- Tighten the screw. Use a screwdriver to turn the screw clockwise until the wire is held firmly. Don’t overtighten, or you might damage the wire.

- Check the connection. Gently pull on the wire to make sure it’s secure. If you have a multimeter, test for a low-resistance path.

- Repeat for each wire. Keep your wires organized and avoid crossing them inside the terminal box.

Here’s a quick look at why professionals choose Linkwell Terminal Block Connectors:

| Benefit | Description |

|---|---|

| Wide Range of Options | Fits many installation needs and wiring types. |

| Quality Standards | Meets UL, CE, and IEC certifications for safe electrical connections. |

| Strong Materials | Uses polyamide and nylon for insulation and heat resistance. |

| Excellent Conductivity | Brass or copper bars, often tin-plated, prevent corrosion. |

| Reliable Connections | Zinc-plated steel screws hold wires tight and stable. |

Tip: Linkwell connectors help you save space, make maintenance easier, and boost safety by reducing the risk of electrical shocks or short circuits.

Final Inspection and Testing

You want to finish your terminal junction box wiring with a thorough check. Here’s how you make sure everything is perfect:

- Verify box placement and height. The junction box should match your plans and be easy to reach.

- Check wire type and gauge. Make sure all wires match the requirements for your electrical installation.

- Inspect all connections. Look for loose or faulty connections, overheating, burn marks, or corrosion. Every connection should be tight and clean.

- Confirm the box size. The junction box must have enough space for all wires and connections.

- Secure the cover. Attach the cover to protect the wires from dust and accidental contact.

Before you restore power, test your work:

- Use a voltage tester to check each wire and connection.

- Turn the breaker back on and test the circuit.

- Make sure all outlets, switches, and fixtures work as expected.

- If you find any problems, fix loose connections, repair damaged cables, and reassemble the box before restoring power.

Note: A neat, well-organized terminal box makes future maintenance and troubleshooting much easier. Always follow safety standards for every installation.

You’ve now completed your terminal junction box wiring. With careful preparation, secure connections, and reliable Linkwell Terminal Block Connectors, your electrical system will run safely and efficiently.

Conclusion

You’ve made it through every step of terminal junction box wiring. You know how to keep your work safe, neat, and up to code. Let’s recap the essentials so you can feel confident about your next electrical installation.

Here’s a quick table with the most important safety and compliance points:

| Category | Key Points |

|---|---|

| NEC Requirements | Junction boxes must be made from non-combustible materials and meet specific volume sizes. |

| Grounding Requirements | Must be grounded to prevent electrical shock hazards. |

| Accessibility | Must be installed in locations that are accessible for maintenance and inspection. |

| UL Listings and Certifications | UL-listed products ensure safety and compliance with relevant standards. |

| International Standards | Compliance with IEC and ISO standards ensures suitability for global applications. |

You want to follow a reliable process every time you wire a junction box. Here’s a checklist you can use:

- Turn off power at the breaker and confirm no voltage.

- Put on safety glasses and insulated gloves.

- Work in a dry area.

- Follow local codes.

- Prepare and secure the junction box.

- Strip wire ends.

- Connect ground wires with a wire nut.

- Twist and secure hot wires.

- Connect neutral wires.

- Fold wires into the box without overcrowding.

- Install the cover with screws.

- Restore power at the breaker.

- Test the circuit.

- Label the box for future reference.

If you ever feel unsure, reach out to a licensed electrician. Safety always comes first.

When you choose Linkwell Terminal Block Connectors, you get more than just parts. You get wiring efficiency, reliable operation at high current and voltage, and products that meet strict international standards. Take a look at what Linkwell’s website offers:

| Feature | Description |

|---|---|

| Wiring Efficiency | Simple and quick wiring with one input and multiple outputs. |

| Operational Reliability | Ensures normal operation at high current and voltage, supporting various cable branches. |

| Compliance | Meets UL94-V0, CE, UL, and ROHS certifications. |

You can explore more solutions and get expert support at Linkwell’s official website. Your next project will be safer and easier when you use trusted products and follow best practices.

You want every wiring job to be safe and reliable. Always follow each step and use the right safety gear. Quality products like Linkwell Terminal Block Connectors make your work easier and safer. If you ever feel unsure, ask a licensed electrician for help.

- Double-check your connections.

- Use trusted components.

- Stay up to date with safety codes.

FAQ

How do you choose the right terminal block connector for your project?

You should match the connector’s current and voltage rating to your circuit. Check wire size and insulation type. If you need help, visit Linkwell’s website for detailed specs and support.

Can you reuse Linkwell Terminal Block Connectors?

Yes, you can reuse them if they show no damage or wear. Always inspect the connector for cracks or loose screws before reinstalling. If you see any issues, replace it for safety.

What should you do if a wire comes loose inside the junction box?

Turn off the power first. Use a screwdriver to retighten the terminal screw. Double-check the connection by gently pulling the wire. If it feels secure, you can restore power and test the circuit.

Why do you need to label wires in a junction box?

Labeling wires helps you identify each circuit quickly. It makes future repairs or upgrades much easier. You avoid confusion and reduce mistakes during troubleshooting.