Water in your electrical panel spells trouble. Even a small leak can turn your fuse box into a safety hazard. You might see rust, flickering lights, or even smell something burning. Panels exposed to moisture risk short circuits and system failures. Preventing water damage saves you headaches and money. Linkewell designs panels and fuse box solutions that keep your electrical panel dry and reliable. Remember, Water in Electrical Panel Dangerous is not just a warning—it’s a real risk. Protect every fuse box and keep all panels safe.

Key Takeaways

- Water inside electrical panels creates serious safety risks like shocks, fires, and equipment failure.

- Seal all cable and conduit entry points tightly to stop water from entering your fuse box.

- Use waterproof enclosures with proper IP or NEMA ratings to protect panels from rain, dust, and floods.

- Elevate panels and ensure good drainage to prevent flood damage in vulnerable areas.

- Regularly inspect panels for moisture, rust, or damage and call a professional if you spot problems.

Water in Electrical Panel Dangerous

Risks and Hazards

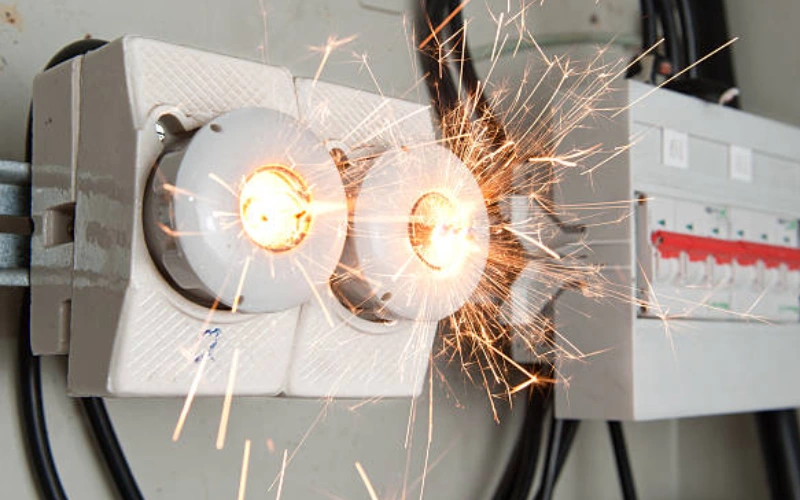

You might think a little water in your fuse box is no big deal, but water in electrical panel dangerous situations can happen fast. When water sneaks into your fuse box, it can turn safe metal parts into shock hazards. You could touch the panel and get a nasty surprise. The risk of electric shock jumps up, especially if you see rust or moisture inside the fuse box.

Here’s what can go wrong when water gets into your fuse box:

- Water conducts electricity, so even a small leak can energize the whole panel and make it unsafe to touch.

- Short circuits can spark fires. You might notice smoke or a burning smell coming from the fuse box.

- Corrosion eats away at metal parts, making the fuse box less reliable and more likely to fail.

- Floodwater or salty water brings in chemicals and debris, which can cause even more damage caused by water.

- Electrical parts like breakers, fuses, and switches can stop working right after water damage.

- Arc flashes can happen if water hits live parts. One worker washed down a panel and caused an arc flash that blew a hole in the box. That’s how water in electrical panel dangerous moments can turn into real emergencies.

If you ever spot water in your fuse box, don’t touch it. Let it dry out, and call a pro if you see smoke or hear buzzing. The risk of electric shock is just too high to ignore. Water-related emergencies can happen in seconds, so always stay alert.

Linkewell Panel Safety

You want your fuse box and panels to stay dry and safe. Linkewell designs panels with your safety in mind. Their electrical panel enclosures use IP-rated protection, from IP55 up to IP67, to keep out water and dust. These panels have sealed wiring paths and corrosion-resistant materials, so damage caused by water is much less likely.

Linkewell panels also include cabinet air conditioners, fan and filter units, and enclosure heaters. These features help prevent condensation and frost inside the fuse box. With IP65-rated ventilation systems and waterproof fans, your panels stay protected even in tough environments. You can trust Linkewell to help you avoid water damage and lower the risk of electric shock. When you choose Linkewell, you get electrical safety and peace of mind for every fuse box you own.

Prevention with Sealed Entry Points

Entry Points

You might not realize it, but every cable or conduit that enters your fuse box is a possible path for water ingress. Even a tiny gap can let moisture sneak inside, turning your electrical panel into a hazard. Water ingress often starts at these weak spots, especially if you have panels in basements, garages, or outdoor areas. If you want real prevention, you need to focus on sealing entry points right from the start.

Industry standards make this clear. For example, the NEC and DIN codes require that all cable and conduit entries in a fuse box must be watertight. Take a look at this quick table:

| Standard / Code | Requirement Summary |

|---|---|

| NEC 225.27, 230.8, 300.5 | Seal raceways and conduits to block water ingress |

| DIN 18322:2019-09 | Entries must be tightly sealed, both water and gas tight |

| Canadian Electrical Code | Conduit seals required in all conduit systems |

If you skip sealing entry points, you risk water ingress that can cause corrosion, short circuits, and even fires in your fuse box. Linkewell’s electrical panels and distribution boxes come with IP-rated enclosures, which means they’re built for watertight protection. These panels help you avoid the most common mistakes, like missing plugs or using the wrong materials.

Sealants and Gaskets

Choosing the right sealants and gaskets is key for prevention. Not all methods work the same. Some people use mastic putty or cement, but these can be messy or hard to re-enter. For your fuse box, you want solutions that last and keep water ingress out for good.

Here are some top methods for sealing:

- Grommet seals: Flexible and great for cables that move.

- Compression seals: Use pressure to create a watertight fit, perfect for industrial fuse box setups.

- Multi-cable entry seals: Let you run several cables through one opening while keeping each one sealed.

- Heat shrink seals: Shrink around cables to block water ingress.

Always pick sealants that match your environment. For example, if your fuse box faces chemicals or salt, choose a sealant that resists both. Non-hardening putty like Duct Seal works well for most panels. Specialized gaskets, like those used in Linkewell’s IP65/IP66 panels, give you watertight protection and make sealing entry points easy. Remember, prevention starts with the right materials and methods, so don’t cut corners when it comes to your fuse box.

Waterproof Enclosures for Water Damage

IP/NEMA Ratings

When you want to keep your fuse box safe from water damage, you need to know about IP and NEMA ratings. These ratings tell you how well your panels and custom flood panels can handle dust and water. IP ratings use two numbers. The first number shows how much dust can get in. The second number shows how much water the fuse box can handle. NEMA ratings are common in North America. They look at more than just water. They also check for things like corrosion and how strong the fuse box is.

Here’s a quick table to help you compare:

| IP Digit | Protection Against Solids or Liquids | Description |

|---|---|---|

| First Digit (Solids) | 0-6 | Ranges from no protection to total dust protection |

| Second Digit (Liquids) | 0-8 | Ranges from no protection to protection against long-term immersion under pressure |

NEMA ratings go further. For example, NEMA 4 and 4X keep your fuse box safe from rain, hose water, and even ice. NEMA 4X also stops corrosion, which is great for custom flood panels in tough places. If you need your fuse box to survive a flood, NEMA 6 and 6P are even better. They protect against submersion.

Tip: For most high-moisture areas, look for panels and custom flood panels with at least IP66 or NEMA 4X. This keeps your fuse box dry and working.

Linkewell Waterproof Solutions

You want your fuse box and panels to last, even when water tries to get in. Linkewell offers custom flood panels and enclosures with waterproof ratings like IP65, IP66, and IP67. These ratings mean your fuse box can handle dust, rain, and even strong water jets. Linkewell uses tough materials like stainless steel and high-grade plastic. These materials stop rust and keep your custom flood panels strong.

Linkewell’s fuse box designs use special gaskets and sealing systems. These features block water from sneaking in through cable holes or seams. You can even ask for custom flood panels with special hole designs or extra sealing for tricky spots. This makes your fuse box ready for outdoor use, food plants, or any place where water damage is a risk.

- Linkewell’s 5-way junction box has an IP66 rating, so it stands up to powerful water jets.

- You can pick custom flood panels with extra corrosion resistance for salty or chemical-heavy places.

- Every fuse box and panel is built for harsh weather, so you don’t have to worry about water damage shutting down your system.

If you want a fuse box that stays dry and safe, Linkewell’s custom flood panels give you peace of mind. You get protection, durability, and options that fit your needs.

Flood Prevention Methods

When you think about flood prevention methods for your electrical panels, you want to focus on two main strategies: elevation and drainage. These methods act as strong barriers against flood damage and help you follow flood protection guidelines for your facility.

Elevation

Elevating equipment is one of the most effective flood prevention methods you can use. By raising your electrical panels above the highest expected flood level, you create a physical barrier that keeps water away from sensitive components. You protect main service panels, disconnects, and even backup generators from direct contact with floodwaters. This step not only prevents flood damage but also makes it easier to restore power after a storm.

Many building codes and flood protection guidelines require elevation for electrical systems in flood-prone areas. If you move panels out of basements or low-lying spots and mount them higher on walls or upper floors, you reduce the risk of water intrusion. Elevation also helps you comply with regulations and ensures your system stays safe and reliable.

Tip: When elevating equipment, make sure to include all related wiring and backup power sources. This way, you create a complete barrier against rising water.

Drainage

Good drainage is another key part of flood prevention methods. You want to keep water from pooling near your panels. Start by grading the ground so water flows away from your building. Swales and French drains work well to channel water away from foundations and electrical equipment. If you have space, a retention pond can help manage heavy rainfall.

Always seal wire entry points and use waterproof electrical boxes to block water from sneaking in. Flood barriers, like raised curbs or shields, add another layer of protection. Remember, the best prevention comes from stopping water before it reaches your panels, not just dealing with it after the fact.

By combining elevation, drainage, and other barriers, you build a strong defense against flood damage. These flood prevention methods keep your electrical systems safe, reliable, and ready for anything.

Prevent Water Ingress with Regular Inspections

Regular inspections are your best friend when it comes to prevention. You can catch water ingress before it turns into a big problem. If you want to keep your electrical panels safe, you need to make inspections a habit. Most experts recommend a thorough inspection every two to three years. You should also do a quick visual check every few months. This routine helps you spot early signs of water ingress and keeps your system running smoothly.

Inspection Checklist

You don’t need to be an expert to spot trouble. Use this simple checklist during your electrical inspection:

- Look for any signs of water damage or moisture on the outside of the panel.

- Make sure all unused openings are sealed tight to prevent water ingress.

- Open the panel (if you’re trained) and check for moisture, rust, or corrosion inside.

- Inspect the enclosure for cracks, dents, or damage that could let water in.

Tip: If you see anything that looks off, like rust or water stains, call a professional right away. Prevention starts with quick action.

Signs of Water Damage

Spotting water ingress early can save you from headaches and costly repairs. Here are the most common signs you should watch for:

- Rust or corrosion on metal parts inside or outside the panel.

- Water droplets, condensation, or even a musty smell inside the enclosure.

- Discoloration, warping, or chalky-white buildup on screw terminals.

- Circuit breakers that trip often, blown fuses, or flickering lights.

- Burning smells, buzzing noises, or any unusual sounds from the panel.

If you notice any of these signs, don’t open the panel yourself. Water ingress can make things dangerous fast. Call a licensed electrician for a full electrical inspection. Prevention is all about catching problems early and keeping your electrical system safe.

Ventilation and Humidity Control

Condensation Prevention

You might not see it, but condensation is a sneaky enemy inside electrical panels. When warm, moist air meets a cooler surface, water droplets form. These droplets can drip onto wires and circuit boards, causing rust, short circuits, and even fires. If air inside your panel does not move, moisture builds up and settles on metal parts. That’s why you need good ventilation.

Tip: Keep the air moving inside your panel. Stagnant air lets moisture collect and turn into water droplets.

Here’s how you can prevent condensation in your electrical panels:

- Use vents or fans to keep air circulating. This helps push out humid air and bring in drier air.

- Install anti-condensation heaters. These small heaters keep the temperature above the dew point, so water can’t form.

- Try desiccants like silica gel. They soak up extra moisture, but remember to replace them regularly.

- Monitor humidity with indicator cards or electronic sensors. You’ll know right away if moisture levels get too high.

- Seal your enclosure well, but make sure it still allows for some airflow.

If you live in a humid area, keep the relative humidity inside your panel below 60%. Use heaters with hygrostats or hygrotherms. These devices turn on the heater only when humidity rises, saving energy and keeping your panel dry.

Linkewell Ventilation Systems

You want a solution that works, right? Linkewell offers a full lineup of ventilation systems designed to fight moisture and keep your electrical panels safe.

- Fan Filter Units (FFUs): These combine powerful fans with filters to move air and block dust and moisture. Great for factories and busy workspaces.

- Cabinet Air Conditioners: These sealed units cool your panel and filter out dust and water. They work well in hot or outdoor spots.

- Electrical Cabinet Louvers: These vents let air flow in and out but keep rain and debris out. They’re perfect for mild climates.

- Enclosure Thermostats and Heaters: These smart devices control temperature and humidity. They turn on fans or heaters when needed to stop condensation.

Linkewell’s cabinet air conditioners use inverter compressors and EC fans for smart, energy-saving cooling. Their enclosure heaters keep things warm enough to stop condensation, even in cold weather. With these systems, you get peace of mind knowing your panels stay dry, safe, and reliable—no matter the climate.

Professional Installation and Maintenance

Expert Support

Getting your electrical panel installed by a professional makes a huge difference. You want your system to last, stay safe, and keep water out. Licensed electricians know how to do the job right. They follow local building codes and use weatherproof enclosures with the right NEMA ratings, like NEMA 3R or higher. This keeps moisture from sneaking in.

Here’s what you get when you choose expert installation:

- Compliance with all local codes and safety standards.

- Weatherproof enclosures that block rain and splashes.

- Careful sealing around every wiring entry point.

- Panels elevated above ground to avoid water exposure.

- Use of corrosion-resistant materials and strong sealants.

- Extra features like locking doors for added safety.

Tip: Always ask about your installer’s certifications. Certified electricians have special training in waterproofing, panel assembly, and safety. They know how to organize wires, use the right materials, and test everything before finishing the job.

Check out some common certifications for electricians:

| Certification Name | Provider/Issuer | Description Summary |

|---|---|---|

| General Electrician Certification | State Licensing Boards | Validates skills in installation, safety, and code compliance. |

| Master Electrician Certificate | State Licensing Boards | Shows advanced expertise in design, installation, and safety. |

| Certified Electrical Safety Compliance Professional (CESCP) | NFPA | Focuses on electrical safety and NFPA 70E standards. |

| Journeyman Electrician License | NECA | Demonstrates practical installation skills and code knowledge. |

Linkewell Service

You don’t have to handle maintenance alone. Linkewell offers support every step of the way. Their team helps you choose the right panel, install it, and keep it running smoothly. You get advice on sealing, waterproofing, and regular checks.

Here’s how you can keep your panels safe from water damage:

- Inspect your panel for moisture or corrosion every few months.

- Seal gaps and use waterproof sealants where needed.

- Keep the area around your panel dry—fix leaks, seal cracks, and use sump pumps if needed.

- Install surge protectors to guard against power spikes.

- If you spot water, turn off the power and call a pro.

Linkewell’s experts can guide you through these steps. They offer 24/7 support, fast delivery, and custom solutions for your needs. With Linkewell, you get peace of mind knowing your electrical system is protected and maintained by professionals who care.

Taking steps to prevent water damage in your electrical panels keeps your building safe and saves you money. When you use smart strategies and Linkewell’s reliable products, you avoid costly repairs, reduce fire risks, and help the environment.

- You stop corrosion and rust before they cause big problems.

- You lower the chance of electrical fires and equipment failure.

- You cut down on wasted resources and pollution from damaged systems.

Stay proactive—use these tips or reach out to Linkewell for custom solutions and ongoing support. Your safety and savings start with prevention.

FAQ

What should you do if you find water inside your electrical panel?

Turn off the main power if it’s safe. Don’t touch anything wet. Call a licensed electrician right away. Water and electricity together can be very dangerous. Stay safe and let a pro handle it.

How often should you inspect your electrical panels for water damage?

Check your panels every six months. Look for rust, moisture, or odd smells. Quick visual checks every few months help catch problems early. Regular inspections keep your system safe and reliable.

Can you use any sealant to waterproof entry points?

No, you need the right sealant for your environment. Use non-hardening putty, silicone, or gaskets rated for electrical use. Some sealants work better in wet or chemical-heavy areas. Always follow manufacturer recommendations.

Are Linkewell panels suitable for outdoor installations?

Yes! Linkewell panels come with IP65, IP66, or IP67 ratings. These enclosures keep out rain, dust, and even strong water jets. You can trust them for outdoor or harsh environments.

Why is ventilation important in electrical panels?

Ventilation stops condensation from forming inside your panel. Good airflow keeps moisture away from wires and circuits. This helps prevent rust, short circuits, and system failures. Reliable panels need dry, well-ventilated spaces.

Conclusion

Water in electrical panel dangerous situations are more than just warnings—they’re real threats to safety and system reliability. Even a small leak can cause short circuits, fires, and equipment failure. With proper sealing, ventilation, waterproof enclosures, and regular inspections, you can prevent costly damage. Linkewell offers trusted solutions to keep your panels dry and secure, ensuring peace of mind for both indoor and outdoor electrical installations.