You will see new problems in electrical enclosure design in 2025 because safety and rules are getting tougher.

- You need to pick materials that follow OSHA, NEMA, and UL rules so the enclosure can block dust, water, and shaking.

- Smart features help you work better, like AI temperature control and tools that warn you before things break, so you have less downtime.

- When you design electronic enclosures, you should plan for easy upgrades and ways to connect with Industry 4.0.

- Good airflow is still very important to stop things from getting too hot and to make them last longer.

- People now want enclosures that they can change, that are smart, and that are good for the environment.

Linkwell is a great partner because they make new electronic enclosure designs and strong ventilation systems that help you follow world rules.

Electrical Enclosure Design Key Takeaways

- Pick materials and designs that follow safety rules like OSHA, NEMA, and UL. These help keep equipment safe from dust, water, and harm.

- Make your enclosure bigger by at least 20% for airflow and upgrades. This helps you save time and money in the future.

- Use good ways to cool things down, like fans or air conditioners. This stops things from getting too hot and helps equipment last longer.

- Get enclosures with high IP or NEMA ratings to block water and dust. This is very important for outdoor places or tough conditions.

- Keep wires neat and label everything so it is easy to fix. This makes maintenance simple and cuts down on lost time.

Electrical Enclosure Design Fundamentals

Purpose & Benefits

When you begin electrical enclosure design, you make things safer and easier. You keep your team and equipment safe by using the right rules. Here are the main reasons why enclosure design is important in every industry:

- Equipment Protection: You keep electronics safe from dust, water, heat, and bumps. Stainless steel enclosures in food plants protect control panels from washdowns and rust.

- Enhanced Electrical Safety: You stop people from touching live parts by mistake. This lowers the chance of shocks, fires, and tampering. NEMA 1 enclosures in offices keep indoor wiring safe.

- Organization and Maintenance Efficiency: You make wires and devices neat and tidy. This helps you fix problems faster and saves money on repairs. Modular enclosures in factories help teams find problems quickly.

- Compliance with Industry Standards: You follow safety rules by using certified enclosures. Utility companies use NEMA 4X enclosures outside to meet OSHA and NEC rules.

Tip: Good electrical enclosure design helps you avoid expensive downtime and keeps your systems working well.

Key Industry Standards

You must follow strict standards when you design enclosures. These rules help you pick materials, plan layouts, and set protection levels. The table below lists the most important standards for electrical enclosure design in 2025:

| Standard/Rating | Governing Body | Description | Role in Electrical Enclosure Design |

|---|---|---|---|

| IEC 62208 | IEC | Requirements for empty enclosures | Sets global design guidelines |

| IP Ratings | IEC | Protection against dust and water | Measures enclosure protection |

| NEMA 250 | NEMA | U.S. protection levels | U.S. design guidelines |

| UL 94 | UL | Flame resistance of materials | Ensures fire safety compliance |

You should always check these standards before picking materials or planning your enclosure. By following these rules, you make sure your enclosures are safe, strong, and ready for any place.

Material Selection

Durability & Certifications

Picking the right material helps your enclosure last a long time. Each material works best in certain places and for different jobs. Here are some common materials and why people use them:

- Plastics are good at stopping shocks and do not rust. They cost less and you can change their shape or color for safety or looks.

- Stainless steel is strong, does not burn easily, and works well in wet places. You see it a lot in food factories or outside.

- Carbon steel is strong and not expensive, but it needs a coating to stop rust, especially near the ocean.

- Aluminum is light and does not rust. It also blocks EMI and RFI, which helps protect electronics.

- Polycarbonate plastic is very tough and can be used inside or outside.

- ABS plastic is cheap and can take hits and heat, so it is good for inside use.

| Material | Advantages |

|---|---|

| Mild Steel | Cheap and works well where you do not need much strength |

| Stainless Steel | Does not rust, is strong, and is good for tough or wet places |

| Galvanized Steel | Lasts a long time and does not rust because of its zinc layer |

| Aluminum | Light, does not rust, and is good for telecom and planes |

| Polycarbonate Plastic | Cheap, very strong, does not rust, and works inside or outside |

| ABS Plastic | Cheap, takes hits and heat, and is good for inside use |

| Powder Coating | Makes metal enclosures stronger, stops rust, and looks nice |

If you pick materials with UL, NEMA, or CE certifications, your enclosure will be safe and work well. UL certification means the enclosure passed hard tests for fire, strength, and weather. This helps stop fires, electrical problems, or things breaking. Certified enclosures keep your equipment safe and working, even in hard places.

Tip: Always look for UL 50 or UL 50E certifications. These show the enclosure can handle water, dust, hits, and big temperature changes.

Corrosion Resistance

Corrosion can make your enclosure stop working and not last as long. You should plan for corrosion resistance from the start. Here are some ways to protect your enclosure:

- Check if there are chemicals, salt, water, or very hot or cold weather.

- Pick materials that do not rust, like stainless steel, polycarbonate, or fiberglass-reinforced polyester.

- Make sure your enclosure has NEMA 4X, UL, or IP ratings.

- Design with sealed edges and finishes that block water and dust.

- Use stainless steel hinges and latches to make it last longer.

- Pick silicone gaskets to keep out water and chemicals.

- Cover cooling parts with special coatings.

- Check and clean your enclosures often to find rust early.

- Work with companies that make enclosures that do not rust.

- Teach your team how to use and take care of enclosures the right way.

Doing these things helps your enclosure work better and last longer. You will have less downtime and spend less money fixing things, so your systems keep running.

Sizing & Space Planning

Component Layout

You must plan where each part goes in your enclosure. Start by making sure the enclosure is big enough for your equipment. This helps everything fit and lets you reach each part. Leave space between parts so they do not get too hot. Air can move better this way. Keep about 20% extra space inside the enclosure. This extra room helps cool things down and makes upgrades easier.

- Put heat-making devices, like drives or power supplies, close to cool air inlets.

- Use cable trays and wiring ducts to keep cables neat and out of the way.

- Make sure you can reach important parts for repairs without moving other things.

- Plan for airflow by adding fans, vents, or heat sinks. Good airflow keeps things cool and helps equipment work better.

- Check engineering drawings before you install anything to avoid problems.

It is important to pick the right size for fans or air conditioners. If you pick units that are too small, things can get too hot and break. If you pick units that are too big, you waste energy and money. The right size keeps things cool, saves energy, and helps your enclosure last longer.

Tip: A smart layout and the right size help you avoid problems and keep your systems working well.

Expansion Flexibility

Always think about adding more equipment in the future. Planning for growth saves you money and time later. Pick a bigger enclosure than you need now so you do not have to buy a new one later. Modular designs make upgrades easy and you do not have to redo all the wiring.

| Design Aspect | Key Recommendations |

|---|---|

| Enclosure Sizing | Pick enclosures that are bigger than what you need now. This helps you avoid buying a new one later. |

| Equipment Layout | Keep equipment with the same job together. Put heat-making devices near cool air inlets. Leave space for more drives and PLC extensions. |

| Space Allocation | Leave room for more cableways, terminal blocks, and conduits. Pick wider enclosures for easier upgrades. |

| Cooling Design ( electrical enclosure fan and air) | Think about how much heat you have now and in the future. Pick cooling that can be upgraded or is big enough for later. |

| Timing Considerations | If you will add more soon, size cooling and layout for that. If you are not sure, use smaller cooling now but plan to upgrade later. |

| Economic Benefits | Planning for growth saves money over time. You do not need to buy a second enclosure and you can use cooling that can change as needed. |

You can make upgrades easier by leaving extra space in panels and switchgear. Use flexible wiring, like bus ducts or cable trays, to help with changes. Smart technology, like energy management systems, helps you use power better and plan for more needs. Always keep good records and clear labels to help with future changes.

Note: Planning for growth when you design your enclosure helps it work better, saves money, and keeps your system ready for the future.

Adequate Ventilation & Thermal Management

Recommended products

Cooling Solutions

You need good airflow and cooling in every electrical enclosure. These things help your equipment work well and last longer. If there is not enough airflow, heat and moisture can build up inside. This can make things break, not last as long, or even be unsafe.

There are different ways to control heat and moisture:

- Passive ventilation uses louvers or grills. These let hot air out. This works best for places that do not get very hot. It can make the inside cooler by 5–10 °C.

- Active ventilation uses fans with filters. You need this if your enclosure gets hotter than 150 W or is in a warm place. Fans keep things cooler than 40 °C and help your equipment work better.

- Hybrid systems use both vents and fans. The fans turn on only when needed. This saves energy and helps your equipment last longer.

- Controlling moisture is important too. Use desiccant vents or pressure-equalizing membrane vents. These keep water out and help keep IP66 or NEMA 4X ratings.

- Put vents low for air to come in and high for air to go out. This helps air move better and keeps things cool.

- Check and clean filters every few months. This is extra important if the area is dirty or rough.

Tip: Good airflow and cooling can stop over 70% of failures and help your equipment last up to 40% longer.

Linkwell Cabinet Air Conditioner

If you need strong cooling, the Linkwell Cabinet Air Conditioner is a good choice for sealed enclosures. It pulls warm air from inside the cabinet. The air goes through an evaporator coil. A refrigerant takes away the heat. The condenser sends the heat outside. This keeps dust and dirt out of your enclosure.

Some important features are:

- IP54 design with a system that gets rid of water inside, so you do not have leaks.

- Strong centrifugal fans stop hot spots and help spread heat out.

- Uses eco-friendly, high-temperature refrigerant R134a. It works even if it is as hot as 60°C.

- The design is very thin and small, so it is easy to put in and take care of.

- There are many cooling sizes, from 350W to 3500W. You can pick what you need.

- It is certified to CE, UL, and ISO9001 standards. This means it cools well and protects your equipment.

A thermostat inside controls when the cooling turns on and off. This saves energy and helps your equipment last longer. You can count on Linkwell to give you good airflow and cooling. This keeps your systems safe and helps your work go smoothly.

Environmental Protection

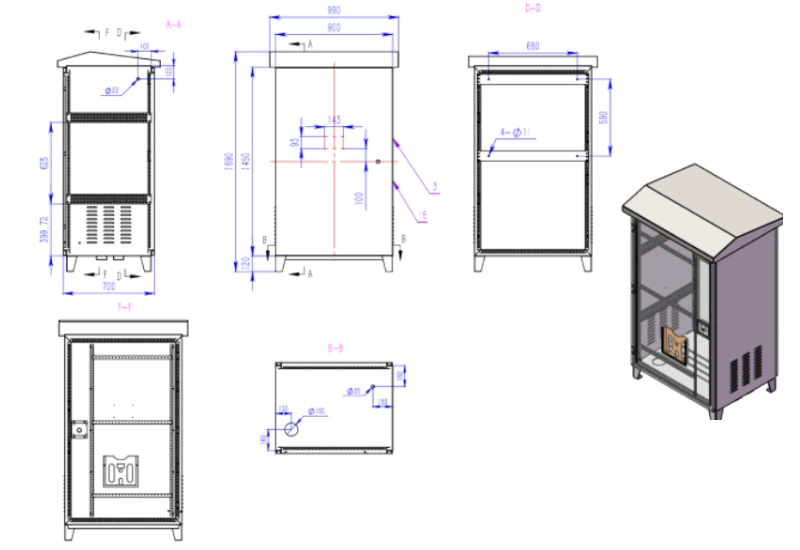

Outdoor Enclosure by Linkwell

Protecting electrical equipment outside is hard. Rain, dust, salt air, and sunlight can hurt enclosures. These things can make your equipment stop working. You need enclosures that can handle tough weather and keep your systems safe.

Linkwell outdoor enclosures help with these problems. They use strong metals or special plastics with UV coatings. Tight gaskets seal the doors well. These parts block water, dust, and sunlight. Your equipment is safe from rust, fading, and cracks.

- Chemicals in factories can damage weak materials.

- Sunlight makes plastics break and get weak.

- Salt air near the ocean causes rust quickly.

- Dust, dirt, and bumps can break seals and let water in.

- Big changes in temperature and shaking can wear out the enclosure.

Linkwell makes enclosures with fans and heaters that turn on only when needed. Fans move air and stop hot spots. Filters keep dust and dirt out. Heaters stop water drops and frost in cold weather. You can pick models with NEMA 3R, 4, or 4X ratings for different weather. These enclosures keep water and dust out, so your equipment stays dry and clean. Some models are even safe for dangerous places.

Note: The seals on your enclosure are very important. Good seals keep water and dust out, even in storms or heat.

IP & NEMA Ratings

You need to know about ratings before picking an enclosure. IP and NEMA ratings show how well an enclosure blocks dust, water, and other dangers. These ratings help you choose the right enclosure for your site.

| NEMA Rating | Approximate IP Rating | Description |

|---|---|---|

| NEMA 1 | IP10 | Indoor, dust and contact protection |

| NEMA 2 | IP11 | Indoor, drip-proof |

| NEMA 3 | IP54 | Outdoor, dust and water spray |

| NEMA 3R | IP14 | Outdoor, rain-tight and sleet resistance |

| NEMA 4 | IP56 | Indoor/outdoor, dust-tight and watertight |

| NEMA 4X | IP56 | Same as NEMA 4, plus corrosion resistance |

| NEMA 6 | IP67 | Dust and temporary water submersion |

NEMA ratings are used a lot in the United States. They cover more than just dust and water. They also include rust, ice, and gases. IP ratings are used around the world and focus on keeping out solids and liquids. Both help you pick the best enclosure for your needs.

Always check the rating for water and dust protection. For outside or tough places, pick enclosures with high ingress protection, like IP66 or NEMA 4X. These ratings mean your enclosure can handle heavy rain, dust, and even short floods. If you work in a dangerous area, look for an explosion-proof rating too.

Tip: The right rating keeps your equipment safe and working, no matter the weather or place.

Electronic Enclosure Design for Safety

Fire Resistance

Fire safety is very important in electronic enclosure design. Fires can start if wires break, things get too hot, or from outside dangers. You can lower fire risks by picking the right materials and following rules. Use steel, aluminum, or strong plastics that do not burn easily. Some places, like subway tunnels, need enclosures that can take heat over 1000°C. Rules like NFPA 130 and UL certifications tell you how to make enclosures safe from fire. These rules make sure your enclosure keeps its shape, blocks smoke, and stops fire from spreading.

Look for things like inside baffles and special coatings that stop arcs. These help keep electrical problems from spreading. Good design uses separate sections to keep problems in one place. This helps your power stay on and keeps people safe in emergencies.

| Standard | Organization Type | Region | Focus Area | Certification Type | Typical Use Cases |

|---|---|---|---|---|---|

| NEMA | Industry Association | U.S. | Performance-based (dust, water, corrosion) | Self-certification | Industrial and outdoor enclosures |

| UL | Safety Organization | North America | Fire risk and ingress protection | Third-party certification | Electrical enclosures needing verified safety |

| IEC (IP Code) | International Standards Body | Global | Ingress protection | Global certification | Automotive, aerospace, global projects |

Tip: Always pick enclosures with UL or NEMA ratings for fire safety. This makes sure your design follows the law and keeps people safe.

EMI/RFI Shielding

You need to keep electronics safe from EMI and RFI. Good design blocks signals that can cause problems or lost data. Metal enclosures made from steel, aluminum, or copper block EMI and RFI well. You can also use special coatings on plastic enclosures. This keeps them light but still blocks interference.

Add EMI/RFI gaskets to close seams and holes. These gaskets stop signals from getting in or out. For more safety, use wire mesh or mu-metal. These block low-frequency magnetic fields that metal cannot stop. New materials, like graphene composites, are light and flexible for shielding.

Follow these tips for good shielding:

- Add EMI/RFI protection early in your design.

- Use grounding to stop electrical surges.

- Keep seams tight with conductive gaskets.

- Do not mix metals that can rust.

You can also use EMI filters, honeycomb vents, and ferrite beads to cut down noise. These steps help your enclosure work well anywhere.

Note: Strong EMI/RFI shielding keeps your systems safe and your data protected.

Temperature & Humidity Control

Linkwell Enclosure Heater

It is important to keep your enclosure dry and warm. This protects sensitive electronics inside. The Linkwell Enclosure Heater helps by making the air warmer than the dew point. This stops water from forming and causing rust or electrical problems. The heater keeps things working well in cold or outdoor places. It stops freezing from happening. A thermostat inside turns the heater on only when it gets too cold. This saves energy and gives you good control.

The heater uses special technology to keep the inside climate steady. You can pick different models for many sizes and tough places. Linkwell makes these heaters strong and safe. They meet CE, UL, and RoHS safety rules. You can use them for telecom, automation, power control, and traffic signal cabinets. The heater helps your thermal management plan by keeping equipment safe all year.

- Keeps temperature above dew point to stop water drops

- Stops freezing in cold places

- Turns on only when needed to save energy

- Has options for many enclosure sizes

- Meets world safety rules for long use

Tip: Use a heater with a thermostat or hygrostat for the best way to control heat and moisture.

Condensation Prevention

Water drops inside your enclosure can hurt your equipment and make it not last as long. You need to keep humidity under 60% to stop water from building up. Use heaters, fans, or air exchangers to keep the temperature steady and above the dew point. Hygrostats and hygrotherms help you control both heat and moisture. These tools turn on heaters when humidity goes up, so you save energy.

You can also use vents or fans to balance heat and moisture. Materials like polycarbonate do not let heat escape fast, so they help stop water drops. Good seals and insulation with gaskets keep water out and stop cold spots. Check and clean your enclosures often to find water problems early.

| Control Measure | Description and Purpose |

|---|---|

| Solid state cooling units with insulation | Cool enclosures and stop heat loss and dirt |

| Slow purging with dry air | Lowers humidity and stops water drops, good for wet places |

| Dynamic air mixing systems | Mix warm and cool air to keep heat and moisture even |

| Sealed enclosures with internal heating | Stop dust from getting in and control heat and moisture |

| Keeping humidity below 60-70% | Use heaters with hygrostats or hygrotherms to keep moisture low and stop water drops |

Note: Watching humidity and temperature helps you pick the right tools and stop water drops. Use both heaters and coolers for better control when the weather changes.

Power Distribution & Cable Management

Linkwell Power Distribution Box

You need a strong power system to keep your electrical panel safe. The Linkwell Power Distribution Box helps protect your equipment and team. Circuit breakers or fuses stop power if the current gets too high. This keeps things from overheating or catching fire. Short-circuit protection works fast to stop damage. Good grounding sends fault currents away. This lowers the chance of electric shock.

Fire-resistant enclosures and insulation keep people and equipment safe. Surge protection devices block voltage spikes from lightning or other problems. The Linkwell Power Distribution Box uses materials that do not rust. It has IP65 or IP66 ratings, so you can use it inside or outside. You can pick the size and layout that fits your panel or control panels. The box meets top standards like UL 508A and IEC 61439. This helps you feel safe and sure.

Tip: Real-time fault monitoring and certified parts help you avoid failures and cut downtime.

Organized Wiring

Organized wiring makes your electrical panel easier to fix and safer to use. Use wiring diagrams to plan cable routes and future changes. Pick enclosures with enough space for cables and room to grow. Always label wires and hardware clearly. This helps you and others understand the panel and work safely.

- Bundle cables with ties, but do not make them too tight. This stops damage.

- Keep power and data cables apart to avoid interference.

- Use cable management tools like clamps, ducts, and grommets to keep cables neat and safe.

- Put vertical cable managers on the back of cabinets for better order and easy access.

- Label both ends of each cable with matching numbers or colors for clear labelling.

- Keep a list of cable endpoints for easier management.

Clear labels and neat wiring make fixing problems faster. You can find cables quickly and fix issues, which cuts downtime. Good cable management also helps air flow, keeping equipment cool and working well. Check labels and cable bundles often to keep your system in good shape.

Note: Organized wiring and clear labels are important for long-lasting safety and reliability in every electrical panel enclosure.

Lighting & Accessibility

Linkwell Enclosure Light

You need good lighting inside electrical enclosures to work safely. The Linkwell Enclosure Light uses LED panels that are bright and do not make shadows. This helps you see every part clearly. You do not need a flashlight. A German company found that workers found wiring problems faster. A telecom company fixed issues 22% quicker after using these lights in many cabinets.

The LED panels have aluminum backs and heat sinks. These keep the lights cool and steady, even if you use them for a long time. The panels are EMC compliant. This means they do not mess up signals in telecom or control systems. You can pick different ways to mount the lights and choose the voltage you need. This makes it easy to install them anywhere.

Tip: Micro-prismatic diffusers in the Linkwell Enclosure Light cut down glare. They help protect your eyes from getting tired, especially in control rooms and data centers.

The lights last more than 50,000 hours and have surge protection. You can trust them to work all day and night. Reports from Malaysia show these LED panels lasted longer than dome lights. There were no failures in 18 months.

Maintenance Access

Always design your enclosure so it is easy to fix and check. Good lighting helps you look at wires, find rust, and spot overheating fast. You can use quick-release latches or panels that open without tools. This lets you get inside in seconds. You can fix problems quickly and have less downtime.

Here is a table of recommended lighting and accessibility features for modern enclosures:

| Feature Category | Recommendations and Features |

|---|---|

| Types of Junction Boxes | Standard (metal/plastic, knockouts), Weatherproof (sealed, UV resistant), Specialty (LED, smart, high-voltage) |

| Installation Considerations | Use boxes rated for fixture weight and environment, professional installation, built-in cable clamps |

| Accessibility | Easy access for maintenance and troubleshooting |

| Maintenance | Routine inspections for loose connections, corrosion, overheating |

| Emerging Trends | Smart boxes with remote monitoring, eco-friendly materials |

Note: Planning for good lighting and easy access makes inspections safer and faster. This helps protect your equipment and your team.

Mounting & Installation

Secure Mounting

You must make sure your electrical enclosure stays in place. It should not move, no matter where you put it. Pick the right mounting system for your area. Wall, floor, and pole mounting all need different steps. For wall or pole mounting, use strong brackets or flanges. These must fit the size and weight of your enclosure. Always check if the wall or pole can hold the load.

Use stainless steel hinges and latches to stop rust. These also help keep the door closed tight. Gaskets are important for blocking dust and water. Choose silicone gaskets if you expect a lot of moisture or chemicals. When you put in the enclosure, check that all screws are tight. Make sure the box sits flat and level. This stops leaks and keeps your equipment safe.

Tip: Always follow the instructions for mounting. This helps you avoid problems with grounding, sealing, or support.

Cable management is also important for secure mounting. Use clips and restraints to keep cables neat. This stops cables from getting damaged. Leave enough space for connectors and upgrades later.

Site Adaptability

Every site is different and has its own problems. You might have little space, bumpy ground, or bad weather. You need to pick enclosures and mounts that work for these places. Linkwell gives you many mounting choices, like wall, pole, and floor kits. You can pick steel, aluminum, or non-metallic enclosures to fit your site.

Check the enclosure’s NEMA or UL ratings to see if it fits your area. For outdoor places, surge protection and good grounding are very important. Use sealed cable entries and weatherproof hardware to keep out water and dust. Plan for easy access so you can check and fix your enclosure without trouble.

| Challenge | Solution Example |

|---|---|

| Space Constraints | Use compact or modular enclosures |

| Corrosive Environs | Choose stainless steel hardware |

| Uneven Surfaces | Adjustable mounting brackets |

| Harsh Weather | Weatherproof seals and gaskets |

Linkwell’s flexible options help you meet tough site needs. They keep your systems safe and working well.

Common Pitfalls

Moisture Ingress

Water can damage your electrical enclosure and break equipment. Problems happen when water gets inside from bad seals or wrong spots. If you do not seal things right, you might get rust, shorts, and have to stop work. Here are mistakes you should not make:

- You do not check gaskets and seals for cracks or wear.

- You put enclosures in damp places but forget heaters or vents.

- You use enclosures with low NEMA or IP ratings outside.

- You do not look for leaks or water drops often.

Tip: Always pick enclosures with high IP or NEMA ratings for wet or dusty spots. Check seals and gaskets a lot. Linkwell has outdoor enclosures with strong seals and heaters to keep water out. Their team can help you find the best one for your place.

Overlooking Future Needs

Sometimes you only think about what you need now and forget about upgrades. This can make panels crowded, airflow bad, and changes cost more later. Watch out for these mistakes:

- You pick enclosures that are too small for new parts later.

- You do not plan for more circuits or bigger power boxes.

- You skip clear labels, so upgrades and fixes are harder.

- You use cables that are too short for moving or adding things.

| Mistake | How to Avoid It |

|---|---|

| Small enclosure size | Pick bigger or modular enclosures |

| Missing circuit capacity | Plan for more circuits and upgrades |

| Poor labeling | Use clear, standard labels |

| Bad cable management | Leave room for more wires |

Note: Think about growth when you design your enclosure. Linkwell has enclosures you can change and gives expert help. Their team helps you pick panel sizes, add space, and label things for easy upgrades.

You can stop most problems by checking your design, looking at ratings, and planning for the future. Regular checks and good records keep your system safe and ready for changes.

You can do well with electrical enclosure design in 2025 if you focus on safety. You should follow strict rules and think about what you might need later. Linkwell is a trusted company. Their products have top certifications like UL 508A, NFPA 70, and IEC 61439. You get help from their team all over the world. They deliver fast and make custom products for many jobs.

| Certification | Region | Focus Area |

|---|---|---|

| UL 508A | U.S. & Canada | Control Panel Safety |

| NFPA 70 | U.S. & Canada | Electrical Installation |

| IEC 61439 | International | Low-voltage Assemblies |

If you want expert help or more info, go to Linkwell’s website and talk to their team.

FAQ

What is the best way to choose the right enclosure size?

You should list all your components first. Add at least 20% extra space for airflow and future upgrades. Check the manufacturer’s sizing guide for help. If you need advice, Linkwell’s team can assist you.

How do you prevent overheating inside an enclosure?

You can use fans, vents, or a cabinet air conditioner. Place heat-producing parts near cool air inlets. Clean filters often. For tough environments, Linkwell offers certified cooling solutions.

Why are IP and NEMA ratings important?

These ratings show how well your enclosure blocks dust and water. High ratings mean better protection. Always match the rating to your site’s needs. For outdoor or wet areas, pick IP66 or NEMA 4X.

Can you use enclosure heaters in wet locations?

Yes, you can use heaters with IP65 or higher ratings. These models resist dust and water. Linkwell’s enclosure heaters work well in damp or cold places.

How often should you inspect seals and gaskets?

Check seals and gaskets every three months. Look for cracks or wear. Replace them if you see damage. Regular checks help prevent leaks and keep your equipment safe.