You know how vital it is to keep your electrical systems running smoothly. When you ignore electrical enclosure thermal management, you risk more than just minor hiccups. Take a look at what temperature extremes and moisture can do:

| Risk Type | Description |

|---|---|

| Excessive Heat | Can cause components to overheat, leading to reduced lifespan and malfunctions. |

| Extreme Cold | Makes plastics brittle and increases the risk of condensation inside enclosures. |

| High Humidity | Creates condensation, leading to corrosion, ionic conduction, and electrical shorts. |

| Sudden Temperature Change | Can cause moisture accumulation similar to high humidity, affecting component reliability. |

If you want true protection and reliable performance, you need both enclosure heating and effective cooling. Linkwell’s solutions help you avoid corrosion, electrical shorts, and costly downtime. With smart thermal management, your equipment stays efficient year-round.

Key Takeaways

- Control temperature to prevent overheating. This extends the life of your electronic components and reduces the risk of malfunctions.

- Use enclosure heating to stop condensation. Keeping the internal temperature above the dew point prevents moisture-related issues like corrosion and shorts.

- Implement effective cooling systems to remove excess heat. This helps maintain optimal operating conditions and minimizes downtime.

- Regular maintenance of heating and cooling systems is crucial. Schedule inspections and clean filters to ensure reliable performance and longevity.

- Choose the right heating and cooling solutions based on your environment. Assess temperature swings and humidity levels to determine your needs.

Risks and Challenges

Condensation and Moisture

You might not notice condensation right away, but it can sneak up on you inside an electrical enclosure. When warm air meets a cold surface, water droplets form. This moisture can cause a lot of trouble:

- Corrosion starts to eat away at metal parts.

- Mold can grow, making the enclosure unsafe and dirty.

- Water can pool at the bottom, leading to drainage problems.

- Short circuits may happen when water touches live parts.

- Sensitive electronics, like PLCs and VFDs, can break down early.

- Frost can form in cold conditions, causing malfunctions.

- Workers face a shock hazard if they touch wet components.

Condensation in electrical enclosures often leads to immediate electrical failures. Moisture on conductors and terminals can cause short circuits. Over time, you see corrosion build up, which increases resistance and can cause system failures. If you want real protection, you need to control both temperature and humidity. Enclosure heating helps keep the inside of your cabinet above the dew point, stopping condensation before it starts.

Overheating and Downtime

Heat is another big enemy inside your enclosure. When temperatures rise, your equipment suffers. Here’s what happens:

- Every 10°C increase in temperature cuts the life of electronic components in half.

- Heat stress is a top reason for early equipment failure.

- Most electrical gear works best below 40°-50°C (104°-122°F). Go above that, and you risk big problems.

- Overheating can cause random shutdowns, sensor errors, and PLC faults.

Tip: If you want to prevent malfunction due to overheating, you need a good cooling system. Electrical enclosure ventilation and cooling fans help remove dangerous heat, keeping your electronics safe.

Downtime from overheating can get expensive fast. Lost revenue piles up when production stops. Delays hurt your reputation and make customers unhappy. Some factories lose hundreds of thousands of dollars per hour during downtime. That’s why temperature-related interruptions are a huge concern for anyone managing industrial systems.

Impact on Uptime

You want to keep your systems running as much as possible. That’s what maximizing uptime is all about. Poor thermal management leads to more downtime, which means more interruptions and higher costs. Here’s how it affects your operation:

- Cooling systems remove heat and prevent overheating of sensitive electronics.

- Keeping the right temperature reduces condensation and corrosion risks.

- Less downtime means fewer repairs and lower maintenance costs.

- You get more reliable performance and longer equipment life.

Check out this table to see how temperature affects the lifespan of common components:

| Component | Nominal Temp. Rating | Lifespan Reduction at +10°C | Lifespan Reduction at +20°C |

|---|---|---|---|

| PLC/Controller | 25°C (77°F) | 50% | 75% |

| Variable Frequency Drive | 40°C (104°F) | 50% | 75% |

| Power Supply | 40°C (104°F) | 50% | 75% |

| Capacitor | 25°C (77°F) | 50% | 75% |

When you focus on both enclosure heating and cooling, you’re reducing interruptions and keeping your equipment running longer. That’s the key to reliable electrical enclosure thermal management and better uptime.

Enclosure Heating Solutions

Linkwell Enclosure Heaters

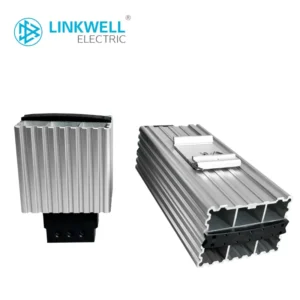

When you want real protection for your electrical enclosures, you need a heating solution you can trust. Linkwell enclosure heaters give you that peace of mind. These heaters are designed for tough industrial environments, from control cabinets to telecom racks. You get a product that stands up to dust, water, and harsh weather. The robust aluminum housing resists corrosion, and the IP65 full-seal design keeps out moisture and dirt.

You care about safety and compliance. Linkwell enclosure heaters come with top certifications, so you know you’re getting reliable and safe equipment. Here’s a quick look at the certifications you’ll find on these heaters:

| Certification | Description |

|---|---|

| CE | Conformité Européenne, indicating compliance with EU safety standards. |

| RoHS | Restriction of Hazardous Substances, ensuring limited use of specific hazardous materials. |

| UL | Underwriters Laboratories, a safety certification for electrical devices. |

| ATEX | Equipment safety certification for use in explosive atmospheres. |

You can choose from a wide range of power ratings, from 10W to 500W, and select the mounting style that fits your setup. Linkwell enclosure heaters also offer built-in or external thermostats, hygrostats, and digital controllers for precise temperature control. You get a solution that adapts to your needs, whether you’re working in a freezing substation or a humid factory.

Moisture and Temperature Control

Moisture is the silent enemy inside your electrical enclosures. You might not see it, but it can cause big problems. Linkwell enclosure heaters tackle this head-on. They keep the internal temperature at least 9°F (5°C) above the ambient air. This small difference makes a huge impact. It stops condensation from forming on your sensitive electronics.

Here’s what happens when you use enclosure heaters for moisture protection:

- You avoid short circuits caused by water’s conductive properties.

- You stop premature oxidation of electrical contacts.

- You prevent corrosion of metallic parts, which keeps your system safe and strong.

- You reduce the risk of mold and frost inside your enclosure.

- You keep your equipment running, even when the weather outside changes fast.

Enclosure heaters do more than just keep things warm. They promote internal air circulation and heating, which helps prevent freezing and keeps humidity in check. Even in mild weather, enclosure heaters protect against condensation and humidity spikes. This is key for maximizing uptime and keeping your thermal management system working at its best.

A recent study on climate control in museums shows how important heating is for stable temperature and humidity. Heating systems help maintain a stable environment, which is crucial for protecting equipment and extending component life. Good airflow and balanced humidity-heat levels mean your electronics stay safe and your enclosure stays dry.

Energy Efficiency

You want to keep your costs down while protecting equipment. Linkwell enclosure heaters make that possible. Each heater uses a precise thermostat, so it only runs when needed. This smart temperature control saves energy and reduces wear on your system.

Let’s see how energy-efficient heating helps your bottom line:

| Evidence Description | Impact on Operational Costs |

|---|---|

| Reduces strain on cooling systems | Lowers energy consumption and maintenance expenses |

| Decreases need for excessive active cooling | Cuts energy bills and maintenance costs |

| Maintains stable internal temperatures | Protects components, leading to longer service life and fewer downtimes |

When you use enclosure heaters with smart controls, you get stable temperature inside your cabinets. This means less stress on your cooling fans and air conditioners. You spend less on repairs and replacements. You also avoid sudden shutdowns and keep your operations running smoothly.

Tip: Preventive heating is not just about warmth. It’s about preventing condensation, protecting equipment, and ensuring reliable performance. When you combine heating with cooling, you create a complete electrical enclosure thermal management plan that keeps your systems safe all year.

You want to extend component life and keep your business moving. Linkwell enclosure heaters give you the moisture protection, stable temperature, and energy savings you need. That’s how you stay ahead in today’s demanding industrial world.

Ventilation and Cooling

Linkwell Electrical Enclosure Ventilation

You want your electrical enclosures to stay cool and safe, no matter how tough the environment gets. Linkwell offers a full lineup of enclosure cooling solutions to help you do just that. You can pick from fan filter units, cabinet air conditioners, electrical cabinet louvers, and enclosure thermostats. Each one fits a different need, so you always have the right tool for the job.

| Ventilation Solution | Main Applications |

|---|---|

| Fan Filter Units | Factories, automation panels, CNC machines—great for dusty or industrial spaces |

| Cabinet Air Conditioners | Telecom, automation, power control—perfect for high-heat or outdoor environments |

| Electrical Cabinet Louvers | Control rooms, outdoor cabinets—ideal for passive airflow |

| Enclosure Thermostats | Control panels, automation, outdoor boxes—keeps temperatures in check |

You get enclosure cooling that works for any setup, from small control panels to large industrial cabinet cooling systems.

Recommended products

Temperature Regulation

Keeping the right temperature inside your enclosure is key. If you let things get too hot, you risk equipment failure and downtime. Linkwell’s enclosure cooling products help you remove excessive heat and keep your electronics safe. Here’s how these systems work:

- Fans and blowers pull in cool air and push out hot air.

- Air-to-air heat exchangers move heat outside without mixing air streams.

- Cabinet air conditioners use refrigerants to keep things stable.

Proper enclosure cooling keeps your internal temperature below the danger zone. Most electrical enclosure equipment works best below 40°C (104°F), but some enclosures can handle up to 80°C. Check out this chart to see the temperature ranges for different enclosure types:

When you use enclosure cooling, you avoid thermal stress, condensation, and corrosion. You also extend the life of your equipment and lower your maintenance costs.

System Reliability

You want your systems to run without interruption. That’s where enclosure cooling really shines. Linkwell’s enclosure cooling fans and air conditioners come with CE certification, so you know they meet strict safety standards. The fans use ball bearings and brushless motors, which means they last longer and need less maintenance. Some models run up to 75,000 hours—perfect for industrial cabinet cooling that never stops.

Linkwell’s enclosure cooling solutions use smart controls and energy-efficient fans. This helps you cut operational costs and keep your equipment safe. When you combine enclosure heating with effective cooling, you get the best electrical enclosure thermal management. You protect your investment, maximize uptime, and keep your business running smoothly.

Best Practices

Selection and Sizing

Choosing the right heater or ventilation system for your enclosure can feel tricky, but you can make it easier by focusing on a few key factors. Here’s a quick table to help you compare what matters most:

| Factor | Description |

|---|---|

| Compliance Standards | Make sure your system meets OSHA, local energy codes, and industry standards. |

| Operating Temperature | Know the temperature range your equipment needs to stay safe. |

| Ambient Conditions | Think about airflow, enclosure design, and nearby heat sources. |

| Space Constraints | Check if you have enough room for the heater or fan you want to install. |

You want to avoid common mistakes, so remember these points:

- Don’t treat cooling as an afterthought—plan for it early.

- Always check the ambient temperature where you’ll install the enclosure.

- Watch out for extra heat from sunlight or nearby machines.

- Lay out your equipment to prevent hot spots.

- Make sure air can flow freely.

- Calculate the heat load carefully so you don’t undersize your system.

Installation and Maintenance

You can get the most out of your enclosure heating and cooling systems by following a few simple steps:

- Schedule regular professional maintenance to catch problems early.

- Change air filters often to keep airflow strong and clean.

- Keep outdoor units clear of debris.

- Clean vents and ducts so air moves easily.

- Inspect seals and gaskets to stop leaks and moisture.

- Set up a cleaning schedule and stick to it.

Tip: Regular inspections help you spot rust, water damage, or airflow issues before they cause downtime. Good maintenance means longer equipment life and better uptime.

Custom Solutions

Every project is different. Sometimes you need more than a standard product. Linkwell can help by looking at your unique needs, picking the right heating and cooling systems, and making sure everything fits your space and heat load. The team can customize solutions for tough environments, whether you face extreme cold, high humidity, or blazing heat.

Here are some real-world results:

| Case Study Description | Outcome |

|---|---|

| Wall-mounted enclosure at a coastal transit depot | Zero water ingress after 6 years |

| Thermally bonded panels in racks | Internal temps dropped by 15°C, boosting component life by 25% |

| EV toll-road operator | No shutdowns during 47°C heatwaves |

| Maintenance teams | Zero faults at –40°C; fans never iced over |

When you work with Linkwell, you get support from start to finish. That’s how you keep maximizing uptime and get the most from your electrical enclosure thermal management plan.

You now see why both heating and cooling matter for electrical enclosure thermal management. Here’s what you need to remember:

- Control temperature to prevent overheating and extend component life.

- Keep out dirt, water, and corrosive vapors.

- Remove excess heat and avoid malfunctions with proper enclosure heating and cooling.

Linkwell’s solutions boost uptime and reliability with high protection ratings, modular designs, and advanced safety features.

| Contact Method | Details |

|---|---|

| Phone | +86-15599094304 |

| linkwell@linkwellcn.com | |

| Social Media | Linkedin, Facebook, Youtube |

Take a moment to assess your needs. Reach out to Linkwell for expert help and keep your systems running strong.

FAQ

What happens if I skip heating or cooling in my electrical enclosure?

You risk condensation, overheating, or both. Moisture can cause corrosion and shorts. Excess heat can damage electronics. You need both heating and cooling to keep your equipment safe and reliable.

How do I know if my enclosure needs a heater, a cooler, or both?

Check your environment. If you see temperature swings, high humidity, or outdoor exposure, you likely need both. Use a heater to stop condensation and a cooling fan or AC to prevent overheating.

Can I install both a heater and a cooling fan in the same enclosure?

Yes, you can. Many enclosures use both. Heaters keep things dry and above the dew point. Cooling fans or air conditioners remove excess heat. This combo gives you full thermal protection.

How often should I maintain my heating and cooling systems?

Inspect your systems monthly. Clean filters and vents. Check for dust, rust, or water. Replace filters every 3–6 months. Regular maintenance keeps your enclosure running smoothly and extends equipment life.

Will using both heating and cooling increase my energy bills a lot?

Not if you use smart controls. Thermostats and hygrostats run heaters and coolers only when needed. This saves energy and keeps costs low. You get protection without wasting power.